A calcium-containing or silicate gangue mineral flotation inhibitor and its preparation method and application

A technology for gangue minerals and silicates, applied in the field of comprehensive utilization of tungsten ore resources, can solve the problems of difficult flotation separation, low concentrate grade and recovery rate, and large consumption, achieve high-efficiency flotation separation, and reduce beneficiation costs. , the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

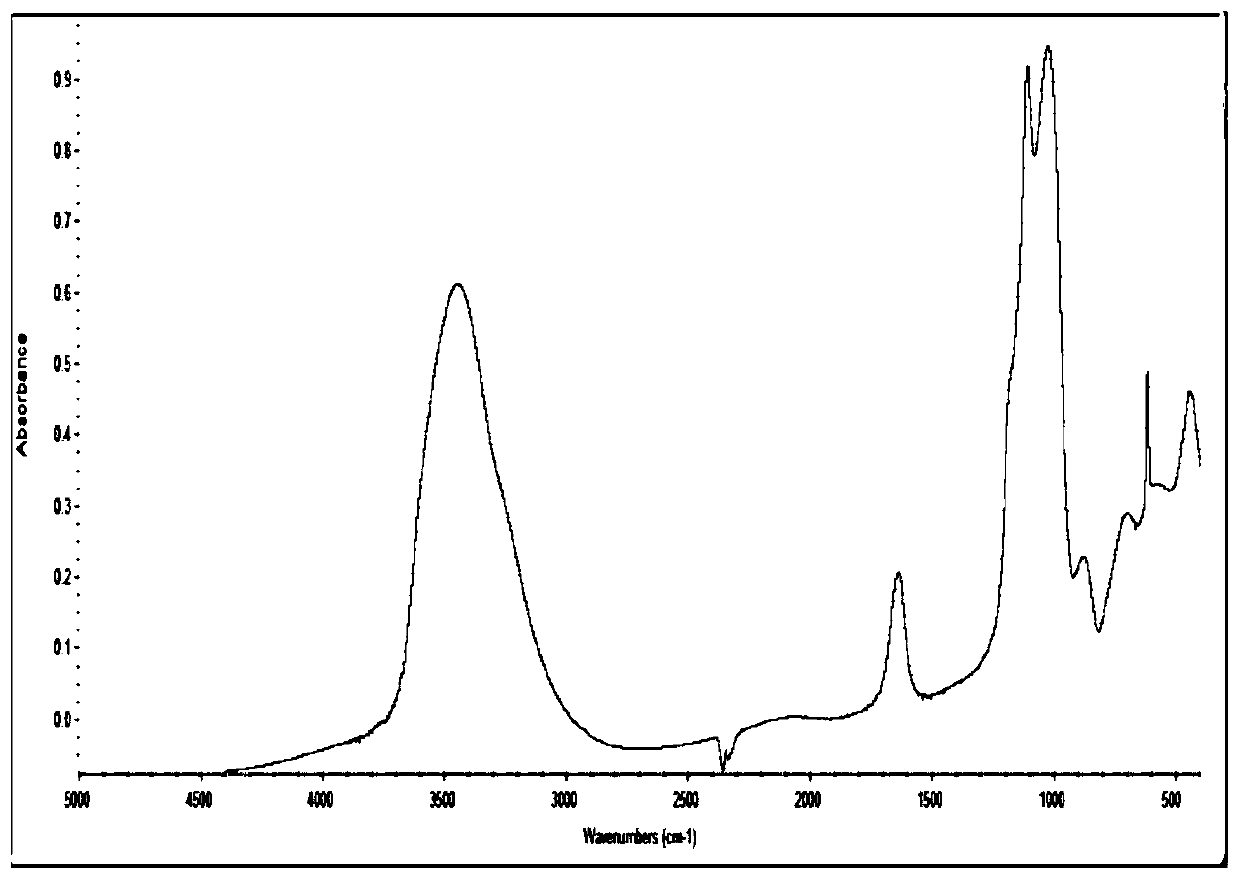

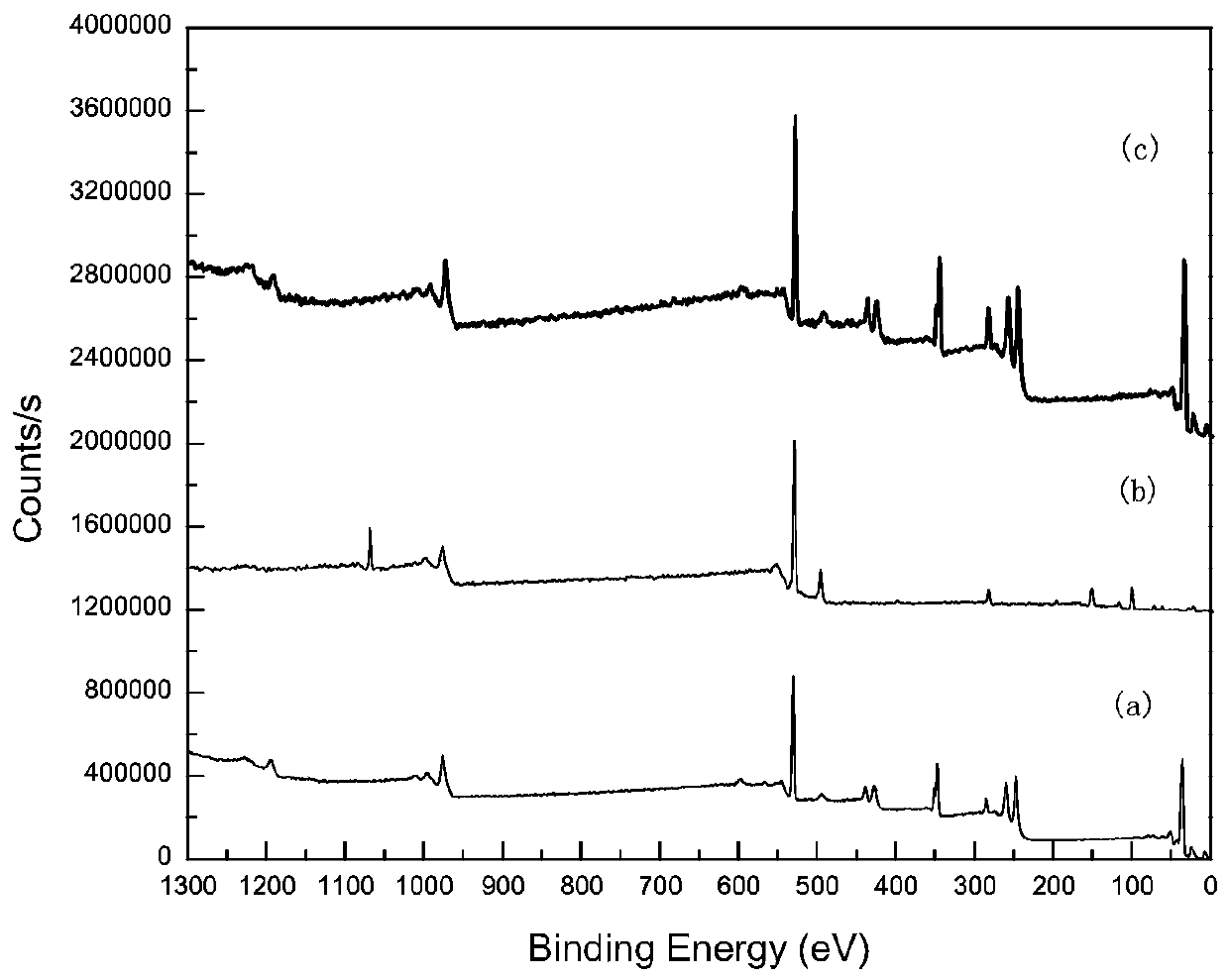

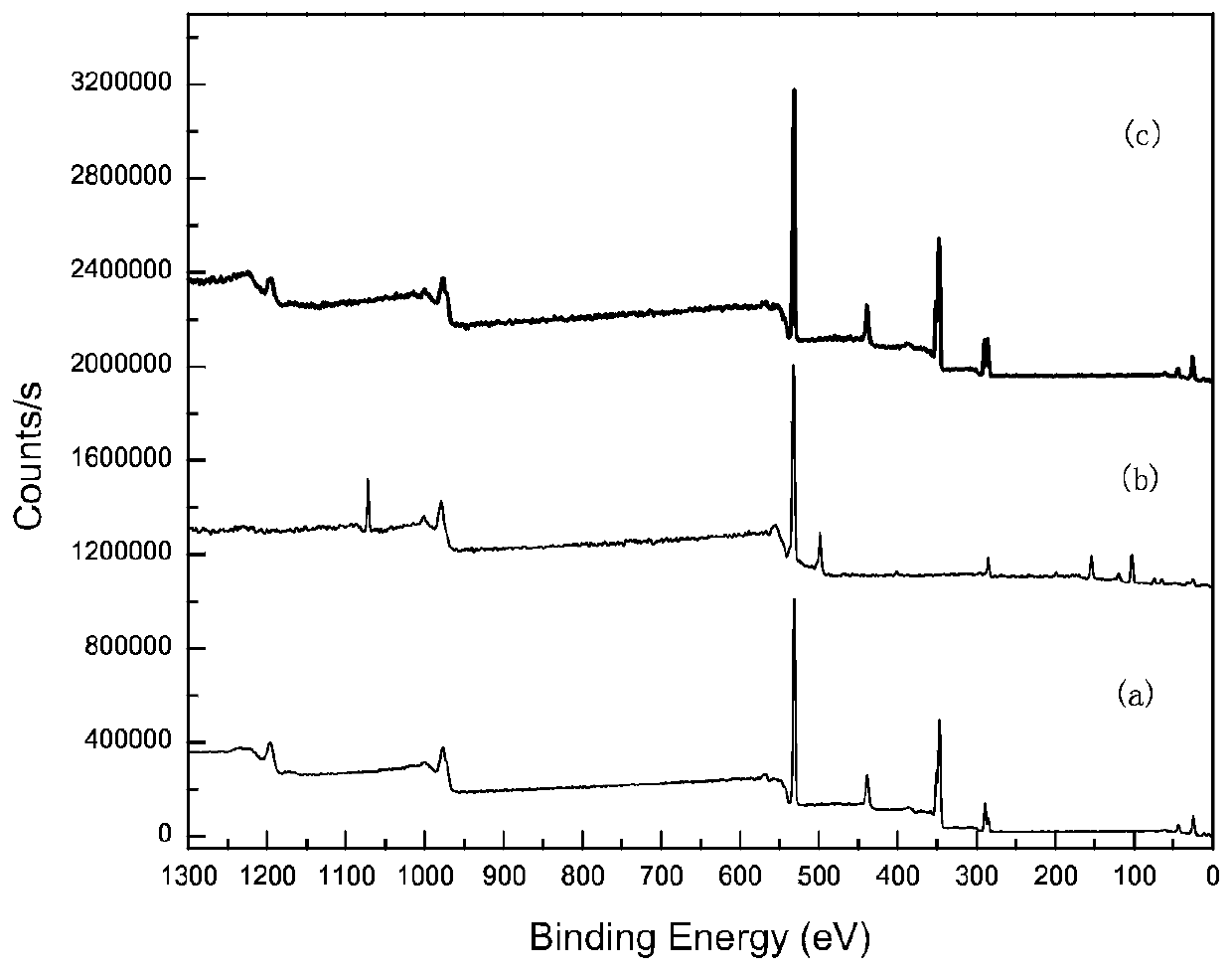

Method used

Image

Examples

Embodiment 1

[0034] Add 375g of diatomite with a particle size below 37 μm and 100mL of 40% caustic soda solution into the autoclave, control the temperature of the autoclave at 200°C and the pressure at 15MPa, and react for 1 hour. After the reaction, filter to obtain the filtrate. Then, 180 g of aluminum sulfate powder was added to the filtrate, and stirred at 100° C. for 10 min to obtain the metal ion inorganic polymer inhibitor.

