Method for forming cut line and device for forming cut line

A cutting line and circular technology, which is applied in the field of cutting line forming method and forming device, can solve problems such as difficulty in stably achieving high lamination accuracy, and achieve the effects of reducing lamination failure, improving lamination accuracy, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

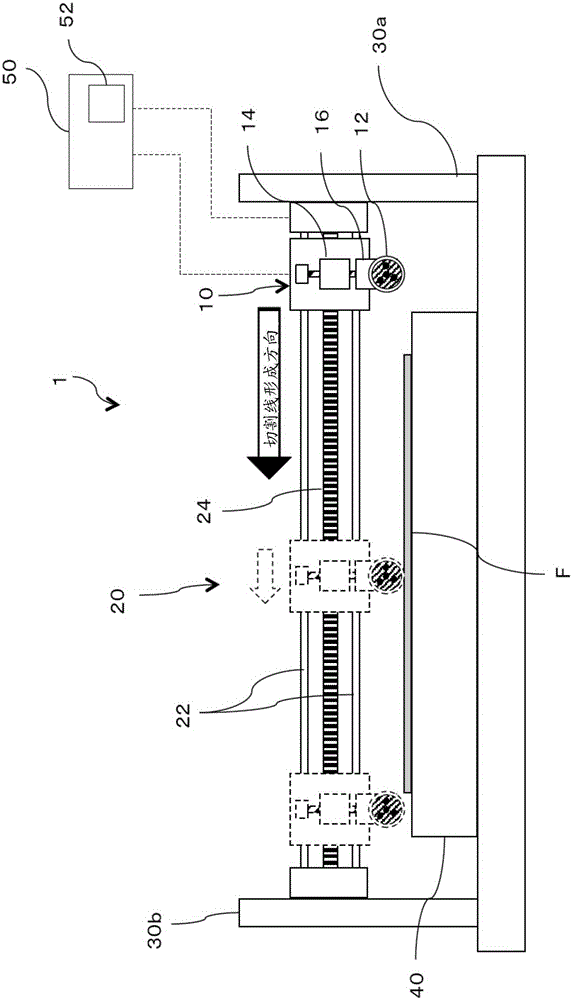

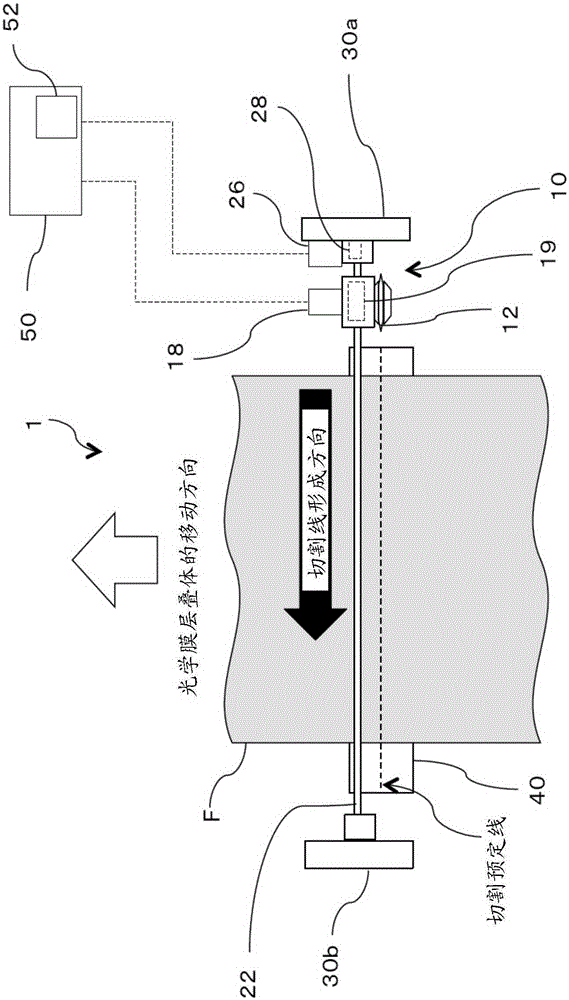

[0072] figure 2 It is a schematic side view showing the configuration of the dicing line forming apparatus 1 according to the first embodiment of the present invention, image 3 It is a schematic plan view showing the structure of the dicing line forming apparatus 1 . In this embodiment, the rotational speed of the circular cutter 12 is read by a detection unit such as an encoder, and the circular cutter 12 is set to a reference state based on the read result. The dicing line forming apparatus 1 includes the dicing unit 10 that cuts the optical film laminate F, and the dicing unit moving mechanism 20 that reciprocates the dicing unit 10 in the width direction of the optical film laminate F (cut line forming direction). The dicing line forming apparatus 1 further includes a dicing table 40 on which the optical film laminate F is placed.

[0073] The cutting unit 10 includes a circular blade 12 , a height adjustment unit 14 that adjusts the position of the circular blade 12 w...

no. 2 approach

[0096] Next, a dicing line forming apparatus 1' according to a second embodiment of the present invention will be described. Figure 7 It is a schematic plan view showing the configuration of the dicing line forming apparatus 1' according to the second embodiment of the present invention, Figure 8 A dicing line forming method 300 according to the second embodiment is shown. In this embodiment, for example, a reading unit using a camera or the like can read a mark or the like on the side surface of the circular cutter 12, and based on the read result, the circular cutter 12 can be set as Baseline status.

[0097] The basic structure of the cutting line forming apparatus 1' is the same as that of the cutting line forming apparatus 1 of the first embodiment, except that the cutting line forming apparatus 1' is provided with a reading part 32 and an illumination 34, and the reading part 32 and the illumination 34 can read the mark M marked on the side surface of the circular cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com