Surface treatment method for nylon material

A surface treatment, nylon technology, applied in the direction of coating, etc., can solve the problems of low adhesion, easy cracking, etc., and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Please refer to the drawings in the accompanying drawings, wherein like reference numerals refer to like components. The following description is based on illustrated specific embodiments of the invention, which should not be construed as limiting other specific embodiments of the invention not described in detail herein.

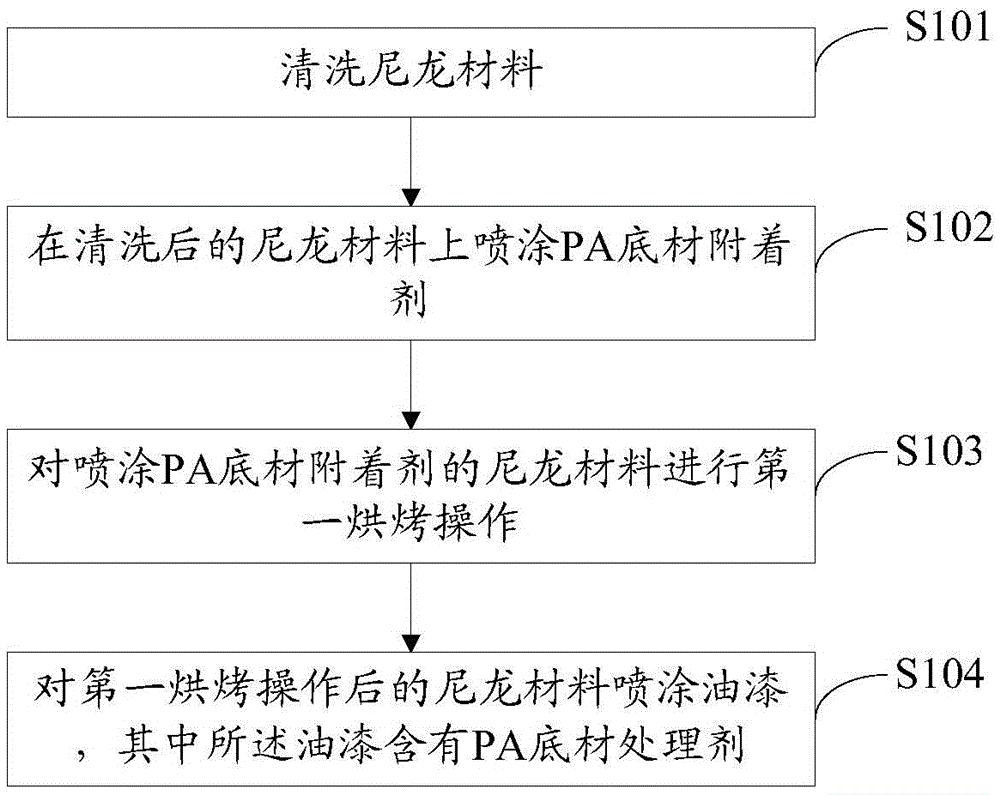

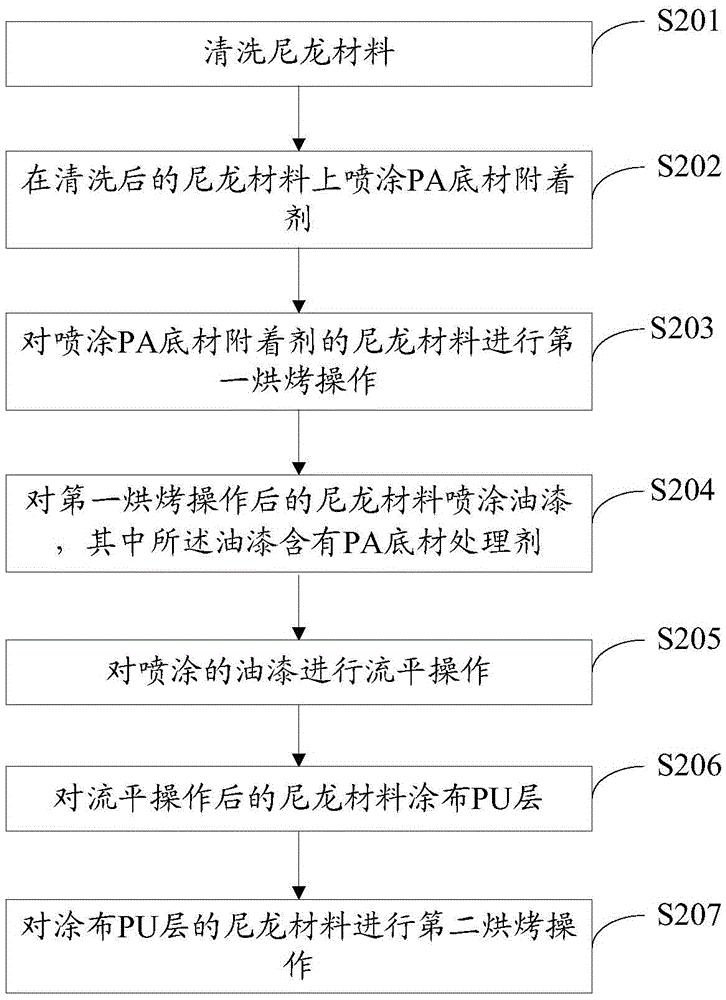

[0024] Please refer to figure 1 , figure 1 It is a flowchart of the first preferred embodiment of the surface treatment method of nylon material of the present invention. The surface treatment method of the nylon material of this preferred embodiment comprises:

[0025] Step S101, cleaning the nylon material;

[0026] Step S102, spraying PA substrate adhesive on the cleaned nylon material;

[0027] Step S103, performing a first baking operation on the nylon material sprayed with the PA substrate adhesion agent;

[0028] Step S104, spray paint on the nylon material after the first baking operation, wherein the paint contains a PA substrate treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com