Method for manufacturing stone panel model mold

A production method and technology of stone slabs, applied in the field of construction, can solve problems such as insufficient mold lines, waste of company resources and manpower, material resources, and insufficient designs and colors, and achieve the effect of clear mold lines and increased types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

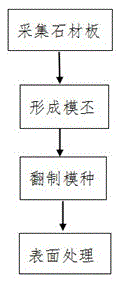

[0017] According to one aspect of the present invention, the manufacturing method of described stone plate mold kind comprises the steps:

[0018] A) collecting stone boards;

[0019] B) utilizing silica gel to turn over the texture of the stone plate to form a mold;

[0020] C) utilize described mold to turn over the model type;

[0021] D) Surface treatment of the model.

[0022] Preferably, the surface treatment method of the model in the step D) is polishing and / or grinding.

Embodiment 2

[0024] According to one aspect of the present invention, the manufacturing method of described stone plate mold kind comprises the steps:

[0025] A) collecting stone boards;

[0026] B) utilizing silica gel to turn over the texture of the stone plate to form a mold;

[0027] C) utilize described mold to turn over the model type;

[0028] D) Surface treatment of the model.

[0029] Preferably, the step C) is to use epoxy resin to make the stone plate mold.

[0030] The invention provides a method for making a stone slab mold, comprising the following steps: A) collecting the stone slab; B) using silica gel to remake the texture of the stone slab to form a mold; C) using the mold to turn the mold ; D) Surface treatment of the model. Due to the adoption of novel mold patterns and special materials, the mold patterns produced by the method for making the stone plate molds are clear, and the types of decorative plates in the market are increased, allowing consumers to have mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com