Locking device used for electronic-control-free well lid lock and having stable gear maintaining function

A locking device and manhole cover technology, applied in non-mechanical transmission-operated locks, construction locks, construction and other directions, can solve the problems of short lock life, high cost, failure, etc., and achieve the effect of avoiding unmaintainable and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

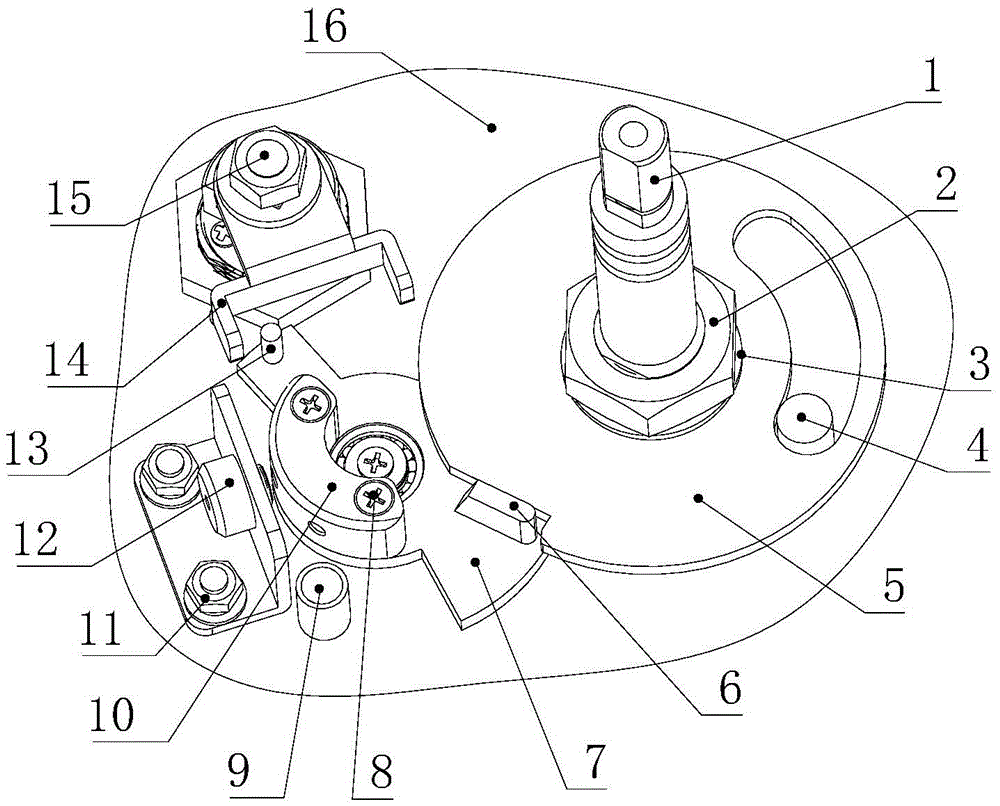

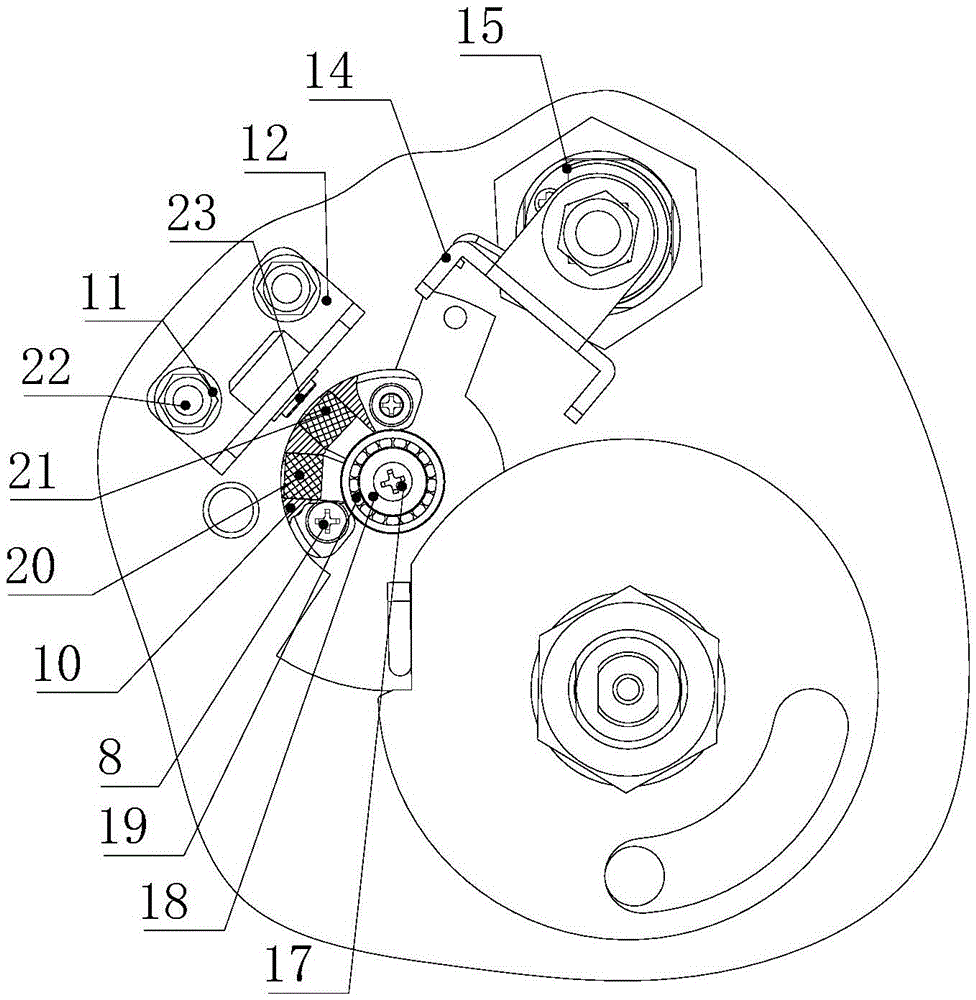

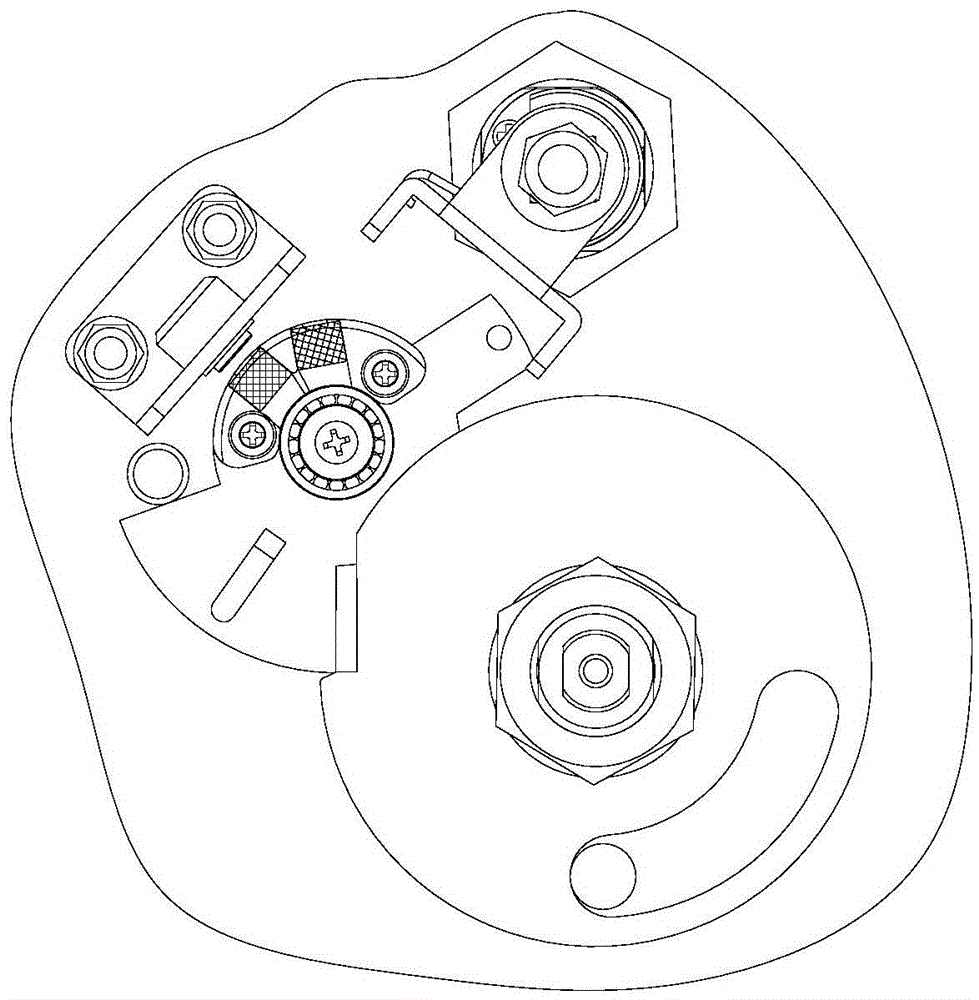

[0027] The locking device applied to the manhole cover lock without electric control to stably maintain the gear position includes a lock case 16, a main shaft 1 is arranged on the lock case 16, the top of the main shaft 1 is connected with the manhole cover, and the bottom end of the main shaft 1 is movable with a locking device. Disc 5, between chuck 5 and lock housing 16 is provided with the stopper mechanism that is used to stop chuck 5 rotations after chuck 5 rotates setting angle, is provided with chuck connecting rod 7 movablely on lock housing 16, clamps One end of the disc connecting rod 7 is provided with a top block 6 for stopping the rotation of the chuck 5, and the other end of the chuck connecting rod 7 is provided with a stop pin 13 for driving the rotation of the chuck connecting rod 7. There are two first magnets (magnet A20 and magnet B21) at a set distance, and a second magnet (magnet C23) is arranged on the lock housing 16. After the chuck connecting rod 7 r...

Embodiment 2

[0039] The locking device applied to the manhole cover lock without electric control to stably maintain the gear position includes a lock case 16, a main shaft 1 is arranged on the lock case 16, the top of the main shaft 1 is connected with the manhole cover, and the bottom end of the main shaft 1 is movable with a locking device. Disc 5, between chuck 5 and lock housing 16 is provided with the stopper mechanism that is used to stop chuck 5 rotations after chuck 5 rotates setting angle, is provided with chuck connecting rod 7 movablely on lock housing 16, clamps One end of the disc connecting rod 7 is provided with a top block 6 for stopping the rotation of the chuck 5, and the other end of the chuck connecting rod 7 is provided with a stop pin 13 for driving the rotation of the chuck connecting rod 7. There are two first magnets (magnet A20 and magnet B21) at a set distance, and a second magnet (magnet C23) is arranged on the lock housing 16. After the chuck connecting rod 7 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com