Thruster installation process

An installation process and propeller technology, which is applied in transportation and packaging, ship construction, ship design, etc., can solve problems such as difficulty in propeller installation, and achieve the effects of avoiding berth modification, reducing installation costs, and solving installation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

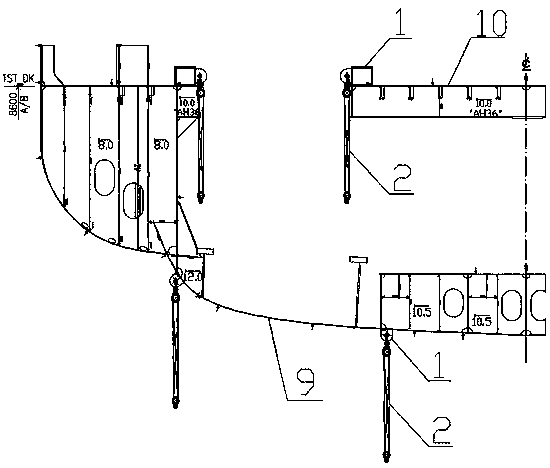

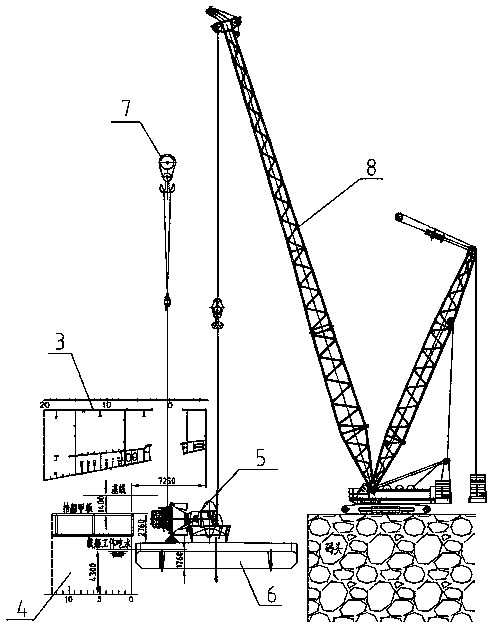

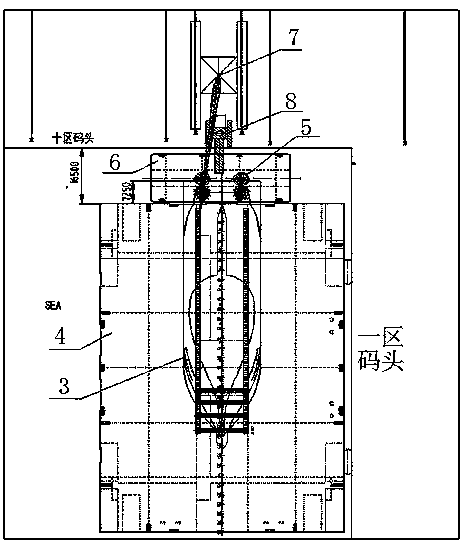

[0019] Such as Figure 1 to Figure 3 As shown, the propeller installation process method, the specific steps are: A. Set up a temporary eye 1 for propeller installation on the ship's outer plate and deck area during the berth loading stage, and pre-hook the drag chain hoist 2 in advance; Step B 1. The ship 3 is towed into the launching barge 4, and the stern of the ship protrudes out of the launching barge 7.25 meters, and then the launching barge 4 is moved to the wharf in the first area, and its stern is 16.5 meters away from the wharf in the tenth area; step C, using a 150-ton tower crane 7 to move The propeller 5 is placed on the square barge 6, and the four corners are fixed with sealing ropes; step D, move the square barge 6 to the edge of the lower water barge 4, and use the height difference between the two to start using the 150-ton tower crane 7 and the 160-ton crawler crane 8 Cooperate with hoisting the propeller 5 to turn over; step E, hoist the propeller 5 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com