A copper-based coordination polymer and its preparation method and its application as a gangue mineral inhibitor in the flotation of copper-nickel sulfide ore

A technology of coordination polymer and coordination polymerization, applied in flotation, solid separation and other directions, can solve problems such as difficulty in flotation separation, and achieve the effects of high-efficiency flotation separation, reduction of beneficiation cost, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

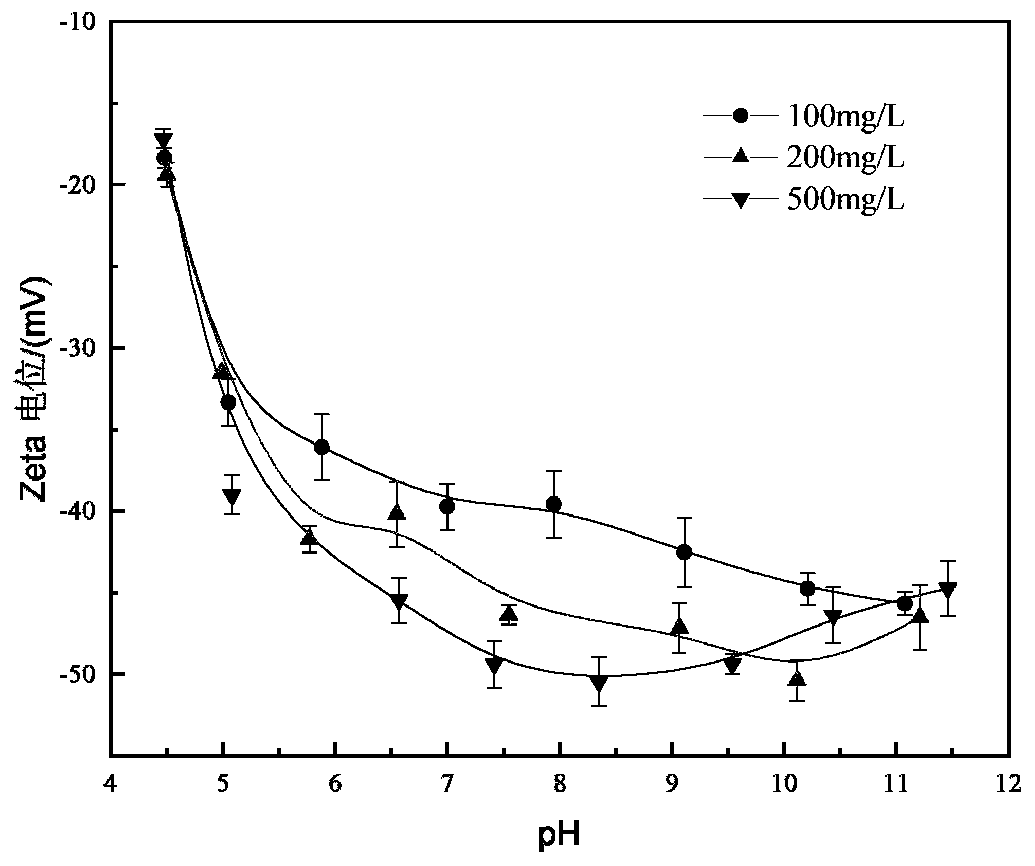

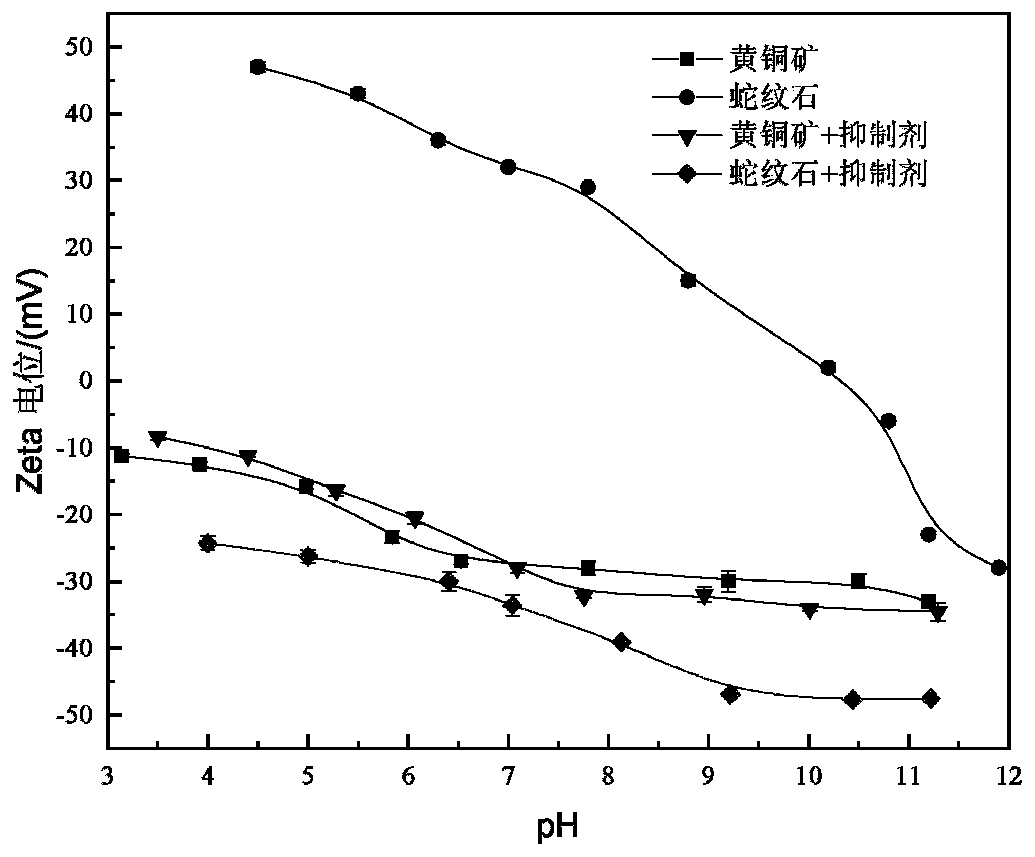

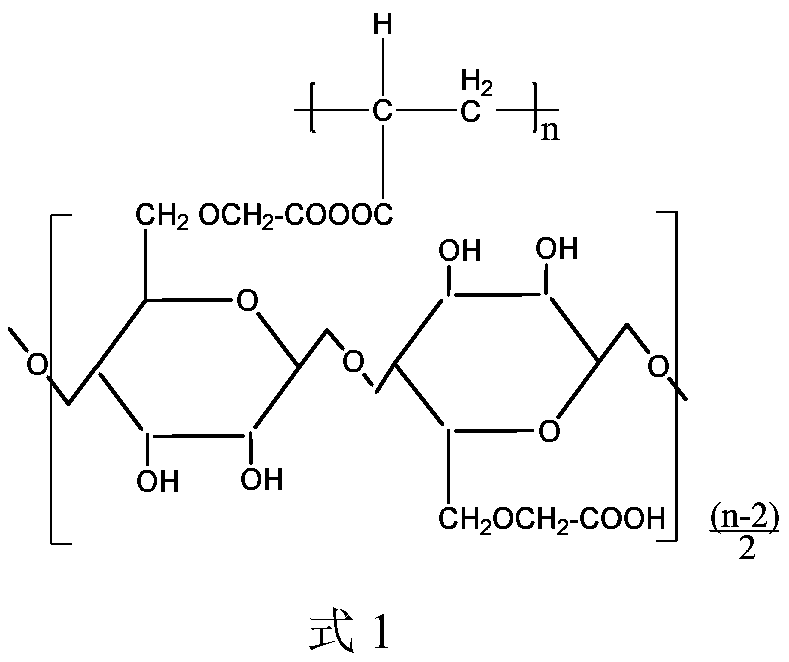

[0041]Weigh 0.001mol of sodium polyacrylate (molecular weight about 2000) and 0.001mol of phosphorus pentachloride into a 500mL flask, add 300mL of chloroform as a solvent, stir and react at room temperature for 30min, and then purify the product and dry it in vacuum at 40°C get the product. Then add the product and 0.002mol carboxymethyl cellulose into a 500mL flask, add 0.22g sodium hypophosphite and 300mL glycerin, place in a sand bath heating pot, stir with a magnet and heat to 120°C, keep it warm for 30min, and then purify the product Then place it at 50°C for 24 hours in vacuum to obtain polyacrylic acid-carboxymethyl cellulose mixed anhydride. Put the mixed acid anhydride in a flask, add water to make the mass concentration 40%, then place it in a constant temperature water bath, stir it with a magnet, heat it to 80°C and keep it warm for 30 minutes. Weigh 0.2mol of copper sulfate to make a solution with a concentration of 3%, add it dropwise to the mixed anhydride at ...

Embodiment 2

