Dry double-sided knitted fabric of polyester filament and preparation method thereof

A technology of knitted fabrics and polyester filaments, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of unsuitable industrial production, complicated production process, and affecting the performance of fabrics, and achieve the unidirectional moisture-wicking function lasting and increasing The contact area and the effect of increasing the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

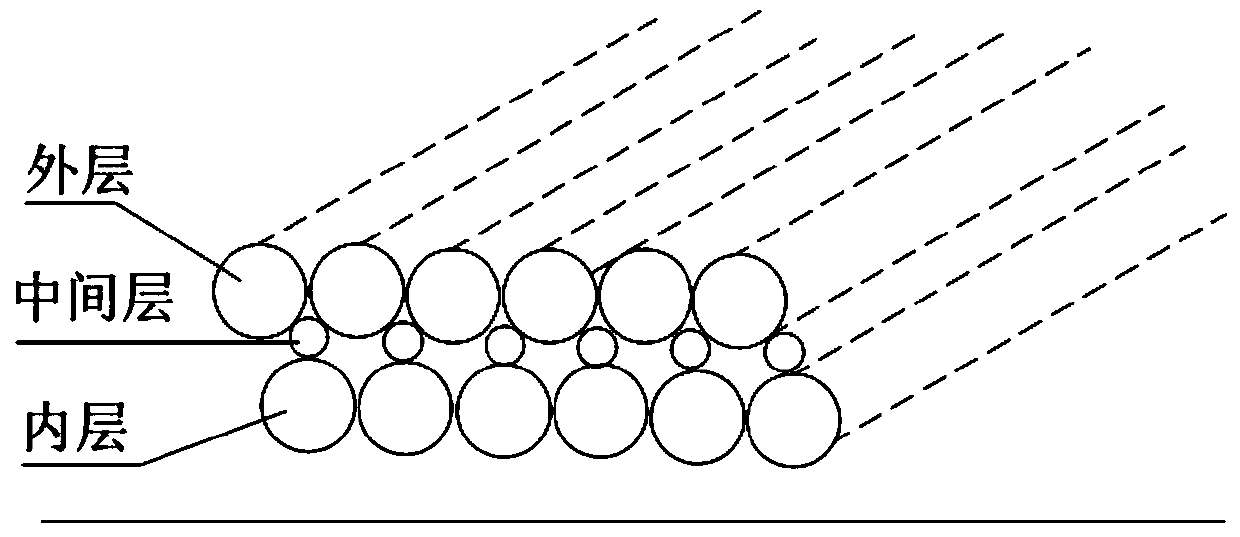

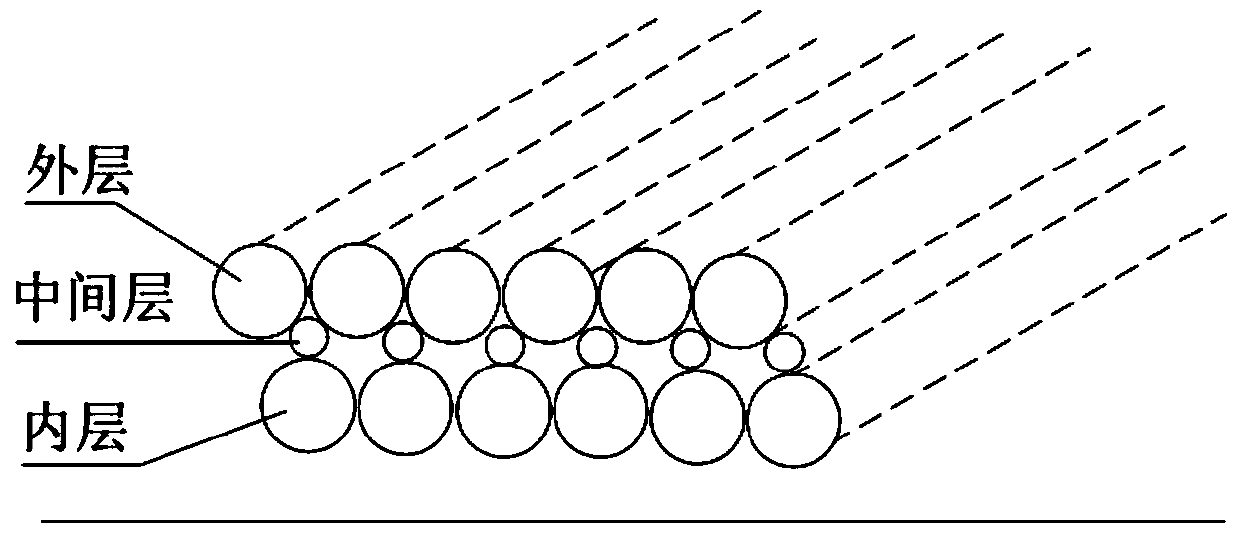

[0025] Such as figure 1 As shown, the present embodiment provides a dry double-sided knitted fabric of polyester filament, the fabric is a double-sided knitted structure, the outer layer is full-dull superfine denier fiber or microporous fiber, and the middle layer is a water-conducting fabric. Fiber, the inner layer is cool feeling fiber with special-shaped cross-section; the monofilament fineness of the cool-feeling fiber with special-shaped cross-section is 3 times that of the outer layer fiber. Among them, the yarn count of the outer layer fabric is 75D / 144F; further, the yarn count of the middle layer fabric is 75D / 36F; further, the yarn count of the inner layer fabric is: 75D / 48F polyester DTY+84T / 45F cupro.

[0026] Specifically adopt the following method to prepare:

