Workpiece of air condition compressor

A technology for air-conditioning compressors and workpieces, which is applied to liquid variable-capacity machinery, pump components, mechanical equipment, etc., can solve the problems of insufficient outer surface flatness and rough processing, and achieve good outer surface flatness, high processing efficiency, and high processing efficiency. Good assembly performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

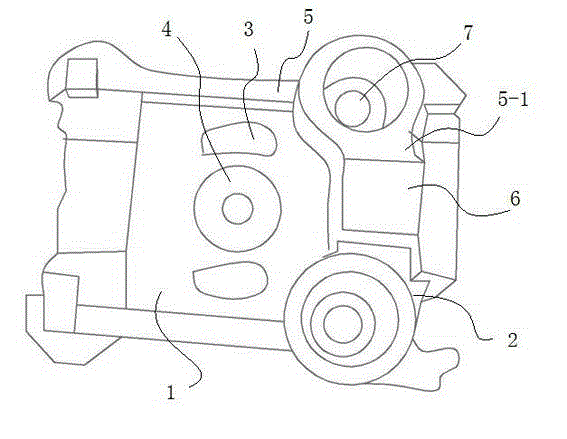

[0010] Such as figure 1 Shown, a kind of workpiece of air conditioner compressor, it comprises mold base 1, and described mold base 1 upper end is provided with at least two convex parts 2, and described convex part 2 is provided with U-shaped groove 3, and described U-shaped A through column 4 extends in the groove 3, and one end of the mold base 1 is provided with a protruding part 5, the protruding part 5 is 0.1-0.3 cm higher than the horizontal plane of the mold base 1, and the protruding part 5 is connected with the convex part 2, The distance between the mold bases 1 is 2-4 cm, and the convex part 2 is integrally formed with the mold bases 1 .

[0011] A rectangular opening 6 is provided in the middle of the mold base 1 , and a circular protrusion 5 - 1 is provided between the openings 6 .

[0012] The height of the convex part 2 is higher than that of the protruding part 5 , and the lower end of the protruding part 5 is provided with a mounting hole 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com