Rotary pay-off rack

A technology of rotating frame and pay-off frame, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of time-consuming and labor-intensive pay-off frames, low production efficiency, and dead bends, etc., and achieves convenient operation , High production efficiency and smooth wire release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

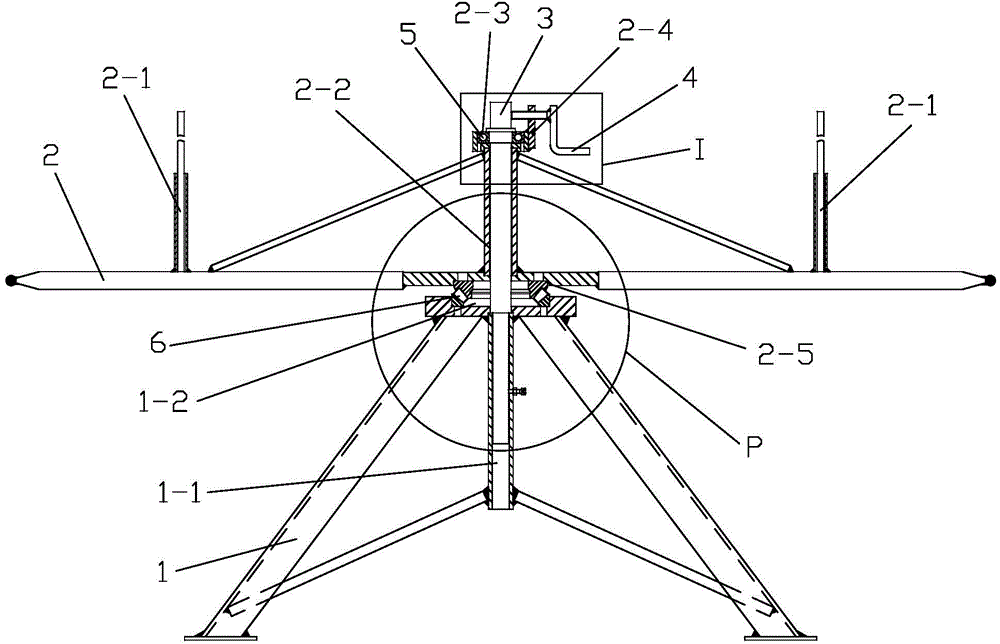

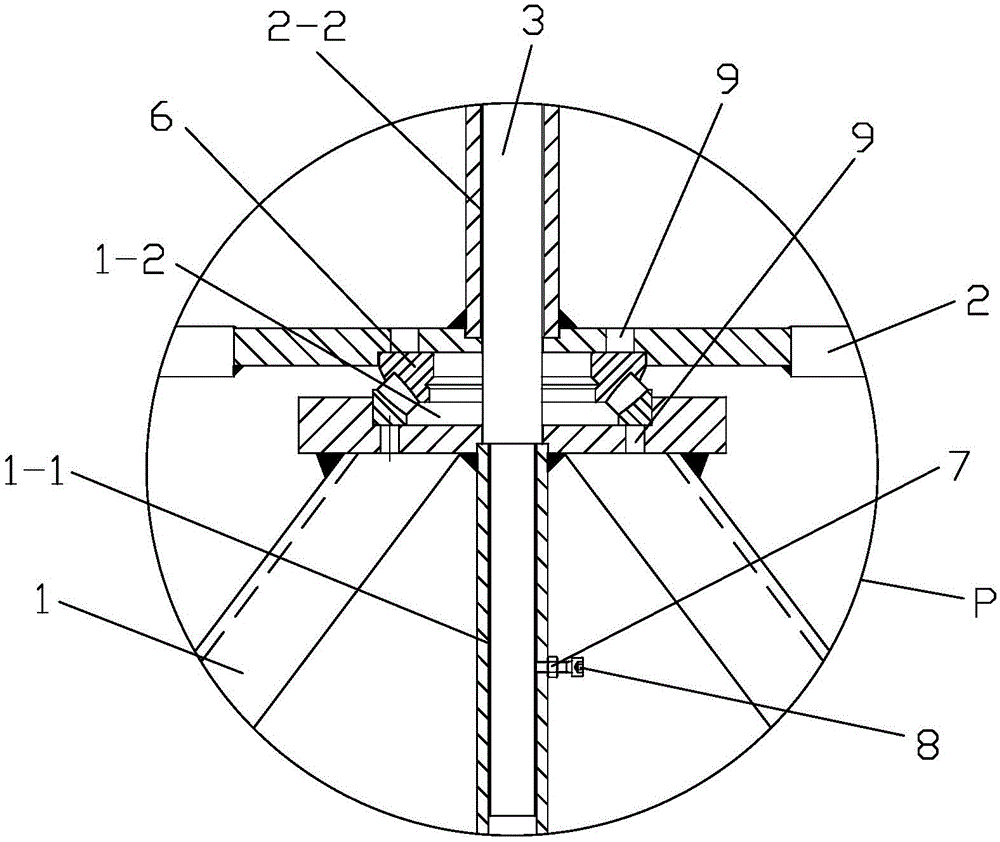

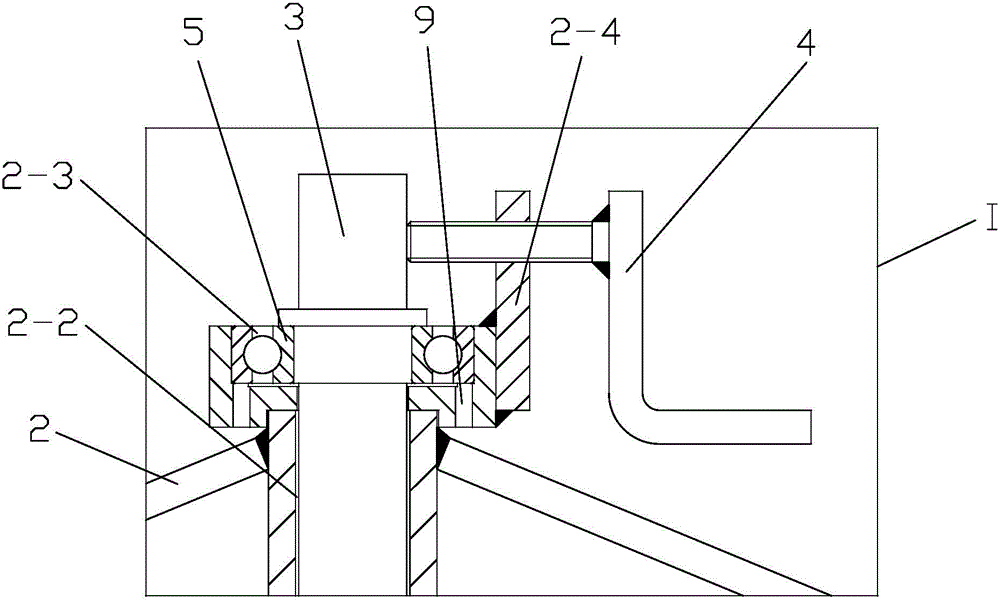

[0028] like Figure 1 to Figure 4 As shown, the present invention comprises a base 1, a swivel frame 2, a shaft 3 and a handle 4, the swivel frame 2 is arranged above the base 1, and the top of the swivel frame 2 is fixed with a plurality of retaining rods 2-1, and a plurality of A wire retaining rod 2-1 forms a wire coil placement column for placing wire coils, the base 1 is provided with a first hole 1-1 along the central axis, and the rotating frame 2 is provided with a second hole along the central axis 2-2, the upper end surface of the base 1 has a first groove 1-2, the lower end surface of the rotating frame 2 has a third groove 2-5, and the base 1 and the rotating frame 2 are provided There is a second bearing 6, the outer ring of the second bearing 6 is tightly fitted with the first groove 1-2, the inner ring of the second bearing 6 is tightly fitted with the third groove 2-5, and the rotating frame The upper end surface of 2 has a second groove 2-3, and the first bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com