1000 MPa-grade high-strength and high-plasticity hot-rolled steel plate and manufacturing method thereof

A hot-rolled steel sheet and high-strength technology, which is applied to 1000MPa-grade high-strength and high-plastic hot-rolled steel sheet and its manufacturing field, can solve the problems of high industrial production cost, difficult smelting, poor processing performance, etc., and achieve the effect of reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The chemical composition of the high-strength high-plasticity steel in the examples is shown in Table 1.

[0028] Table 1 Chemical Composition (wt.%)

[0029]

[0030] Its manufacturing method is carried out according to the following steps:

[0031] (1) Smelt molten steel in a pressurized induction furnace according to the ingredients and ingredients in Table 1, vacuumize and make the molten steel temperature reach 1600°C;

[0032] When the pressure in the furnace is lower than 5 Pa, nitrogen with a purity of 99.9993% is charged to make the nitrogen pressure in the furnace reach 2 atmospheres. Before casting, raise the nitrogen pressure in the furnace to 5 atmospheres, and keep the pressure for 30 minutes after casting to obtain ingots;

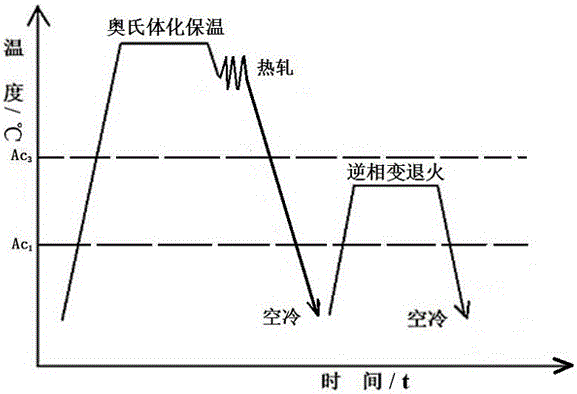

[0033] (2) Heating the cast ingot to 1200°C with the furnace and keeping it warm for 1 hour, followed by 8 passes of hot rolling, the starting and finishing temperatures were 1160°C and 860°C respectively, and cooled to room temp...

Embodiment 2

[0036] The chemical composition of the advanced high-strength steel in this example is shown in Table 2.

[0037] Table 2 Chemical Composition (wt.%)

[0038]

[0039] Its manufacturing method is carried out according to the following steps:

[0040] (1) Smelt molten steel in a pressurized induction furnace according to the ingredients and ingredients in Table 2, vacuumize and make the temperature of molten steel reach 1580°C;

[0041] When the pressure in the furnace is lower than 5 Pa, nitrogen with a purity of 99.9993% is charged to make the nitrogen pressure in the furnace reach 3 atmospheres. Before casting, the nitrogen pressure in the furnace needs to be increased to 4 atmospheres, and after the casting is completed, the pressure needs to be maintained for 35 minutes to obtain ingots;

[0042](2) Heat the cast ingot to 1200°C with the furnace and hold it for 2 hours, then go through 7 passes of hot rolling, the starting temperature and final rolling temperature are...

Embodiment 3

[0045] The chemical composition of the high-strength high-plasticity steel in the examples is shown in Table 3.

[0046] Table 3 Chemical Composition (wt.%)

[0047]

[0048] Its manufacturing method is carried out according to the following steps:

[0049] (1) Smelt molten steel in a pressurized induction furnace according to the ingredients and ingredients in Table 3, vacuumize and make the molten steel temperature reach 1550°C;

[0050] When the pressure in the furnace is lower than 5Pa, fill nitrogen with a purity of 99.9993%, so that the nitrogen pressure in the furnace reaches 2 atmospheres. Before casting, the nitrogen pressure in the furnace needs to be raised to 6 atmospheres. Press for 40 minutes to obtain an ingot;

[0051] (2) Heating the cast ingot to 1150°C with the furnace and holding it for 2 hours, then after 9 passes of hot rolling, the starting and finishing temperatures were 1100°C and 810°C, respectively, and cooled to room temperature in the air afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com