Miniature garbage treatment equipment

A kind of garbage disposal equipment and miniature technology, which is applied in the direction of garbage cans, garbage collection, garbage cleaning, etc., and can solve the problems of long processing cycle, high cost, and large garbage volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

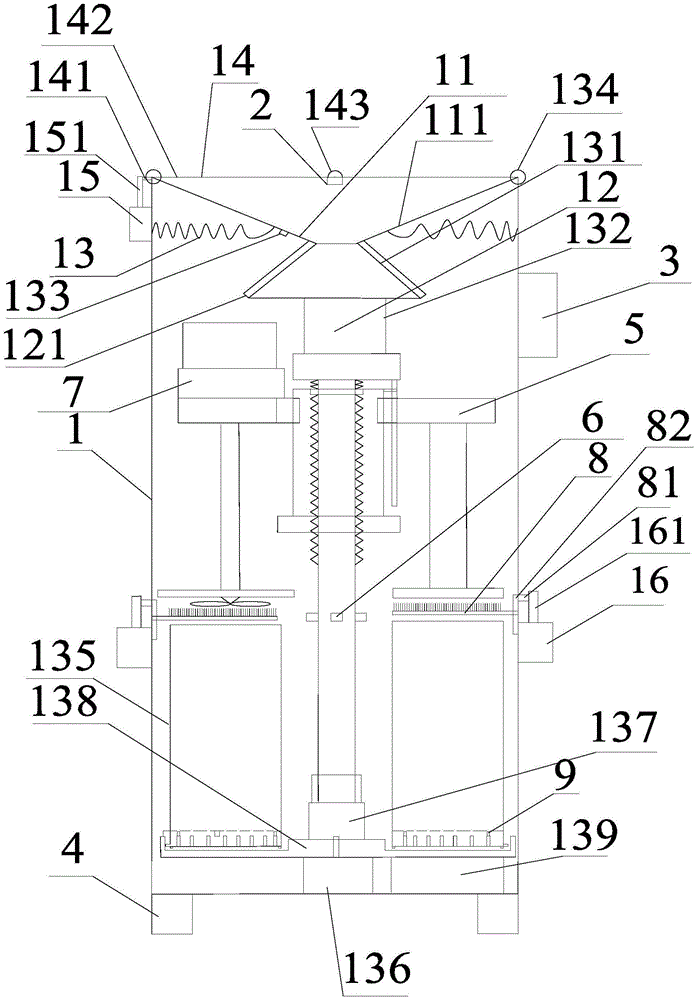

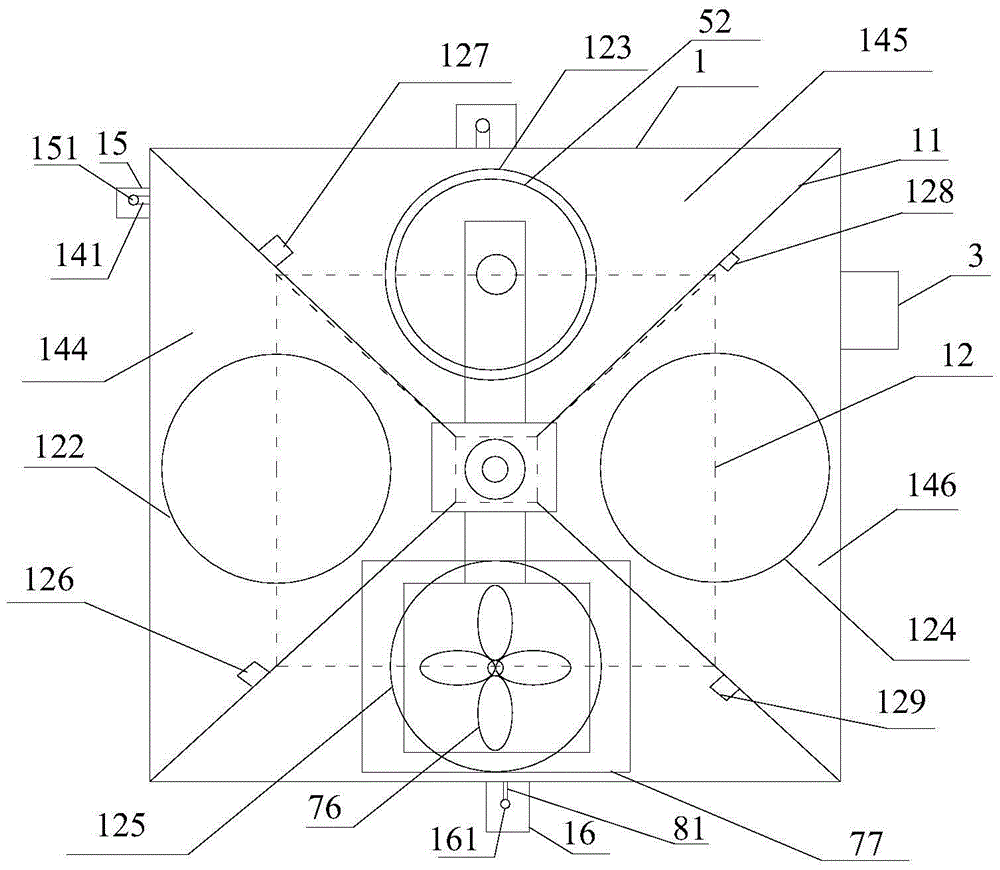

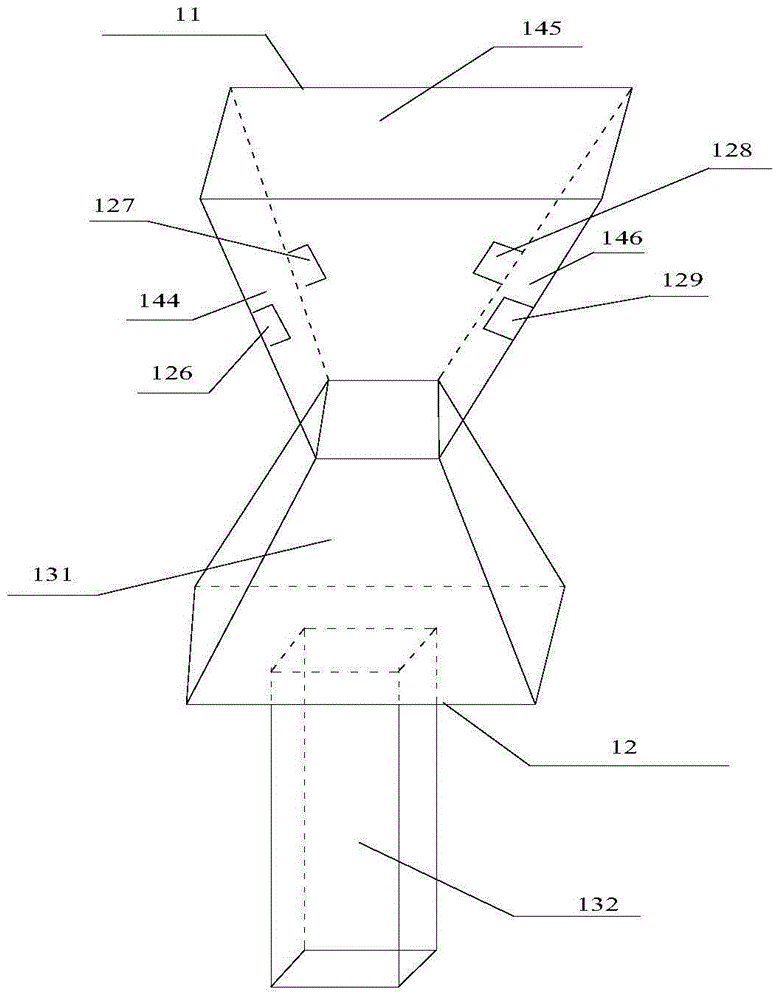

[0075] Embodiments of the present invention are as follows, as figure 1 , a kind of micro-waste processing equipment, including a box body 1, a cutting device 7 and / or a compression device 5, and a controller 3, an inner barrel 135 is arranged in the box body 1, and the inner barrel 135 includes a bottom plate 1358 and a side wall, and the The inner barrel 135 is divided into two layers by the partition plate 1353, the bottom plate 1358 is provided with a plurality of protrusions 1359, and the upper part of the at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com