[0035] Use the obtained metal ion inorganic polymer inhibitor to treat Shizhuyuan tungsten tin molybdenum bismuth polymetallic ore tungsten ore, the raw material used is black and white tungsten mixed flotation rough concentrate, the rough concentrate contains WO 3 The phase analysis shows that the tungsten-containing minerals are mainly scheelite, wolframite, and a small amount of tungsten, and the gangue minerals are mainly calcite, fluorite, garnet, mica and other calcium-containing minerals. Add the metal ion inorganic polymer inhibitor into the pulp, adj...

Embodiment 2

[0038] Add 375g of diatomite with a particle size below 37 μm and 100mL of 35% caustic soda solution into the autoclave, control the temperature of the autoclave at 100°C and the pressure at 5MPa, react for 2 hours, and filter to obtain the filtrate after the reaction. Immediately, 90 g of aluminum sulfate powder was added to the filtrate, and stirred at 50° C. for 30 min to obtain the metal ion inorganic polymer inhibitor.

[0039] The obtained metal ion inorganic polymer inhibitor is used to treat fine tungsten slime from Xingluokeng tungsten mine in Ninghua. 3The phase analysis shows that the tungsten-containing minerals are mainly scheelite, wolframite, and a small amount of tungsten, and the gangue minerals are mainly feldspar, calcite, garnet, mica, quartz and other minerals. Add the metal ion inorganic polymer inhibitor into the pulp, adjust the slurry for 5 minutes and then add it to the flotation column. After one rough and two fines, the WO-containing 3 It is 71.41%...

Embodiment 3

[0042] Add 375g of diatomite with a particle size below 37 μm and 100mL of 40% caustic soda solution into the autoclave, control the temperature of the autoclave at 150°C and the pressure at 10MPa, react for 2 hours, and filter to obtain the filtrate after the reaction. Then 45g of aluminum sulfate powder was added to the filtrate, and stirred at 80°C for 20 minutes to obtain the metal ion inorganic polymer inhibitor.

[0043] Use the obtained metal ion inorganic polymer inhibitor to treat Yaogangxian tungsten tin molybdenum bismuth polymetallic ore tungsten ore. The raw material used is black and white tungsten mixed flotation rough concentrate, the rough concentrate contains WO 3 The phase analysis shows that the tungsten-containing minerals are mainly wolframite, scheelite, and a small amount of tungsten, and the gangue minerals are mainly fluorite, calcite, mica, garnet, quartz and other minerals. Add 150g / t metal ion inorganic polymer inhibitor into the pulp, adjust the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com