Sliding stainless steel cover plate device and actuation method thereof

A cover device and sliding cover technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of easy aging, poor waterproof effect at joints, and difficult implementation, so as to prolong the service life and facilitate Easy to open and great results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

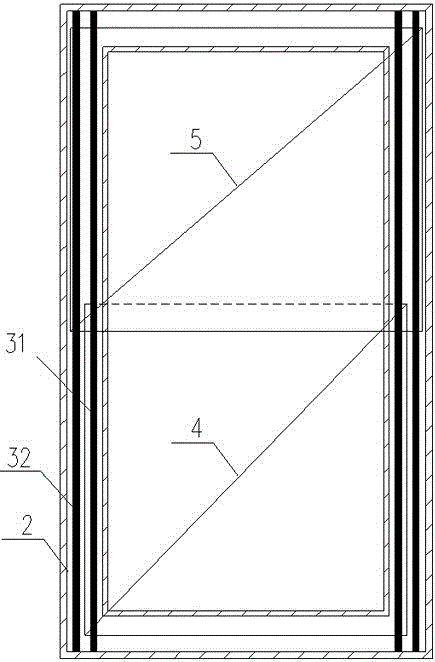

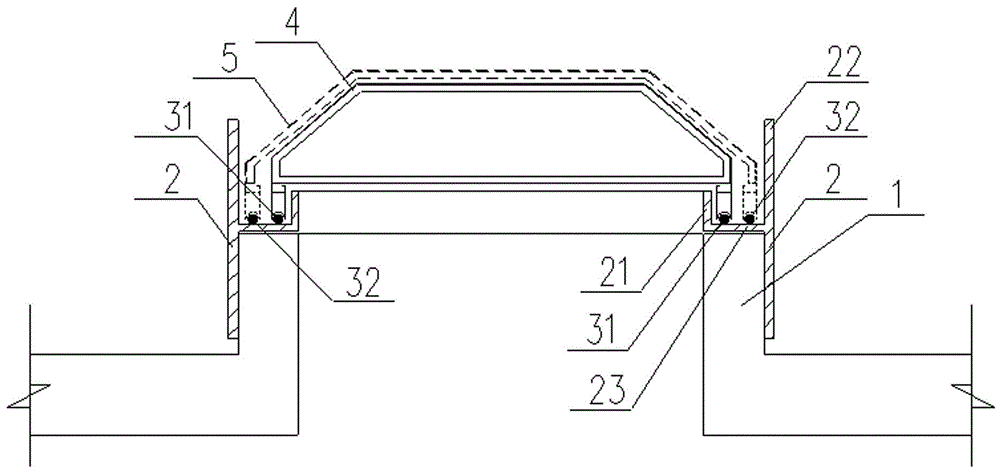

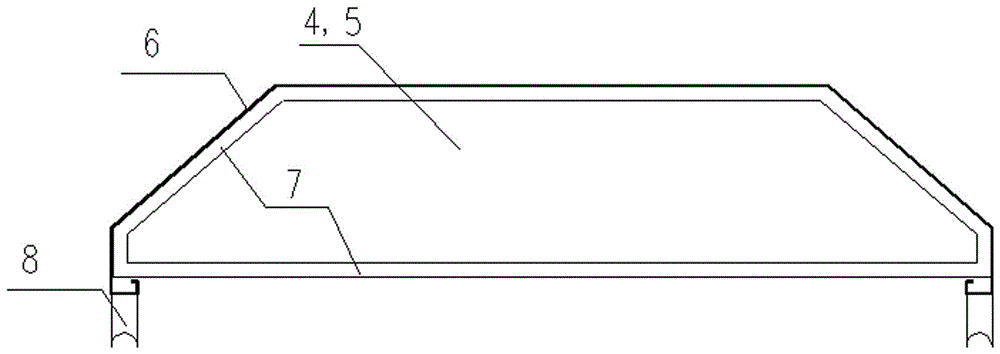

[0024] The following combination Figure 1 ~ Figure 3 , the present invention will be further elaborated by specifying a preferred specific embodiment.

[0025] Such as figure 1 and figure 2 As shown, the slidable stainless steel cover plate device provided by the present invention is arranged above the openings of various feeding ports or maintenance manholes of comprehensive pipe galleries, pools, and pump room buildings (structures), including: the side of the opening Beam 1, which was implemented in advance, is vertically arranged around the opening of the hole; stainless steel water stop baffles 2 are respectively fixed on the side beams 1 of each hole; sliding components are respectively fixed on a pair of oppositely arranged stainless steel On the water stop baffle 2; the cover plate assembly is arranged above the hole, is connected with the sliding assembly, and can move along the sliding assembly.

[0026] The bottom end of the hole side beam 1 is flush with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com