Bi-directional intelligent search-based manufacturing enterprise shop scheduling optimization method

A technology of intelligent search and workshop scheduling, applied in the direction of control/adjustment system, program control, comprehensive factory control, etc., can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The present embodiment (as shown in Table 1) carries out two-way intelligent search in combination with the workshop scheduling of the manufacturing enterprise, and the steps are as follows:

[0090]

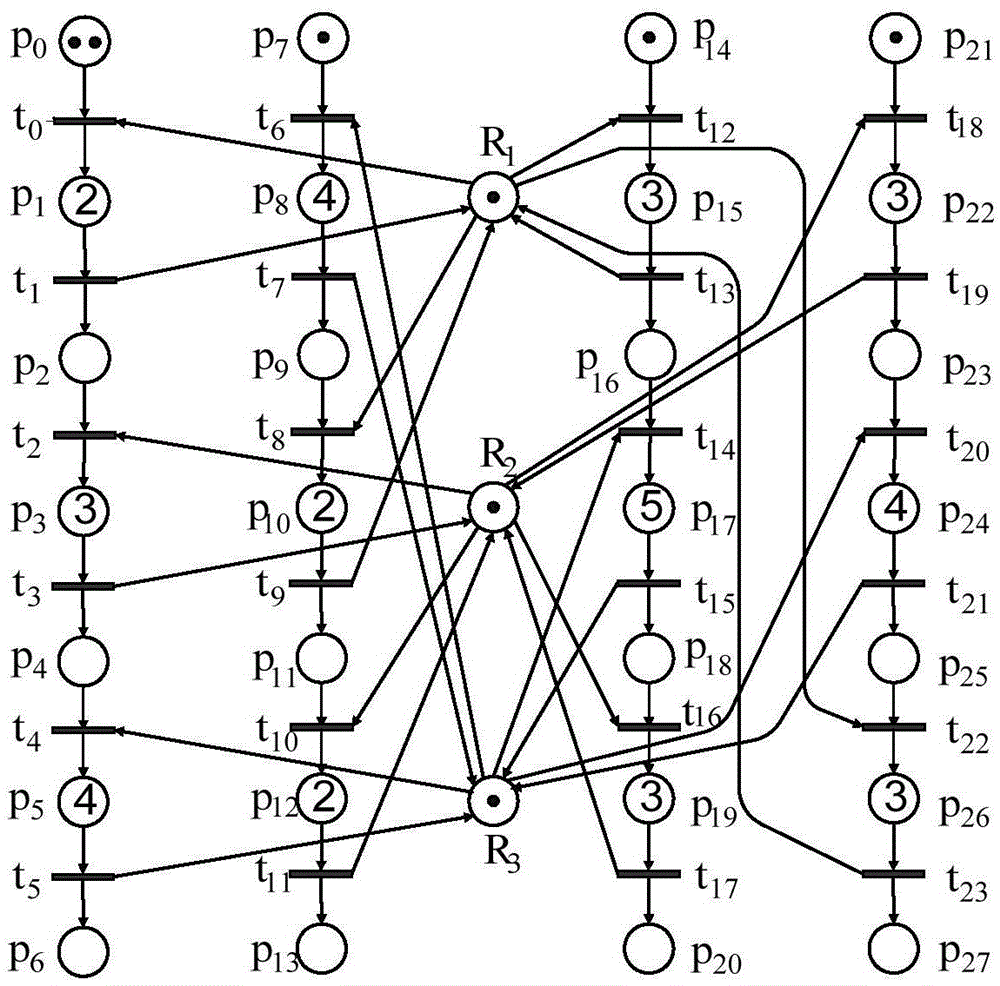

[0091] 1), the Petri net model constructed by the top-down method is as follows figure 1 Shown:

[0092] 2), according to the model Petri net generation program input file is as follows:

[0093] 12,0,3,2,1,1,1;

[0094] 1,1,1,1,2; 1,2,2,2,3; 1,3,3,3,4;

[0095] 2,1,4,3,4; 2,2,5,1,2; 2,3,6,2,2;

[0096] 3,1,7,1,3; 3,2,8,3,5; 3,3,9,2,3;

[0097] 4,1,10,2,3; 4,2,11,3,4; 4,3,12,1,3;

