Quick-changing submerged nozzle and steel shell installation device and method

An installation device, immersion technology, applied in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of easy contamination or damage, irreparable, time-consuming and labor-intensive, to avoid contamination and damage, Reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

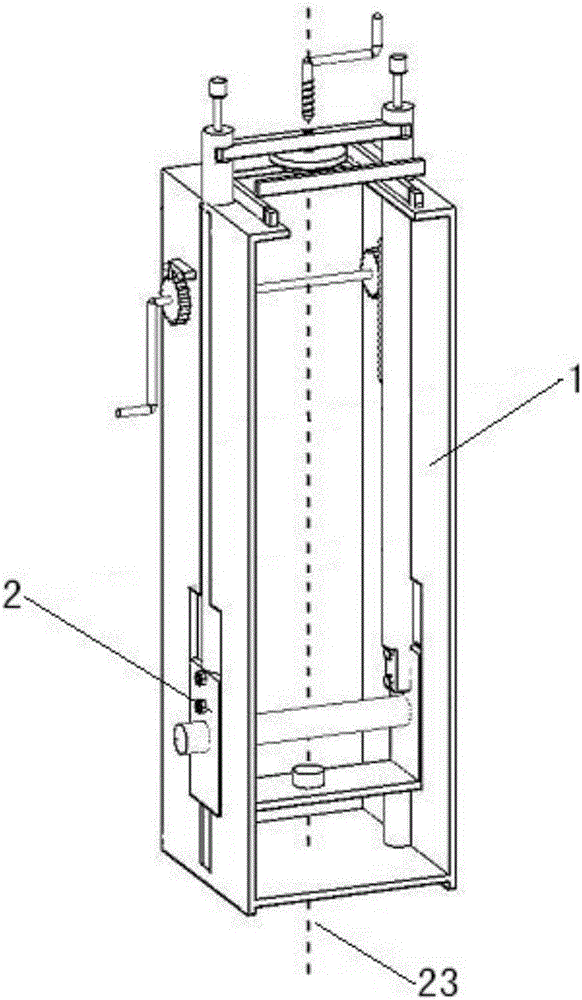

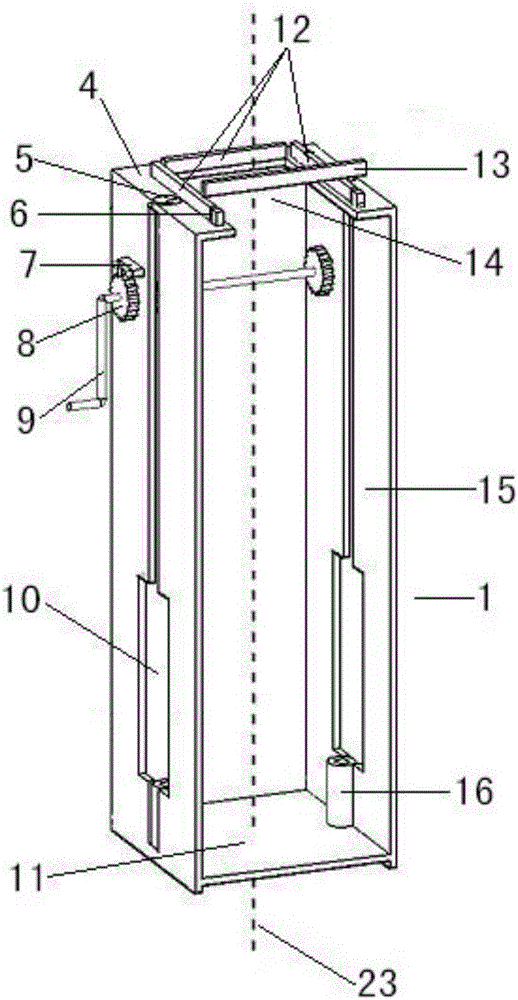

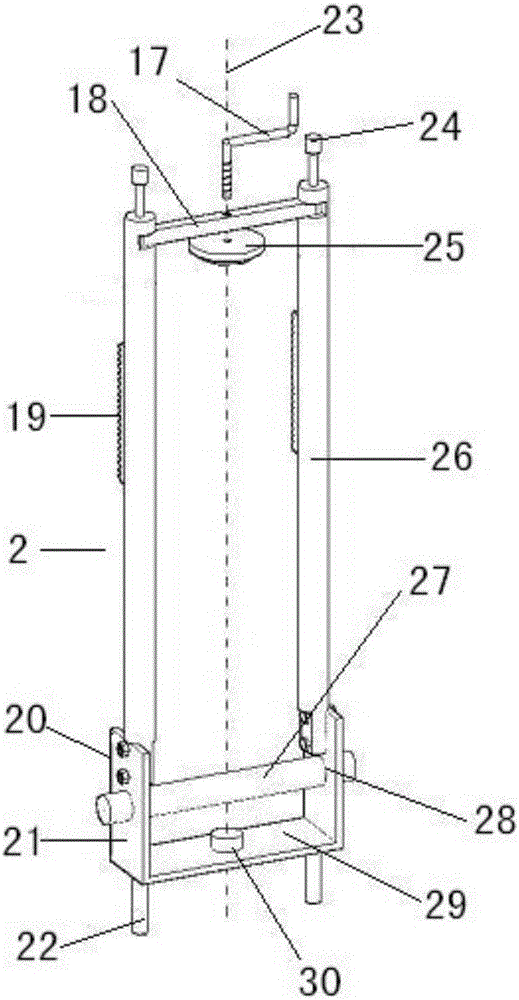

[0031] See Figure 1-Figure 6 , the installation device of the steel shell of the quick-change submerged nozzle is composed of two parts, the support frame 1 and the positioning frame 2. The positioning frame 2 is assembled in the support frame 1, and is used to fix the quick-change submerged nozzle 3, so that the quick-change submerged nozzle The vertical axis 36 of the steel channel of the nozzle 3 is perpendicular to the bottom plane of the steel shell, so that the horizontal line 40 in the center of the outlet hole 35 of the quick-change submerged nozzle is parallel to the two opposite sides of the steel shell 34, and the positioning frame 2 can carry the quick-change immersion Type nozzle 3 vertically moves up and down relative to support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com