F-type rolling mill calibrating tool for hot continuous rolling production line

A rolling production line and rolling mill technology, applied in the field of calibration tools for F-type rolling mills in hot continuous rolling production lines, can solve problems such as inconsistent spacing L1, low copper bar usage, and potential safety hazards, and achieve improved accuracy and safety , Eliminate the effect of personal safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

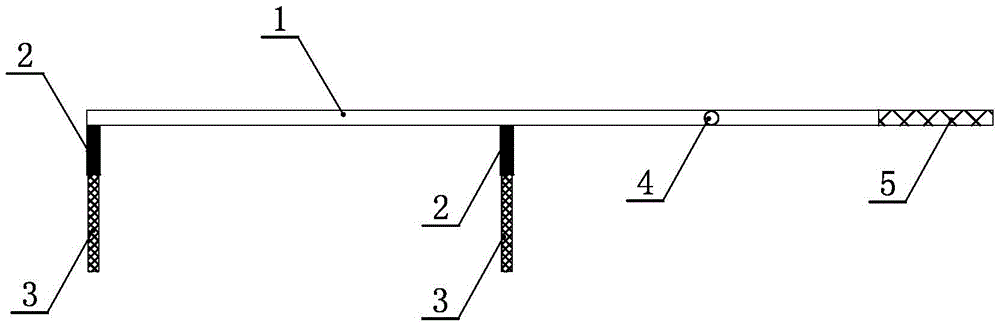

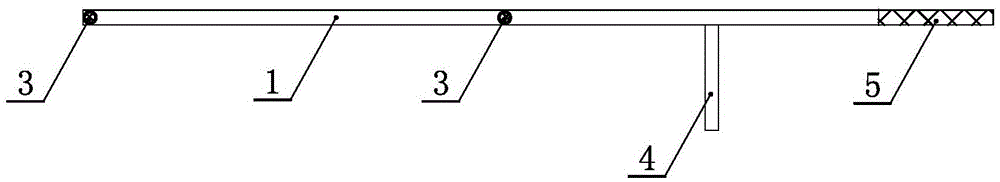

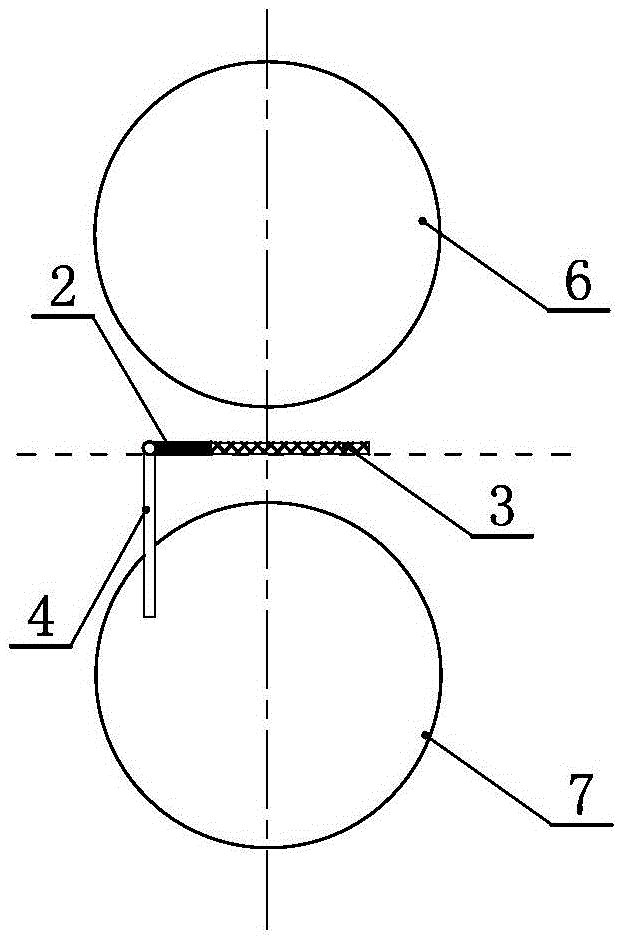

[0022] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0023] Such as Figure 1-4 As shown, the invention includes a support rod 1, a sleeve 2, a positioning rod 4 and a copper rod 3. The support rod is a slender rod, and two sleeves are fixed on the support rod. The two sleeves are equal in length and diameter, and the two sleeves are arranged in parallel.

[0024] The interval between the sleeves is L1, one end of the sleeve is vertically fixed on the support rod, the other end of the sleeve is open, and the copper rods are plugged in the open ends of the two sleeves, and the ends of the copper rods are exposed The sleeve is at a certain distance. The length and diameter of the two copper rods are also the same, and the distance between the two copper rods i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com