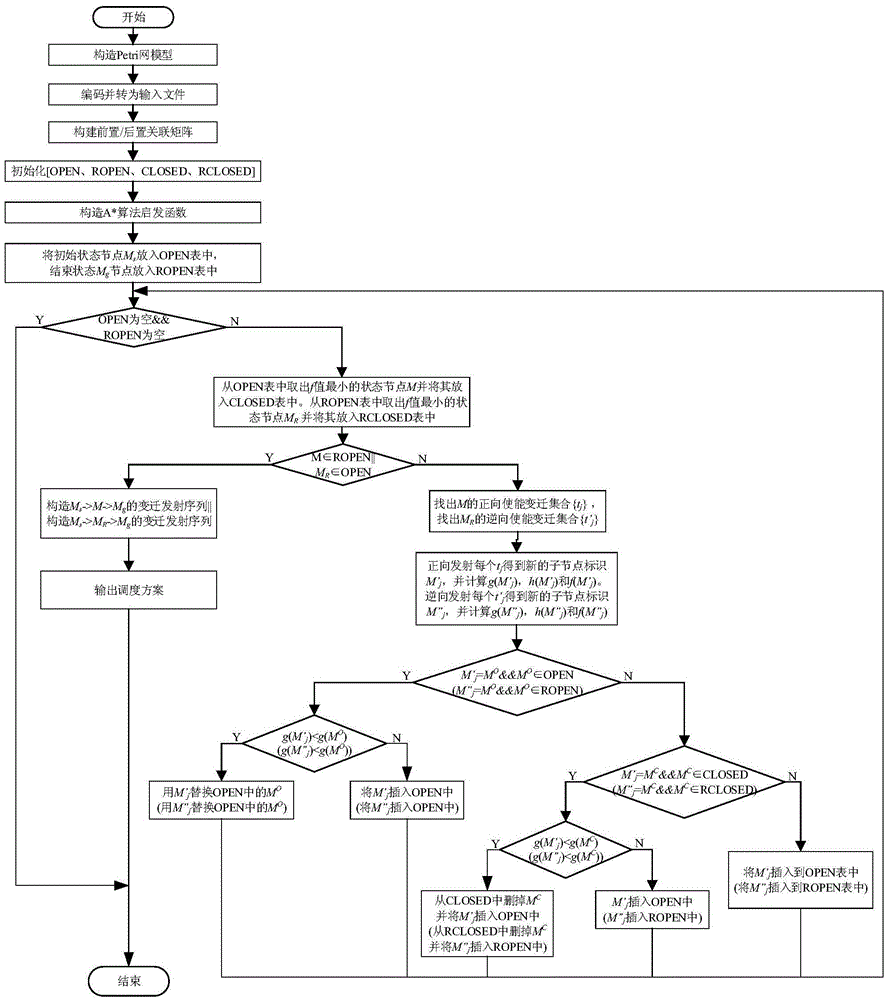

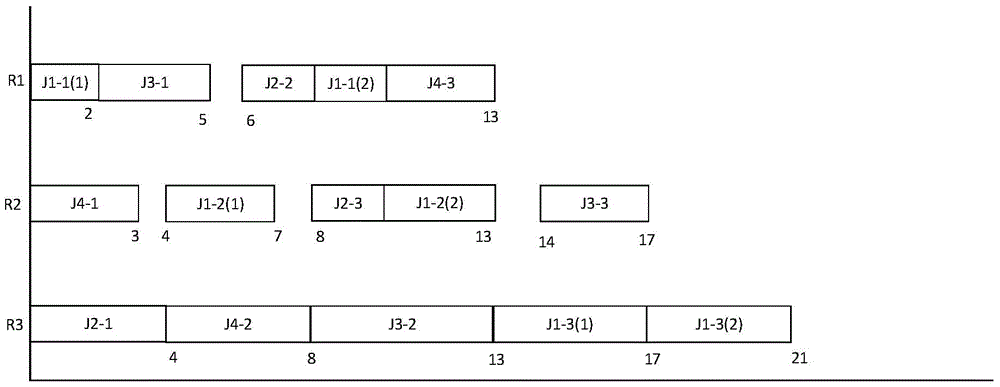

[0098] 3) Input the input file into the two-way A* scheduler. First, the program constructs the correlation matrix of the model according to the input, and then the program uses the heuristic function h that can be adopted, according to figure 2 The flow of the system runs the A* algorithm separately from the system start state identification and end state identification. If the algor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com