Wheel type movable bearing crowbar

A wheel type and load-bearing wheel technology, which is applied in the direction of crowbars and lifting devices, can solve the problems of inability to use cranes, heavy transformers, and moving obstacles, and achieve the effects of saving manpower and material resources, saving costs, and being easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

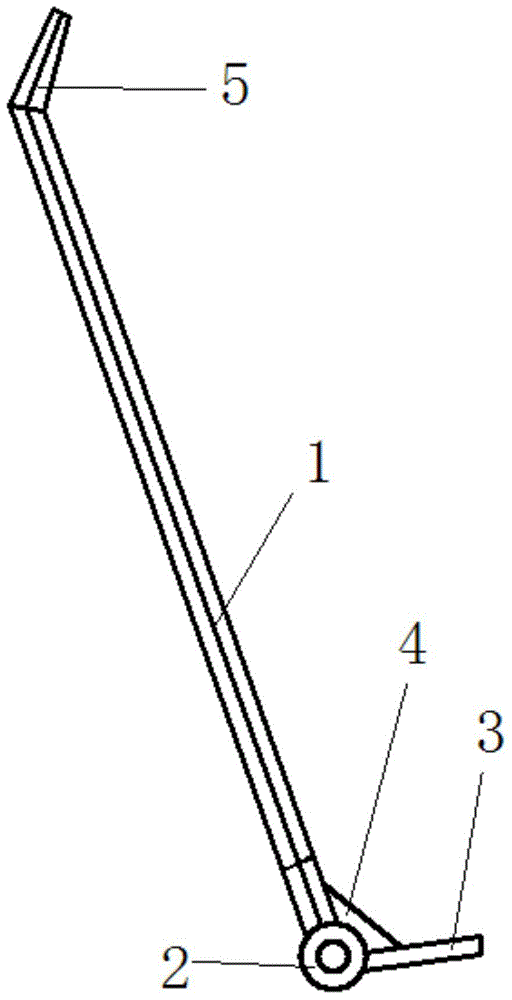

[0015] This embodiment provides a wheel-type load-bearing movable crowbar, which is characterized in that: the wheel-type load-bearing movable crowbar includes a crowbar 1, a load-bearing wheel 2, a crowbar 3, a triangular reinforcing rib 4, a small crowbar plate 5;

[0016] Among them: the bottom of the crowbar 1 is welded to the crowbar 3, and the obtuse angle between them is 100°; two load-bearing wheels 2 are installed at the joint between the crowbar 1 and the crowbar 3; the upper part of the welding part between the bottom of the crowbar 1 and the crowbar 3 is welded There is a triangular reinforcing rib 4; a small crowbar 5 is welded on the top of the crowbar 1, and the obtuse angle between the crowbar 1 and the small crowbar 5 is 100°.

[0017] The load-carrying wheel 2 is a rolling bearing.

[0018] Described skid plate 3 structure is the steel plate of long 150 millimeters, wide 60 millimeters, thick 5 millimeters.

[0019] Described small skid plate 5 structures a...

Embodiment 2

[0022] This embodiment provides a wheel-type load-bearing movable crowbar, which is characterized in that: the wheel-type load-bearing movable crowbar includes a crowbar 1, a load-bearing wheel 2, a crowbar 3, a triangular reinforcing rib 4, a small crowbar plate 5;

[0023] Among them: the bottom of the crowbar 1 is welded to the crowbar 3, and the obtuse angle between them is 100°; two load-bearing wheels 2 are installed at the joint between the crowbar 1 and the crowbar 3; the upper part of the welding part between the bottom of the crowbar 1 and the crowbar 3 is welded There is a triangular reinforcing rib 4; a small crowbar 5 is welded on the top of the crowbar 1, and the obtuse angle between the crowbar 1 and the small crowbar 5 is 100°.

[0024] The load-carrying wheel 2 is a rolling bearing.

[0025] Described skid plate 3 structure is the steel plate of long 150 millimeters, wide 60 millimeters, thick 5 millimeters.

[0026] Described small skid plate 5 structures a...

Embodiment 3

[0029] This embodiment provides a wheel-type load-bearing movable crowbar, which is characterized in that: the wheel-type load-bearing movable crowbar includes a crowbar 1, a load-bearing wheel 2, a crowbar 3, a triangular reinforcing rib 4, a small crowbar plate 5;

[0030] Among them: the bottom of the crowbar 1 is welded to the crowbar 3, and the obtuse angle is 115°; two load-bearing wheels 2 are installed at the connection between the crowbar 1 and the crowbar 3; the upper part of the welding part of the bottom of the crowbar 1 and the crowbar 3 is welded There is a triangular reinforcing rib 4; the top of the crowbar 1 is welded with a small crowbar 5, and the obtuse angle between the crowbar 1 and the small crowbar 5 is 115°.

[0031] The load-carrying wheel 2 is a rolling bearing.

[0032] Described skid plate 3 structure is the steel plate of long 150 millimeters, wide 60 millimeters, thick 5 millimeters.

[0033] Described small skid plate 5 structures are long 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com