A crash-resistant hot-formed martensitic steel favoring optimization of retained austenite

A retained austenite and martensitic steel technology, applied in the field of alloy steel, can solve the problems of deteriorating the surface coating performance of hot-formed steel sheets, easily producing oxide scale on the surface, reducing the quality of the coating, and optimizing the shape of retained austenite. The effect of the distribution, the operation is feasible, and the process flow is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

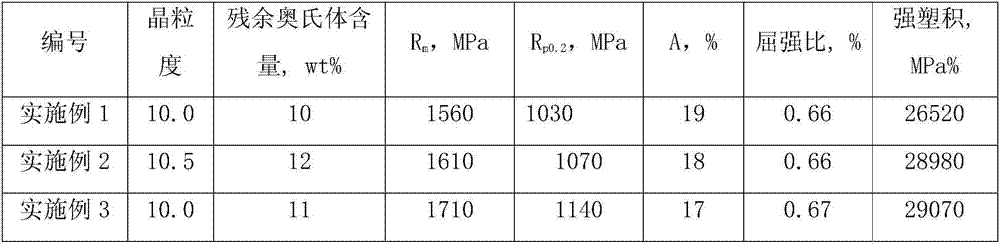

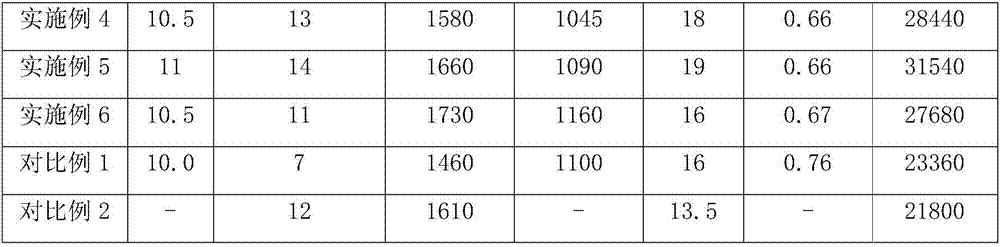

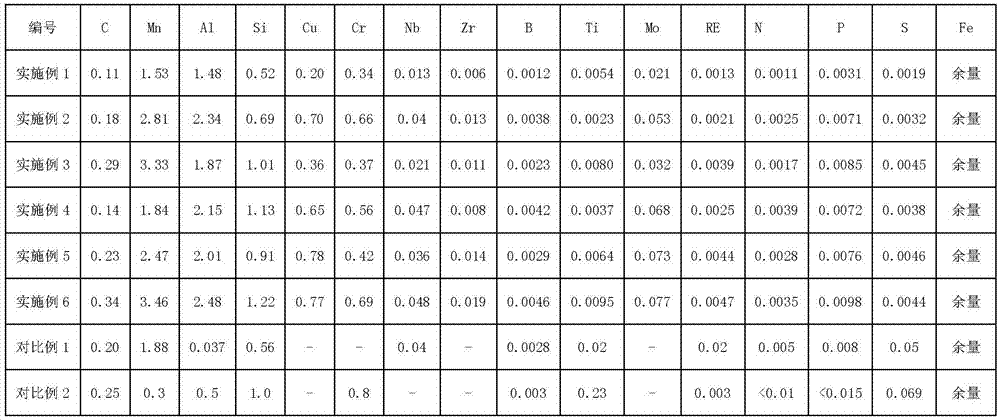

[0039] According to the chemical composition range designed by the present invention, 6 heats of molten steel were smelted on a 500Kg induction furnace, and were continuously cast into billets. 2mm thin plate, then heat the thin plate to 900-950°C for 5 minutes for austenitization, quickly take it out and place it under a temperature-controllable mold for thermoforming process, obtain a U-shaped part, and generate 6 examples in total steel body. The composition (as table 1) and performance (as table 2) of these 6 embodiments and two comparative examples are compared, two comparative examples are respectively the martensitic steel disclosed by invention patent CN101275200A, CN102766818A, its specific chemical composition As shown in Table 1, the parts after the thermoforming process were sampled, and the tensile mechanical properties were tested according to the national standard, and the results are shown in Table 2. It can be seen that the tensile strength of parts prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com