[0046] Weigh 0.0015mol of sodium polyacrylate (molecular weight about 3500) and 0.0015mol of phosphorus pentachloride into a 500mL flask, add 300mL of chloroform as a solvent, stir and react at room temperature for 30min, and then purify the product and dry it in vacuum at 40°C get the product. Then add the product and 0.003mol carboxymethyl cellulose into a 500mL flask, add 0.18g sodium hypophosphite and 280mL glycerin, place in a sand bath heating pot, stir with a magnet and heat to 120°C, keep warm for 30min, and then purify the product Then place it at 50°C for 24 hours in vacuum to obtain polyacrylic acid-carboxymethyl cellulose mixed anhydride. Put the mixed acid anhydride in a flask, add water to make the mass concentration 45%, then place it in a constant temperature water bath, stir it with a magnet, heat it to 80°C and keep it warm for 30 minutes. Weigh 0.2mol of copper sulfate to make a solution with a concentration of 5%, add it dropwise to the mixed anhydride at ...

Embodiment 3

[0051] Weigh 0.002mol of sodium polyacrylate (molecular weight about 4000) and 0.002mol of phosphorus pentachloride into a 500mL flask, add 300mL of chloroform as a solvent, stir and react at room temperature for 30min, and dry the product in vacuum at 40°C after purification get the product. Then add the product and 0.004mol carboxymethyl cellulose into a 500mL flask, add 0.31g sodium hypophosphite and 340mL glycerin, place in a sand bath heating pot, stir with a magnet and heat to 120°C, keep it warm for 30min, and then purify the product Then place it at 50°C for 24 hours in vacuum to obtain polyacrylic acid-carboxymethyl cellulose mixed anhydride. Put the mixed acid anhydride in the flask, add water to make the mass concentration 40%, then place it in a constant temperature water bath, stir it with a magnet, heat it to 80°C and keep it warm for 30 minutes. Weigh 0.2mol of copper sulfate to make a solution with a concentration of 5%, add it dropwise to the mixed anhydride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com