Textile humidification device

A humidification device, textile technology, applied in the direction of processing textile material equipment configuration, spray/jet textile material processing, etc., can solve the problems of increasing production cost, investment and operation cost, achieve reasonable structure, reduce investment and operation cost, and improve The effect of promoting utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

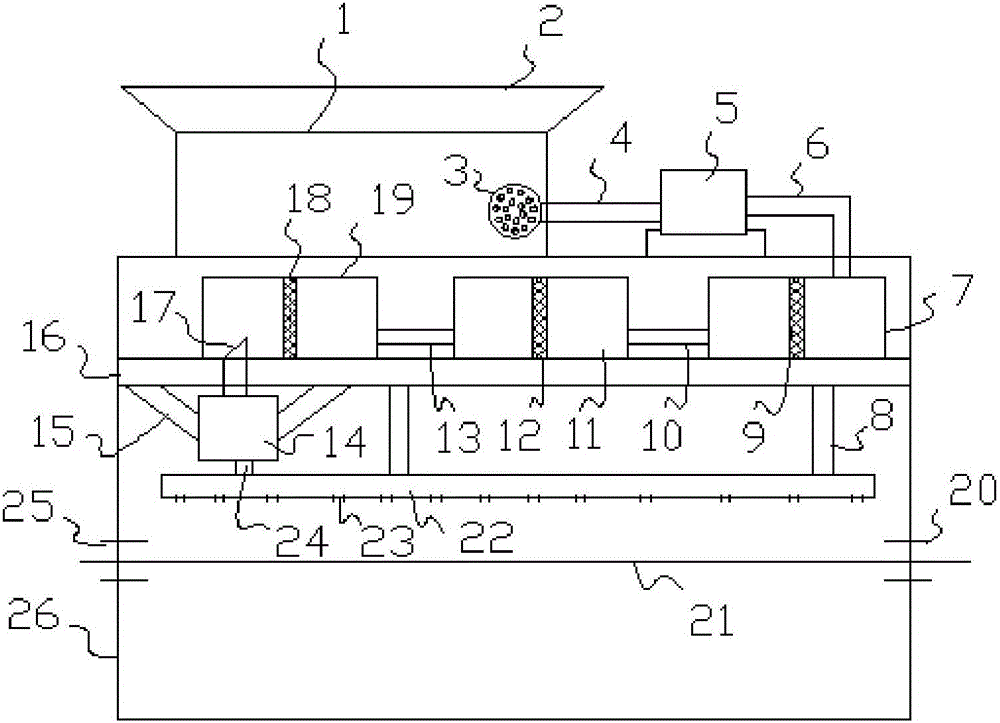

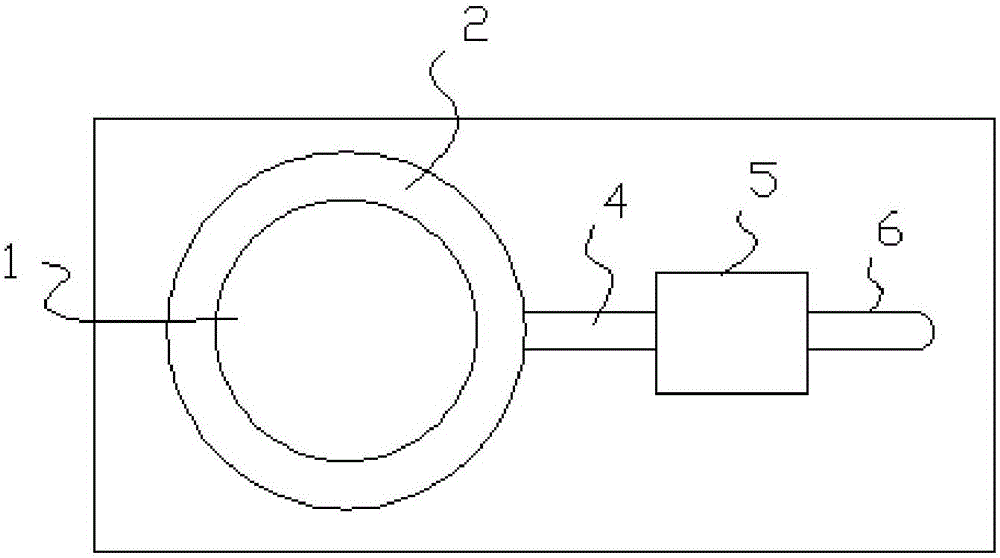

[0020] Such as figure 1 , figure 2 As shown, the humidifying device for this kind of textiles has a structure including a working chamber 26, and a sump 1 is arranged above the working chamber 26, and the sump 1 is connected with the suction pump 5 through the absorption pipe 4, and the absorption pipe 4 The left end of the pump is provided with a spherical filter 3; the right side of the suction pump 5 is connected to the water inlet pipe 6, and the other end of the water inlet pipe 6 is bent downwards and enters the working chamber 26, and is connected with the first box body 7. When in use, the sump can collect rainwater, and the spherical filter can initially intercept the sundries in the rainwater to prepare for the humidification of the textiles behind.

[0021] In the above-mentioned embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com