Novel pavement slab

A road slab and a new type of technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of large rotational freedom of the connecting unit, affect the traffic effect of vehicles, and uneven ballast distribution on the ground, so as to improve traffic capacity and enhance anti-skid The effect of anti-wear ability and enhanced load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

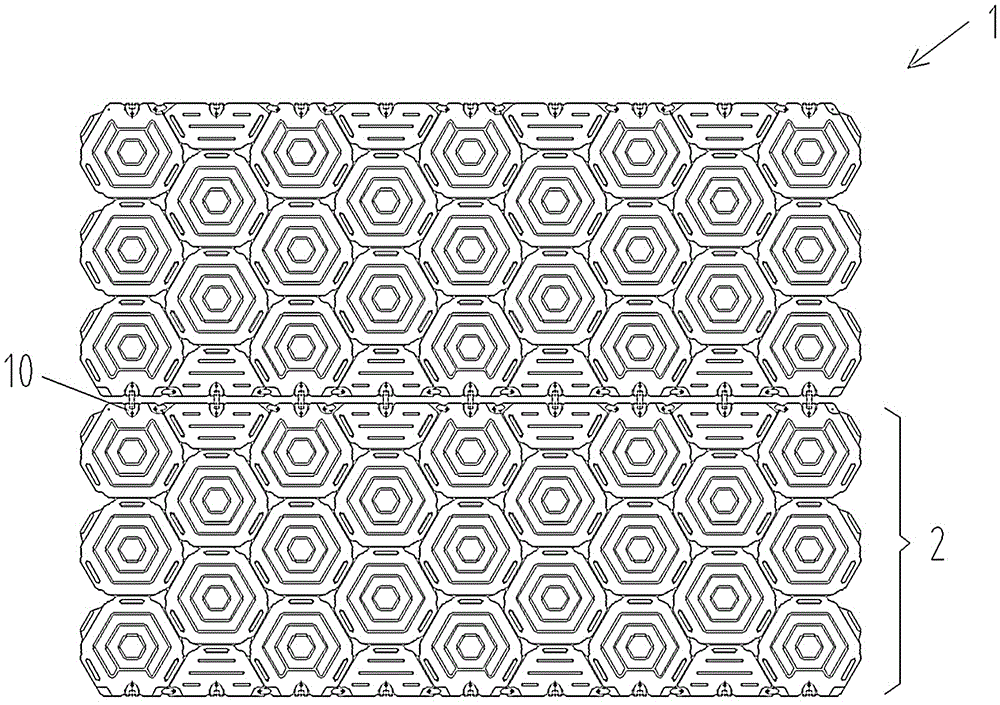

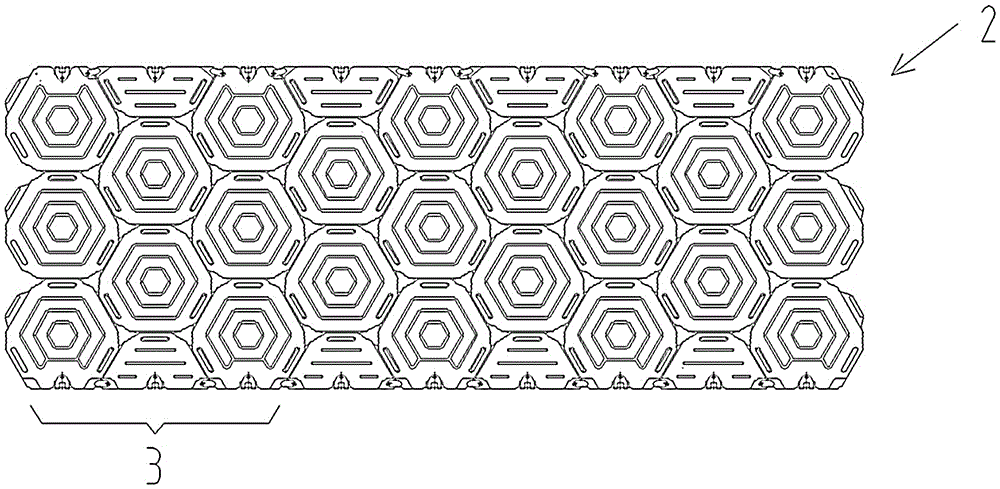

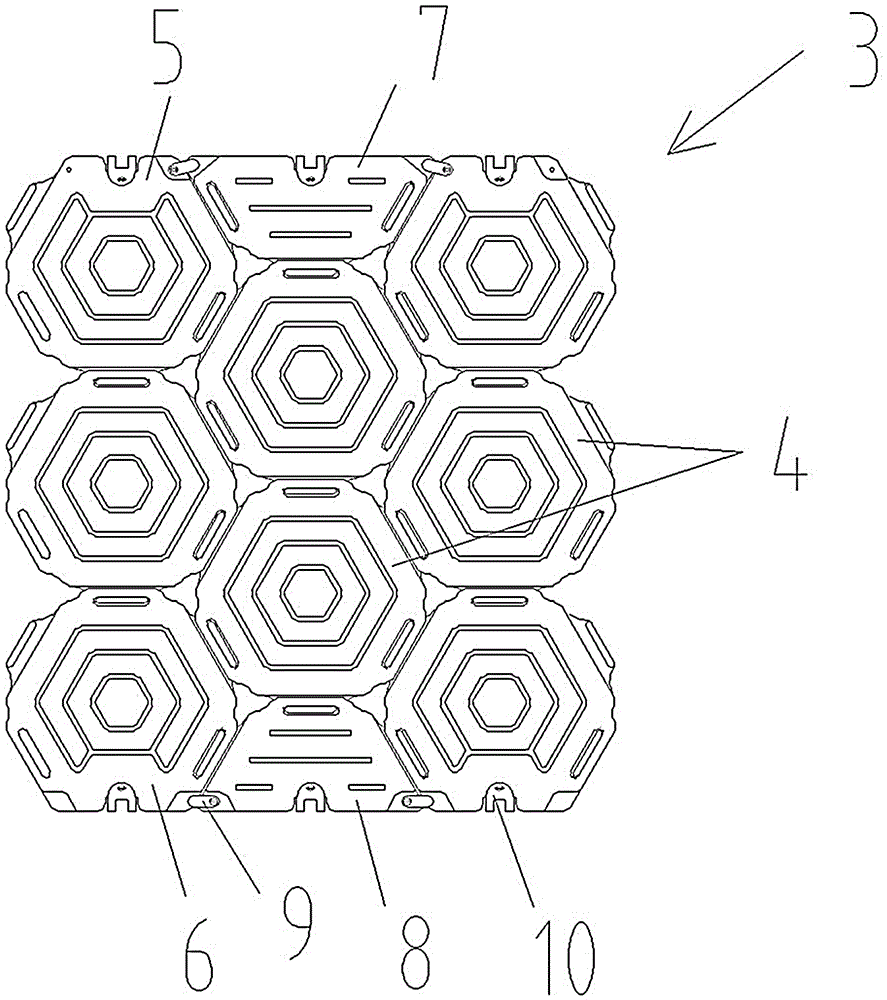

[0032] combine Figure 1~3 As shown, the present invention provides a novel road slab, the road slab 1 includes a group of sub-road panels 2 hinged in turn, and each sub-road panel 2 includes a group of basic pavement units 3 that are spliced together, and the basic pavement unit 3 consists of ten pavement blocks Splicing to form a rectangle; the basic pavement unit 3 composed of ten pavement blocks includes four middle pavement blocks 4, two upper pavement blocks 5, two lower pavement blocks 6, one upper pavement block 7 and one lower pavement block 7, four The middle pavement block 4 is spliced in the middle and is cross-shaped.

[0033] combine Figure 5 and Image 6 As shown, the middle pavement block 4 is hexagonal, and the middle pavement block 4 is provided with three first male buckles 4a and three first female grooves 4b, and the first male buckles 4a and the first female grooves 4b are alternately distributed in the middle On the six sides of the road surface ...

Embodiment 2

[0041] combine Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the basic road surface unit 3 is composed of seven road surface blocks, and the basic road surface unit 3 includes a middle road surface block 4, two upper end road surface blocks 5, two lower end The pavement block 6, an upper pavement block 7 and a lower pavement block 8; the structure and connection method of each pavement block are the same as those in the first embodiment.

[0042] In the present invention, hexagonal and trapezoidal pavement blocks are clamped to each other to form a rectangular basic pavement unit, and then a number of basic pavement units are interconnected to form a sub-pavement panel, and finally several sub-pavement panels are hinged to form a pavement panel; the basic pavement unit is honeycomb Shaped structure, high stability, limits the degree of freedom between the various pavement blocks, strengthens the rigid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com