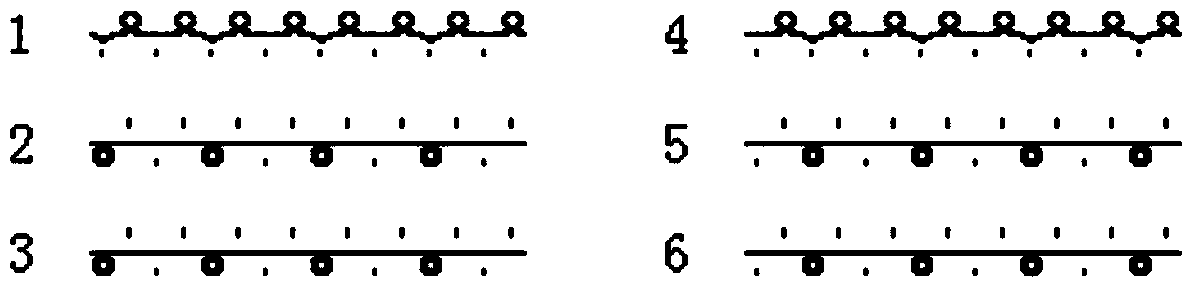

[0027] Step 1: Weave cool-feeling fibers with special-shaped cross-sections, water-conducting fibers, full-dull ultra-fine denier fibers or microporous fibers on a double-sided large circular machine, st...

Embodiment 2

[0035] Such as figure 1 As shown, the present embodiment provides a dry double-sided knitted fabric of polyester filament, the fabric is a double-sided knitted structure, the outer layer is full-dull superfine denier fiber or microporous fiber, and the middle layer is a water-conducting fabric. Fiber, the inner layer is cool feeling fiber with special-shaped cross-section; the monofilament fineness of the cool-feeling fiber with special-shaped cross-section is 4 times that of the outer layer fiber. Among them, the yarn count of the outer layer fabric is 75D / 72F; further, the yarn count of the middle layer fabric is 75D / 72F; further, the yarn count of the inner layer fabric is: 75D / 48F polyester DTY+84T / 45F cupro.

[0036] Specifically adopt the following method to prepare:

[0037] Step 1: Weave cool-feeling fibers with special-shaped cross-sections, water-conducting fibers, full-dull ultra-fine denier fibers or microporous fibers on a double-sided large circular machine, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com