A kind of anhydrous calcium sulfate whisker surface modification method

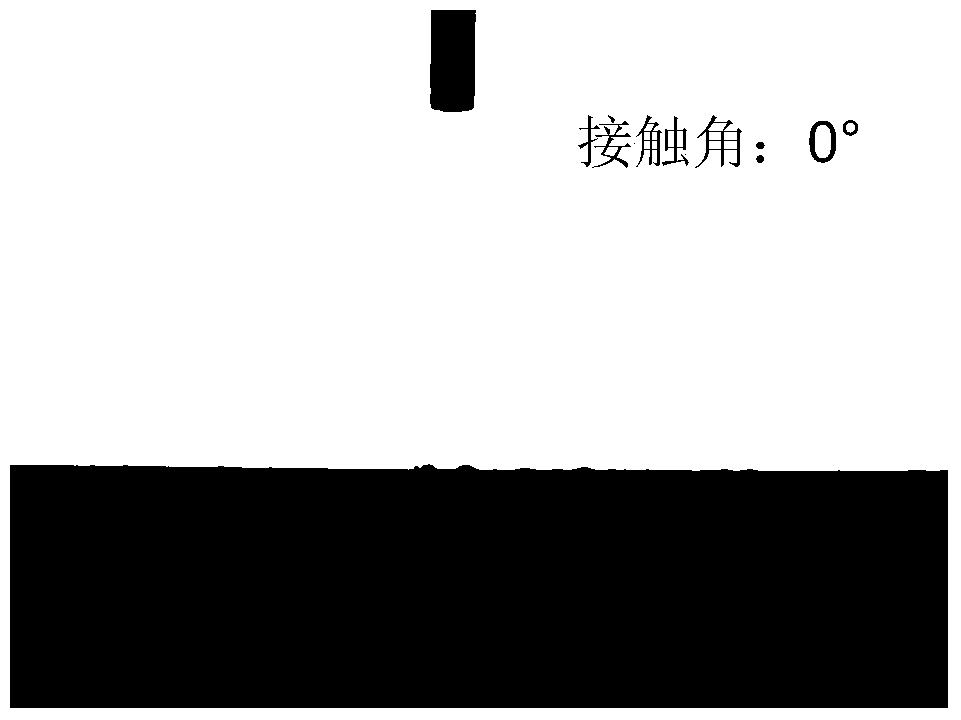

An anhydrous calcium sulfate, surface modification technology, applied in the field of crystal preparation, can solve the problems of low surface activity of whiskers, difficult direct action of organic modifiers, etc., and achieve the effect of increasing the surface activity of whiskers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

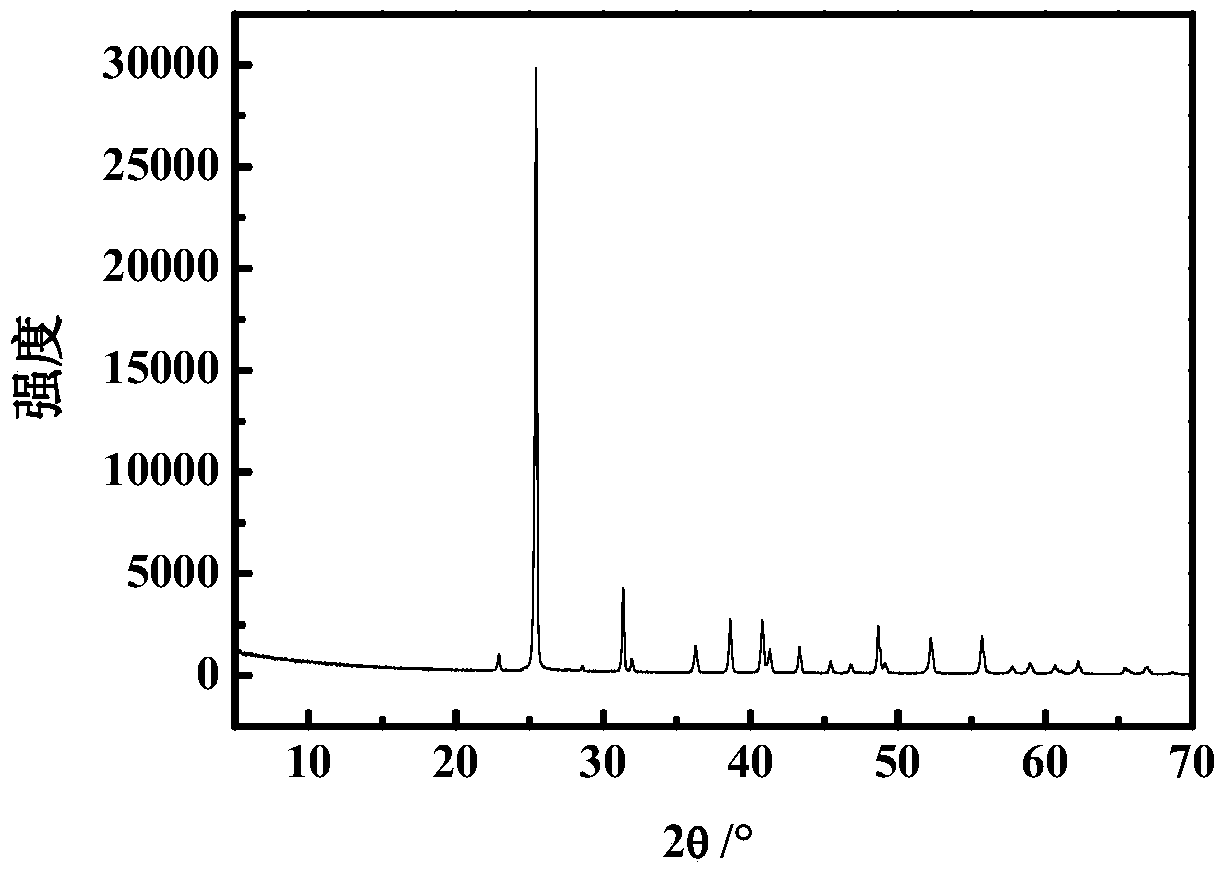

[0027] Below, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0028] The invention provides a method for surface modification of anhydrous calcium sulfate whiskers, comprising the steps of:

[0029] Step 1: Anhydrous calcium sulfate whiskers and inorganic salt solution are mixed and stirred according to the mass-volume ratio of 1:20-50 for 10-30 minutes, and the first filtrate and the first filter cake are obtained after solid-liquid separation. Wherein, the inorganic salt solution includes any one of phosphate and silicate aqueous solutions. The concentration of substances in the inorganic salt solution is controlled to be 0.015mol / L-0.1mol / L.

[0030] Step 2: Add stearic acid and absolute ethanol to the first filter cake; mix and heat to 20°C to 90°C to form a slurry; the amount of stearic acid is the same as the anhydrous calcium sulfate whisker 6%-15% of the mass; the mass-volume ratio of the anhydrous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com