A kind of high-strength and high-plasticity medium manganese Q&P steel cold-rolled annealed plate and its preparation process

A cold-rolled annealing and high plasticity technology, which is applied in the field of automobile sheets and home appliance sheets, can solve the problems that the residual austenite structure is not much, and the strength and performance cannot be significantly improved, so as to increase the content of retained austenite and take into account the The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

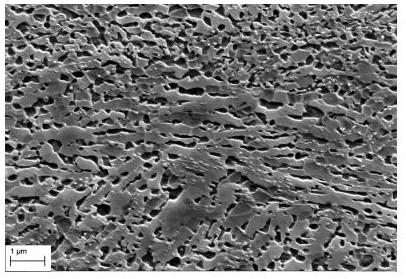

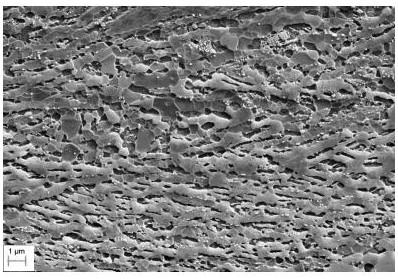

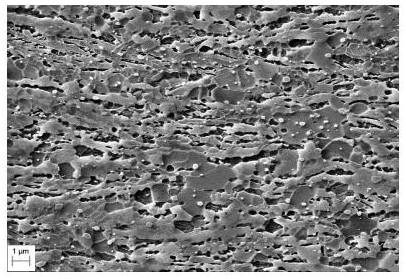

Image

Examples

Embodiment Construction

[0021] A high-strength and high-plasticity medium manganese Q&P steel cold-rolled annealed plate of the present invention, its chemical composition and weight percentage are respectively: C 0.1~0.3%, Si 0.8~2.0%, Mn 4.0~8.0%, P≤0.01 %, S ≤ 0.01%, N ≤ 0.01%; wherein C is preferably 0.12~0.22%, Si is preferably 1.2~1.8%, Mn is preferably 5.0~7.0%, and Nb or V or Ti, the rest is iron and unavoidable impurities.

[0022]The preparation method of the high-strength and high-plasticity medium manganese Q&P steel cold-rolled annealed plate of the present invention includes smelting, casting, hot rolling, cold rolling and heat treatment processes, and the chemical composition and weight percentage of the annealed plate are: C 0.1~0.3% , Si 0.8~2.0%, Mn4.0~8.0%, P≤0.01%, S ≤ 0.01%, N ≤ 0.01%, the rest is iron and unavoidable impurities; the hot rolling process requires the billet to be heated to 1150~1250℃ Insulate for 1 to 2 hours, then carry out rough rolling and finish rolling in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com