Wind volume and wind pressure sensing and pressure receiving device

A receiver and wind pressure technology, which is applied in the field of air volume and pressure sensing and pressure receivers, can solve the problems of low reading accuracy, affecting airflow reading accuracy, failing to achieve energy saving and precise control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

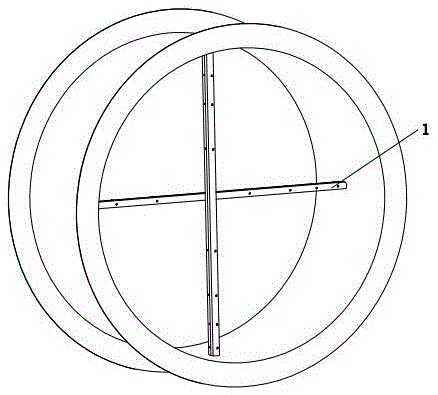

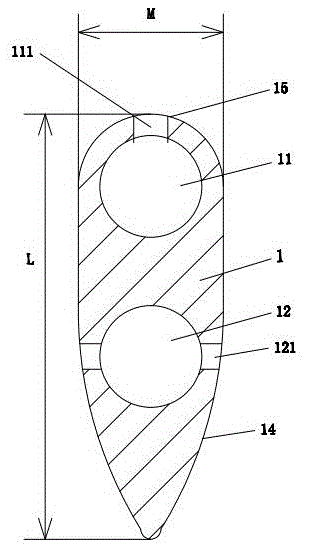

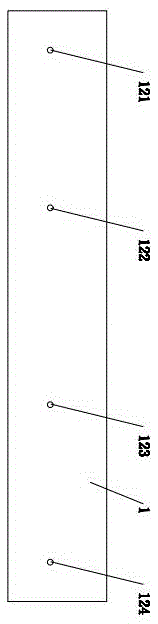

[0035] Such as Figure 1 to Figure 4As shown, it is an air volume and pressure sensing and pressure receiver, including two air volume and pressure sensing rods 1 installed on the air duct; the length of the air volume and wind pressure sensing rod 1 is 150 ± 0.2 mm, The cross-section of the wind pressure sensing rod 1 is in the shape of an airfoil, and the length L and width M of the cross-section of the wind pressure sensing rod 1 are 25 ± 0.2 mm and 8.5 ± 0.2 mm respectively; the top surface of the wind pressure sensing rod 1 is the windward side 15 , the windward surface 15 is arc-shaped, and its radius is 4.25 ± 0.2 mm; the left and right sides of the lower part of the air volume and pressure sensing rod 1 are inclined inwardly in an arc shape to form a wind-guiding surface 14, and the radius of the wind-guiding surface 14 is 24.7 ± 0.2 mm; in the air volume wind pressure sensing rod 1, there are windward induction flow channel 11 and wind guide induction flow channel 12,...

Embodiment 2

[0038] like figure 1 , figure 2 , Figure 5 and Image 6 As shown, it is a kind of air volume and wind pressure sensing and pressure receiver, including more than one air volume and wind pressure sensing rod 1 installed at the air duct; the length of the air volume and wind pressure sensing rod 1 is 180±0.2 mm, The section of the pressure sensing rod 1 is in the shape of an airfoil, and the length L and width M of the section of the air volume and wind pressure sensing rod 1 are respectively 25 ± 0.2 mm and 8.5 ± 0.2 mm; the top surface of the air volume and wind pressure sensing rod 1 is the windward side 15, The windward surface 15 is arc-shaped, and its radius is 4.25 ± 0.2 millimeters; the left and right sides of the lower part of the air volume and wind pressure sensing rod 1 are inclined inward in an arc shape to form a wind-guiding surface 14, and the radius of the wind-guiding surface 14 is 24.7±0.2 mm; windward induction flow channel 11 and wind guide induction fl...

Embodiment 3

[0041] like figure 1 , figure 2 , Figure 7 and Figure 8 As shown, it is an air volume and pressure sensing and pressure receiver, including more than one air volume and pressure sensing rod 1 installed at the air duct; the length of the air volume and wind pressure sensing rod 1 is 200 ± 0.2 mm, The section of the pressure sensing rod 1 is in the shape of an airfoil, and the length L and width M of the section of the air volume and wind pressure sensing rod 1 are respectively 25 ± 0.2 mm and 8.5 ± 0.2 mm; the top surface of the air volume and wind pressure sensing rod 1 is the windward side 15, The windward surface 15 is arc-shaped, and its radius is 4.25 ± 0.2 millimeters; the left and right sides of the lower part of the air volume and wind pressure sensing rod 1 are inclined inward in an arc shape to form a wind-guiding surface 14, and the radius of the wind-guiding surface 14 is 24.7±0.2 mm; windward induction flow channel 11 and wind guide induction flow channel 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com