Automatic sorting equipment

An automatic sorting and equipment technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as poor posture, damaged goods, and uneven processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

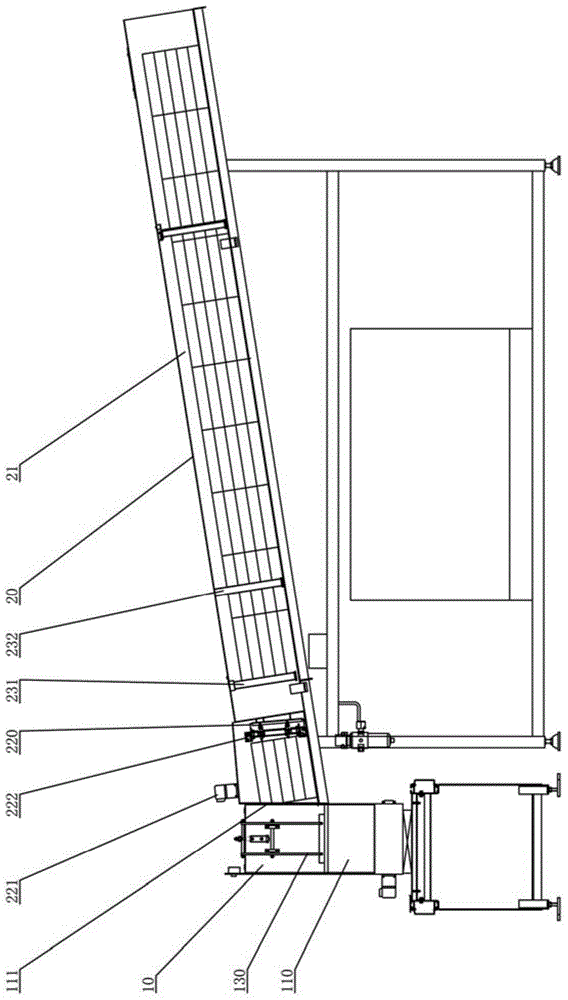

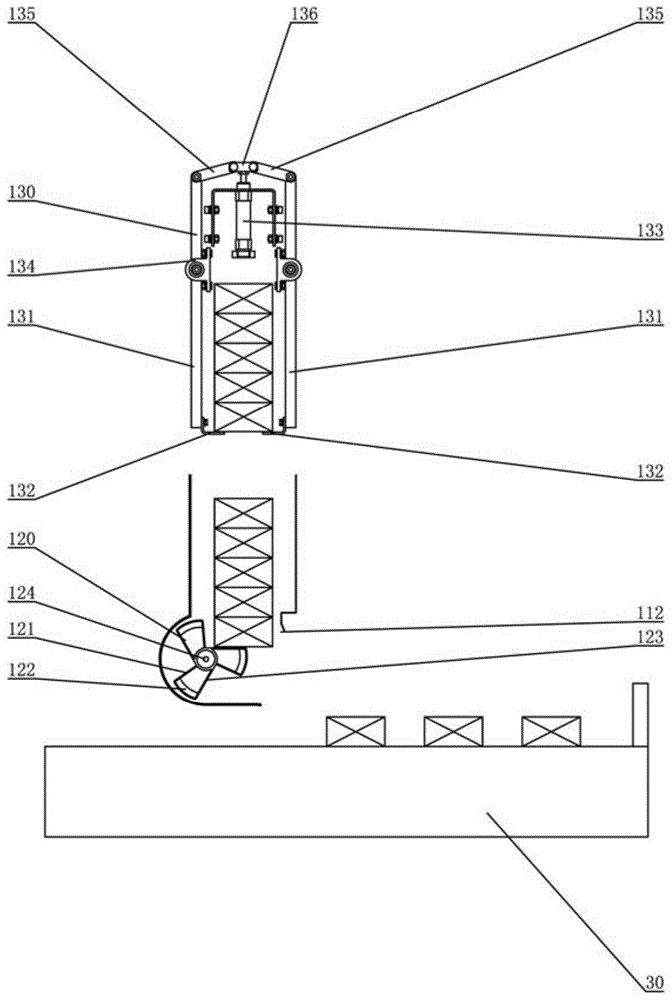

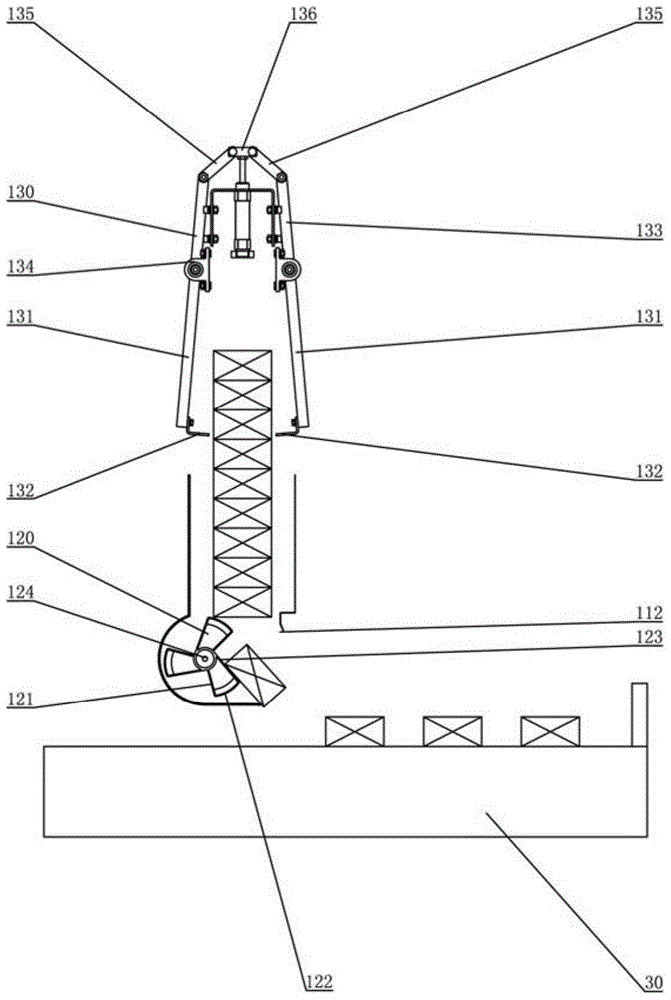

[0016] Such as figure 1 , 2As shown, an automatic sorting device includes a dial-type sorting device 10 and a cargo buffer device 20. The dial-type sorting device 10 includes a vertical channel 110 and a drawer arranged in the vertical channel 110. The plate type unloading mechanism 130 is provided with an inlet 111 on the upper part of the vertical passage 110, an outlet 112 on the lower part, a dial 120 is arranged near the outlet 112, and a conveying device 30 is arranged below the outlet 112. , the cargo storage device 20 is disposed on the side of the entrance 111 . The cargo buffer device 20 includes a cargo passage 21 and a replenishment mechanism 220 disposed on the cargo passage 21 near the vertical passage 110 . The height from the ground of the side of the cargo channel 21 away from the vertical channel 110 is greater than that of the side of the cargo channel 21 close to the vertical channel 110 , and the bottom of the cargo channel 21 is provided with sliding wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com