Rice hulling device

A technology of a rice and feeding device, which is applied in the directions of grain pod removal, grain hulling, and grain degermination, etc., can solve the problems of rice overflow, excessive rice feeding, fixed wind direction of the air blower, etc. The effect of avoiding excessive feeding and facilitating periodic unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

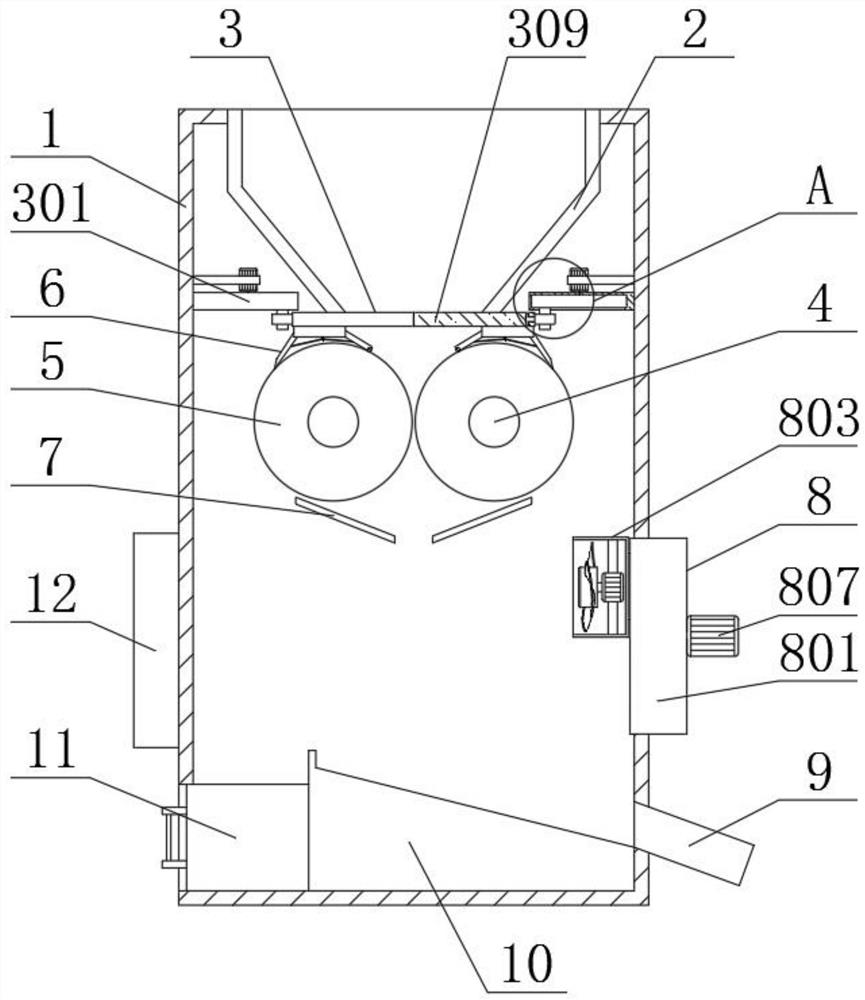

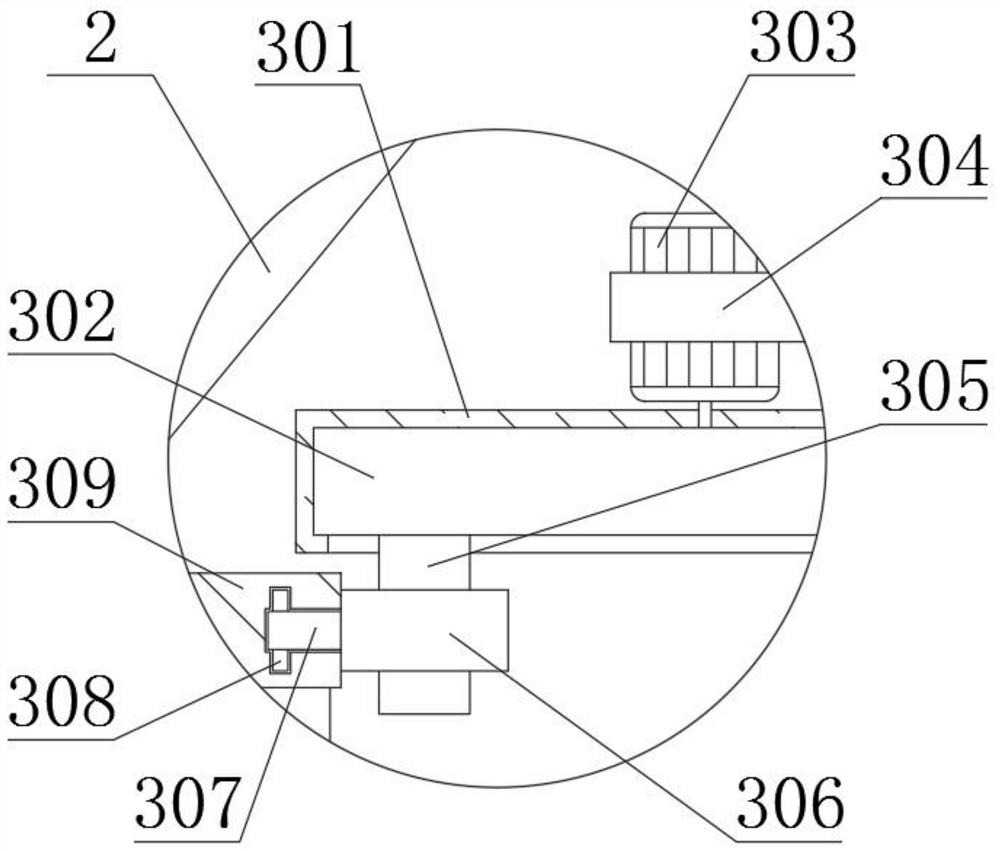

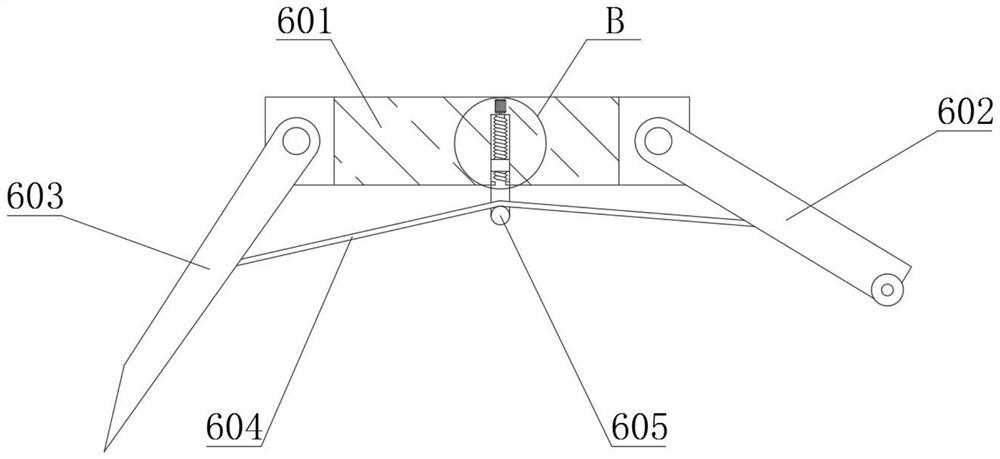

[0025] see Figure 1-6 , the present invention provides a technical solution:

[0026] A rice hulling device, comprising a processing body 1, a feeding hopper 2 is fixedly connected to the inside of the top of the processing body 1, and a feeding device 3 is arranged at the bottom of the feeding hopper 2, and the feeding device 3 includes a fixed seat 301, a rotating Disc 302, first motor 303, fixed block 305, fixed ring 306 and material distribution plate 309, the bottom end of discharge device 3 is provided with roller protection device 6, and roller protection device 6 comprises fixed plate 601, baffle plate 602, The scraper 603, the elastic belt 604 and the buckle 605, the inner side of the fixed plate 601 is connected with the baffle 602 and the scraper 603, the elastic belt 604 is fixedly connected between the baffle 602 and the scraper 603, the bottom of the fixed plate 601 A belt buckle 605 is slidingly connected to the inner side, and the elastic belt 604 is passed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com