Laminated silk glass plate and its production process

A production process and glass plate technology, applied in the field of decorative materials, can solve the problems of poor decorative effect and aesthetics to be improved, and achieve the effect of ensuring safety and decoration, good decorative effect and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

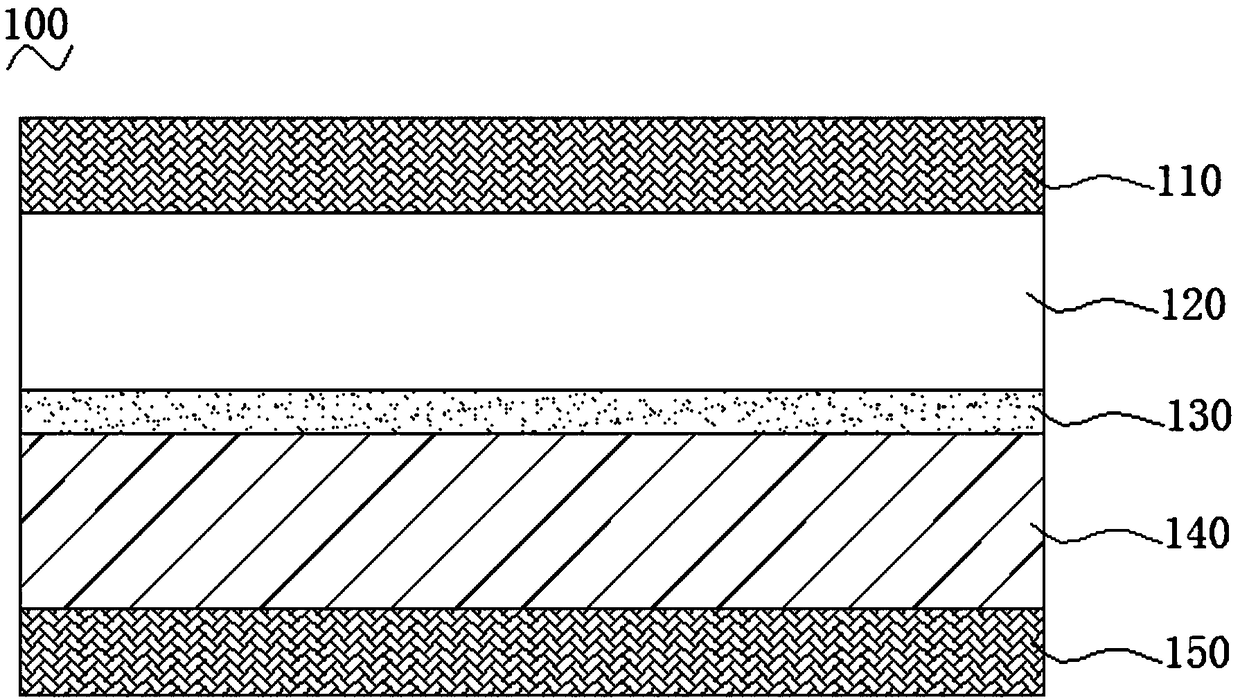

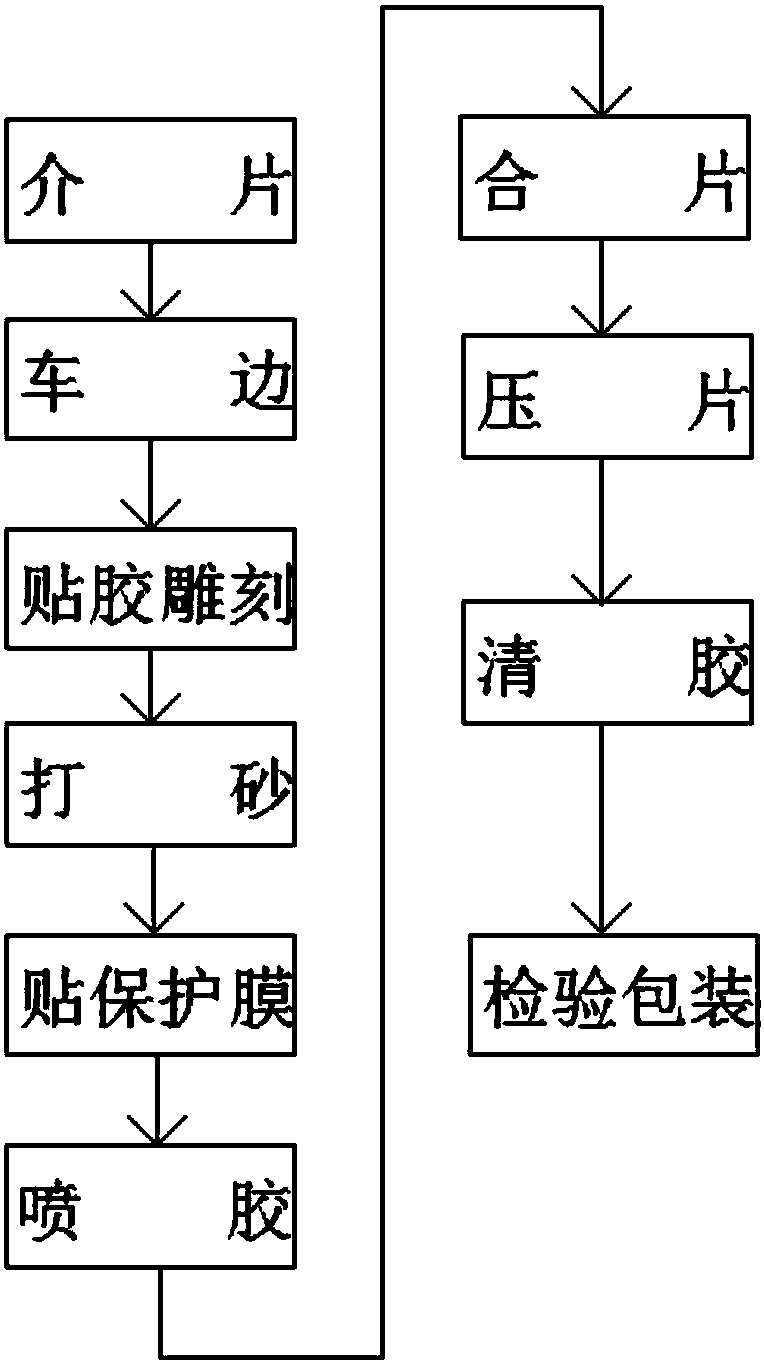

[0034] Such as figure 1 and figure 2 Shown are the structural schematic diagram and the production process flow chart of the laminated silk glass plate of the present invention, respectively.

[0035] The laminated silk glass plate 100 includes a first protective film layer 110, a first glass base layer 120, a sprayed glue layer 130, a second glass base layer 140 and a second protective film layer 150 which are stacked in sequence, and the sprayed glue layer 130 is sprayed on the first Between a glass base layer 120 and the second glass base layer 140 to bond the first glass base layer 120 and the second glass base layer 140, the first protective film layer 110 is pasted on the side of the first glass base layer 120 away from the glue spray layer 130, the second The protective film layer 150 is pasted on the side of the second glass base layer 140 away from the glue spray layer 130, and the glue spray layer 130 is spread out in a silk shape; the first glass base layer 120 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com