A square nut automatic chamfering device and processing method

A technology of a chamfering device and a square nut, which is applied in the mechanical field, can solve the problems of increasing process complexity, low efficiency, and iron filings, etc., and achieves the effects of fast operation, safe processing, and high-precision chamfering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

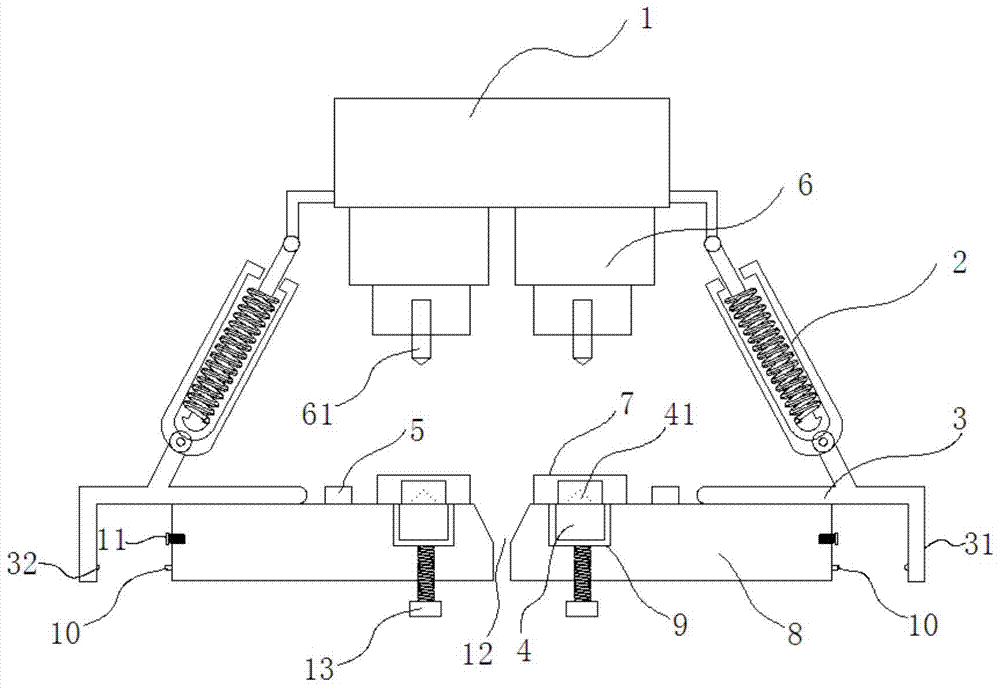

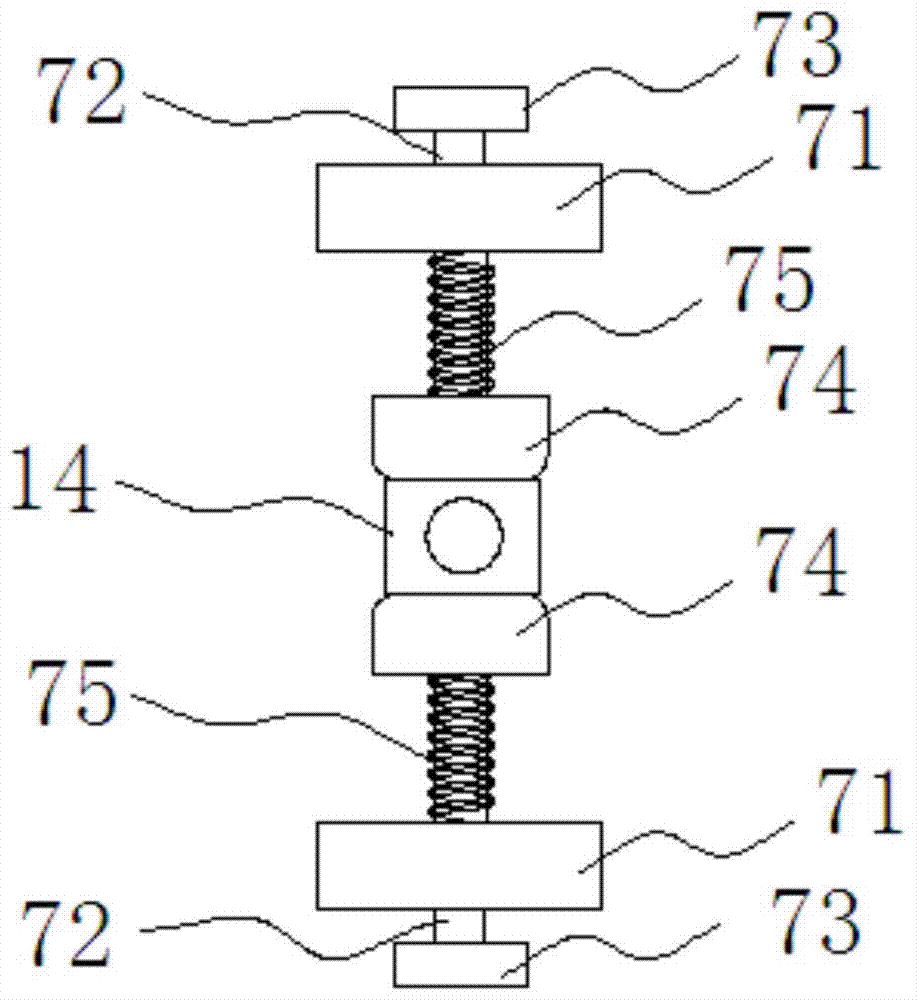

[0024] like figure 1 As shown, an automatic chamfering device for a square nut includes a punch slider 1, a ball guide bush 2, a feeding slider 3, a lower die 4, a material retaining block 5, an upper die 6 and a damping mechanism 7, and the automatic chamfering The device is installed on the punch base 8. The square nut automatic chamfering device described in this embodiment includes two sets of upper mold 6, lower mold 4 and damping mechanism 7 which can work simultaneously. The punch base 8 is provided with two lower die holes 9 located on the same straight line, the lower die 4 is placed in the lower die holes 9, the top of the lower die 4 is provided with a lower punch 41, and the bottom of the lower die hole 9 is provided with an adjusting bolt 13, used to adjust the height of the lower die 4 and the lower punch 41. A blanking hole 12 is provided in the middle of the punch base 1 (between the two lower dies 4 ) for transporting the processed square nut 14 .

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com