t-joint

A technology of rod handle and assembly, which is applied in the direction of wrench, wrench, screwdriver, etc., can solve the problems of being unable to bear on the pivot lug 112 to disperse stress, breakage, etc., to achieve enhanced safety and durability, ensure fastness, and avoid The effect of component slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

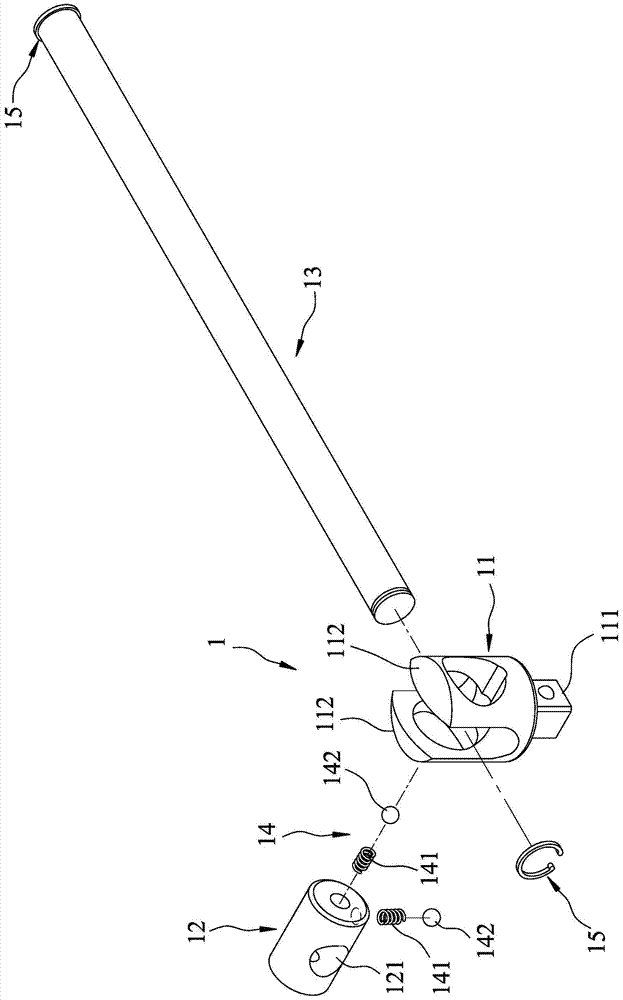

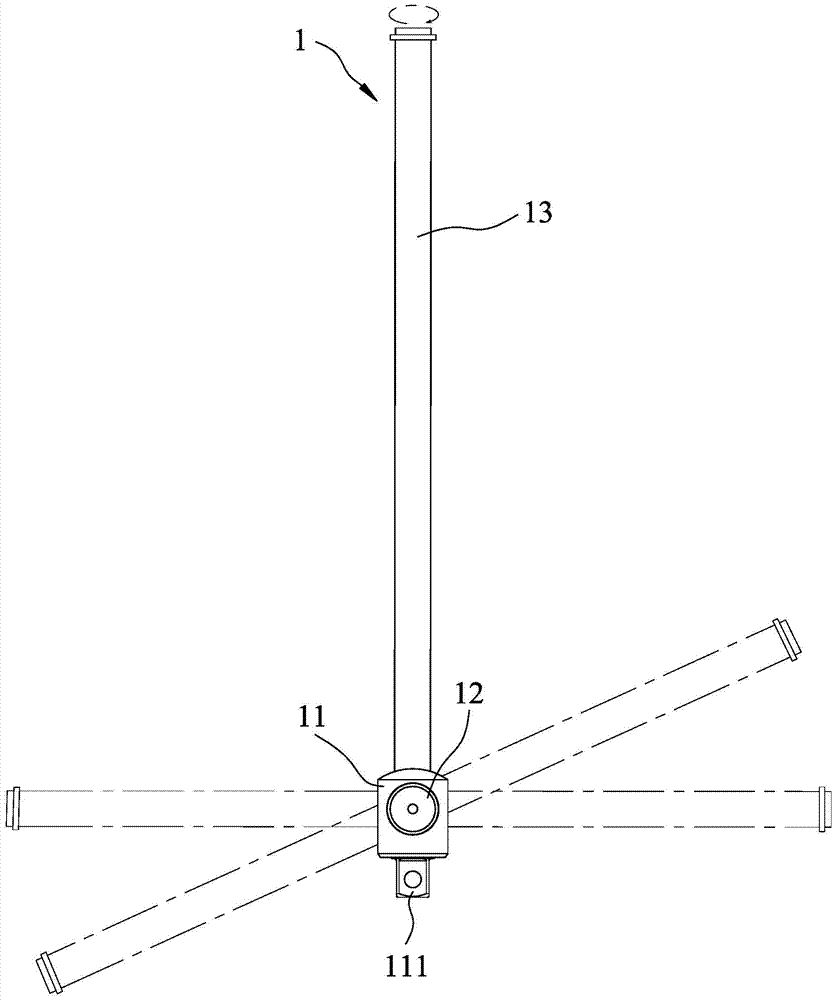

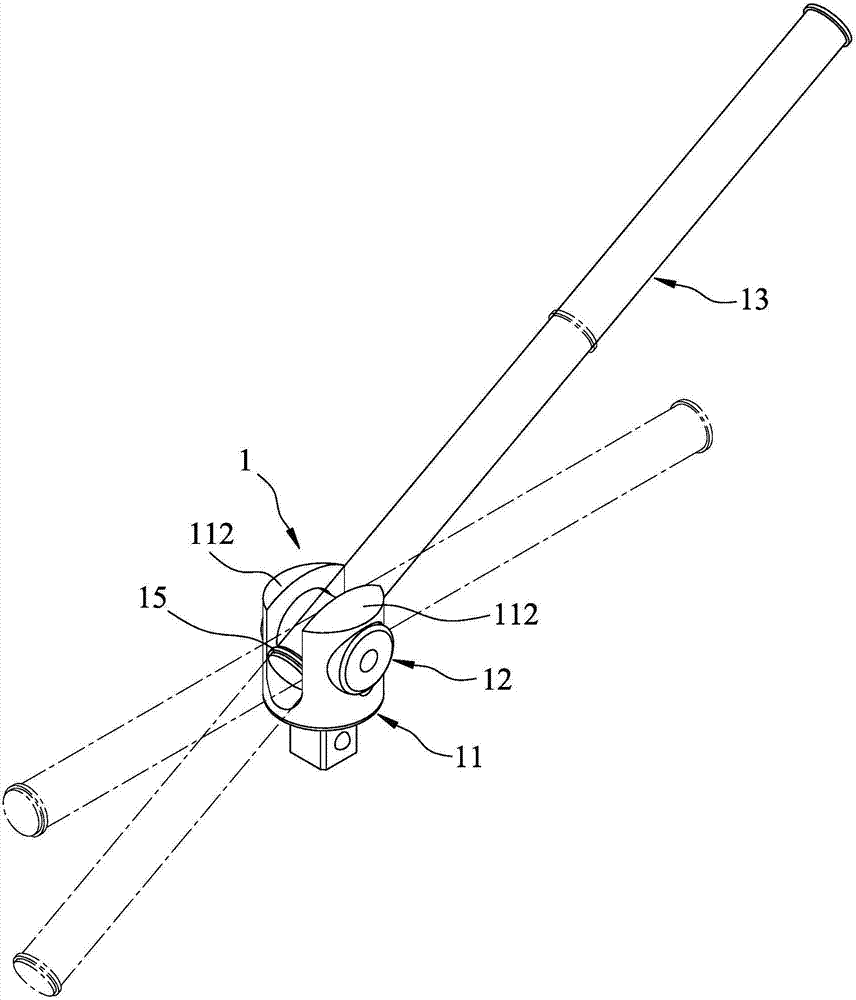

[0049] refer to Figure 5 and Figure 6 , The first embodiment of the T-shaped connecting rod of the present invention includes a shaft seat 2 , a connecting shaft 3 , a special-shaped handle 4 , and a clamping unit 5 .

[0050] The shaft seat 2 includes a body 21, two pivot lugs 22 extending outwardly from the body 21 at intervals from each other, and a pivot lug 22 extending outwardly from the body 21 opposite to the pivot lug 22 and capable of connecting with the pivot lug 22. The driving end 23 matched with different sleeves (not shown). The pivot ears 22 are respectively provided with a circular pivot hole 221 .

[0051] The assembly shaft 3 is generally cylindrical, can rotate around its own axis, pass through the pivot hole 221 and is positioned on the pivot ear 22, and includes an outer surface 31 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com