Slitting mechanism for bamboo split roll

A technology of bamboo strip roll and transmission mechanism, which is applied in metal processing and other directions, to achieve the effect of avoiding the phenomenon of threading, reasonable structure and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

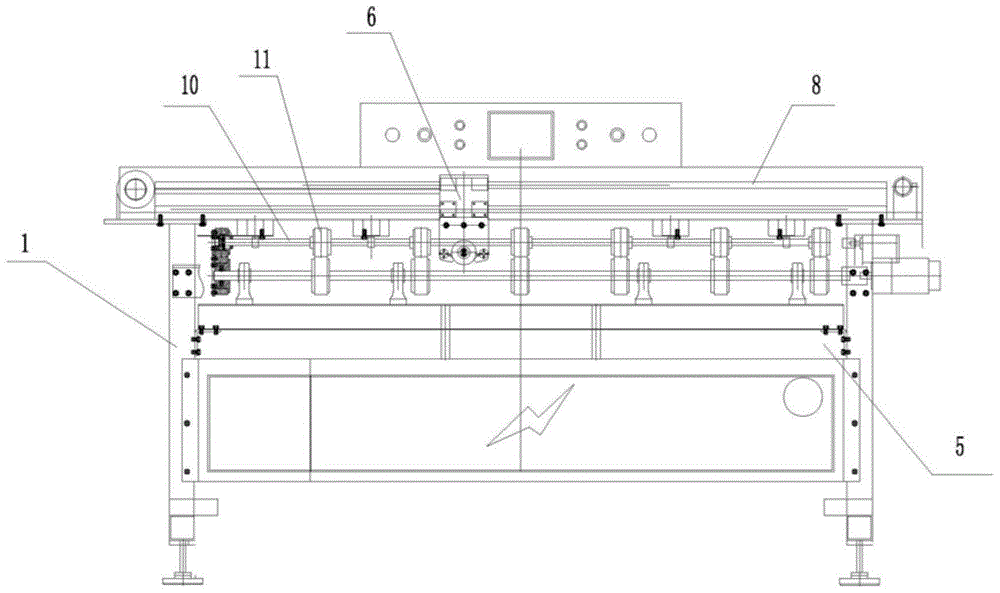

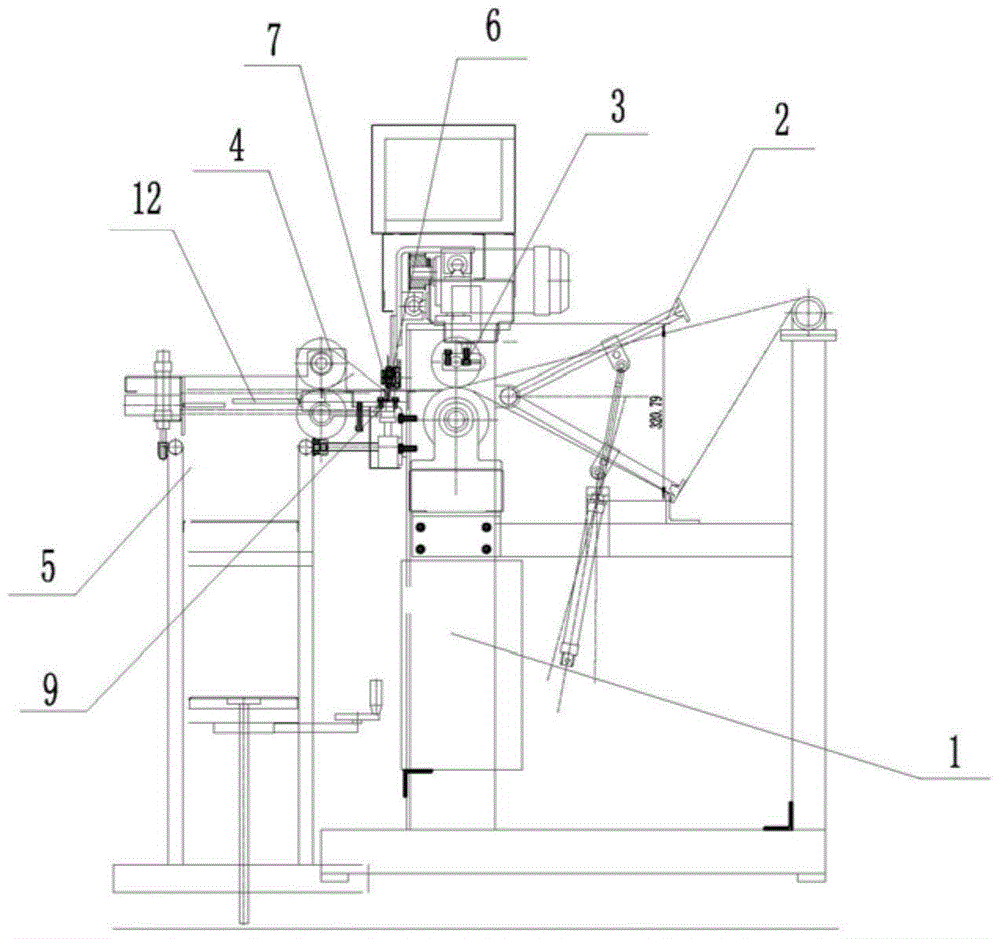

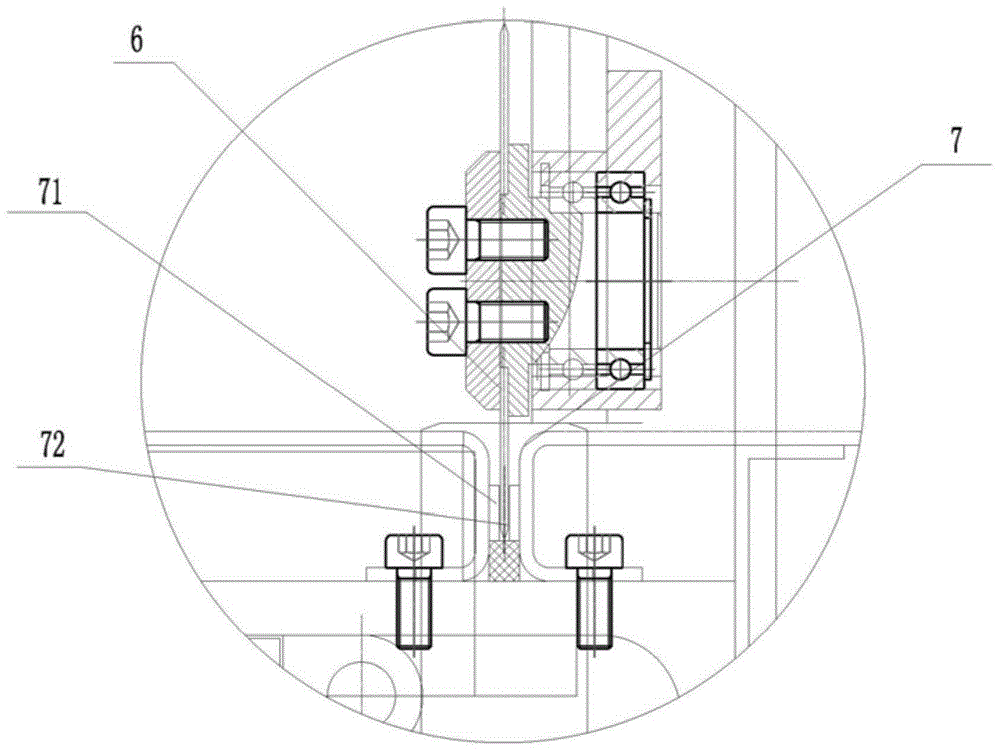

[0021] Example: such as Figure 1-2 , a cutting mechanism for bamboo strips rolls, comprising a frame 1, a cutting device 6 is provided on the frame 1, a rear transmission mechanism 3 for feeding is provided at the rear of the cutting device 6, and a rear transmission mechanism 3 is provided at the front of the cutting device 6. The front conveying mechanism 4 that plays a role in unloading is provided with a discharge port 5 in front of the forward conveying mechanism 4 . Among them, the front transmission mechanism 4 and the rear transmission mechanism 3 both include two rotatable shafts 10, and two opposite rollers 11 are distributed on the two shafts at intervals. transmission.

[0022] In use, the bamboo strip roll is conveyed and fed by the rear transmission mechanism 3, and the transmission is stopped after the bamboo strip roll is controlled to travel a certain distance. The cutting device 6 cuts it, and the front transmission mechanism 4 unloads the cut bamboo strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com