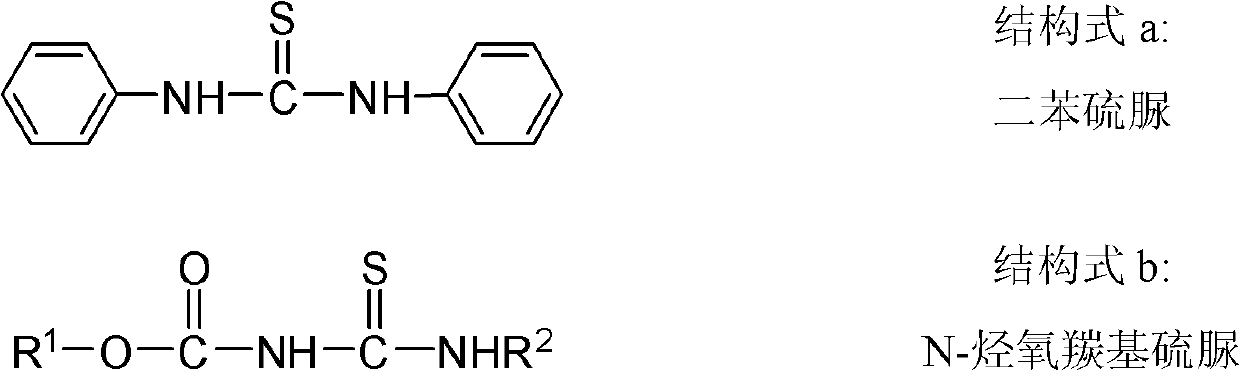

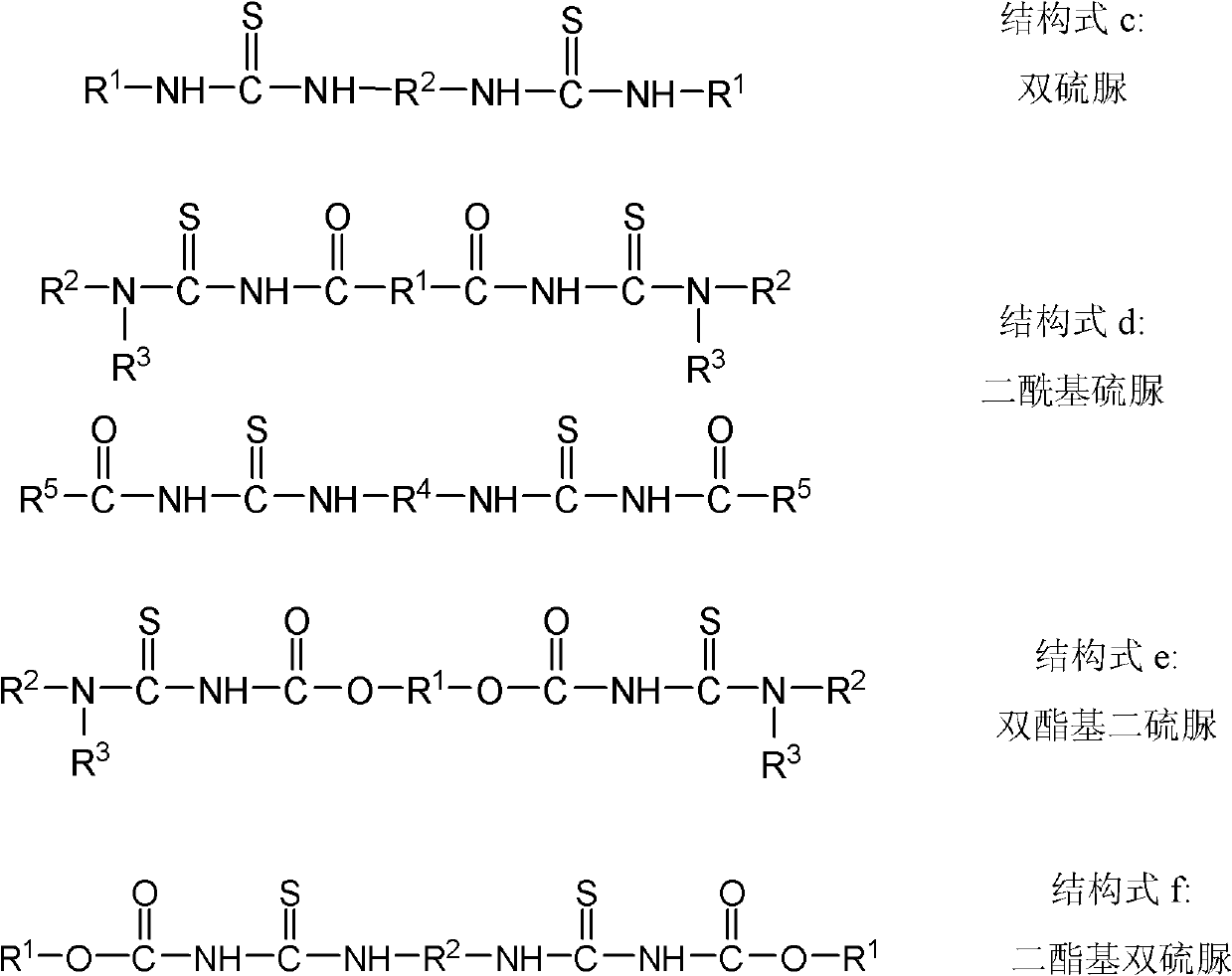

Thiourea compound and preparation thereof and application thereof to metal ore floatation

A compound, thiourea technology, applied in flotation, organic chemistry, solid separation, etc., can solve the problems of insufficient mineral surface action, inconvenient addition, poor dispersion, etc., to improve the comprehensive recovery rate of metals, flotation The effect of improved recovery rate and weak collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

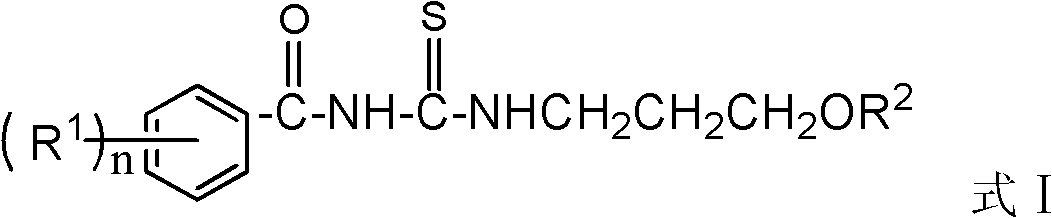

[0029] The preparation of embodiment 1N-benzoyl-N'-butoxypropyl thiourea

[0030] Slowly add 131.2 parts of γ-butoxypropylamine to the dichloromethane solution containing 163.2 parts of N-benzoyl isothiocyanate at a reaction temperature of -5 to 20°C under stirring conditions, and stir for 30 minutes , and then warmed up to room temperature and reacted for 1 hour. The solvent dichloromethane was distilled off under reduced pressure to obtain 290.5 parts of N-benzoyl-N'-butoxypropylthiourea as a yellow oily product with a product purity of 91.5%.

Embodiment 2

[0031] The preparation of embodiment 2N-benzoyl-N'-butoxypropyl thiourea

[0032] Slowly add the acetone solution containing 131.2 parts of γ-butoxypropylamine to the acetone solution containing 163.2 parts of N-benzoyl isothiocyanate at a reaction temperature of 10-20°C under stirring conditions, and the addition is complete Then reflux and stir the reaction for 2 hours. The solvent acetone was distilled off under reduced pressure to obtain 260.4 parts of N-benzoyl-N'-butoxypropylthiourea as a yellow oily product with a product purity of 94.6%.

Embodiment 3

[0033] The preparation of embodiment 3N-benzoyl-N'-isopropoxypropyl thiourea

[0034] Slowly add 117.2 parts of γ-isopropoxypropylamine to the dichloromethane solution containing 163.2 parts of N-benzoyl isothiocyanate at a reaction temperature of -5 to 20°C under stirring conditions, and stir to react 30min, then warmed up to room temperature and reacted for 1.5 hours. The solvent dichloromethane was distilled off under reduced pressure to obtain 270.2 parts of N-benzoyl-N'-isopropoxypropylthiourea as a yellow oily product with a product purity of 93.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com