Front and back mold inclined top release mold and machining method thereof

A technology of inclined top and rear mold, which is applied in the field of injection molding processing, can solve the problems of incomplete molding and inapplicability, and achieve the effect of excellent mechanical logic relationship, good use effect and guaranteed yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

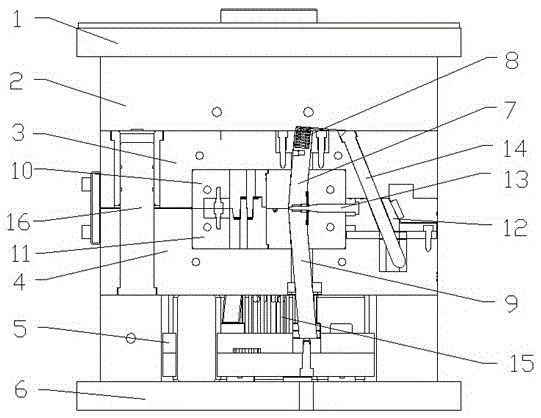

[0031] The invention discloses a front and rear inclined top demoulding mold and a processing method thereof which are suitable for forming and demoulding injection molded parts provided with annular undercut surfaces.

[0032] like figure 1 Shown, a kind of front and rear mold slope top demoulding mold comprises front mold and rear mold, is provided with front mold chute in the described front mold, is movably provided with front mold slope 7 in the described front mold chute, A rear mold chute is provided in the rear mold, and a rear mold slant 9 is movably arranged in the rear mold chute. The front mold slant 7 and the rear mold slant 9 cooperate to complete the molding of the annular undercut surface of the injection molded part.

[0033] The end of the front mold slope top 7 in contact with the bottom of the front mold slope is also provided with a reset assembly for the elastic reset of the front mold slope top 7 .

[0034] The front mold includes a front mold base 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com