Novel paper pulp molded product hot pressing machine

A technology of pulp molding and hot press, which is applied to conveyors, conveyor objects, textiles and papermaking, etc. It can solve the problems of wasting plant space, increasing labor costs, and affecting productivity, so as to improve production efficiency and save labor costs. , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

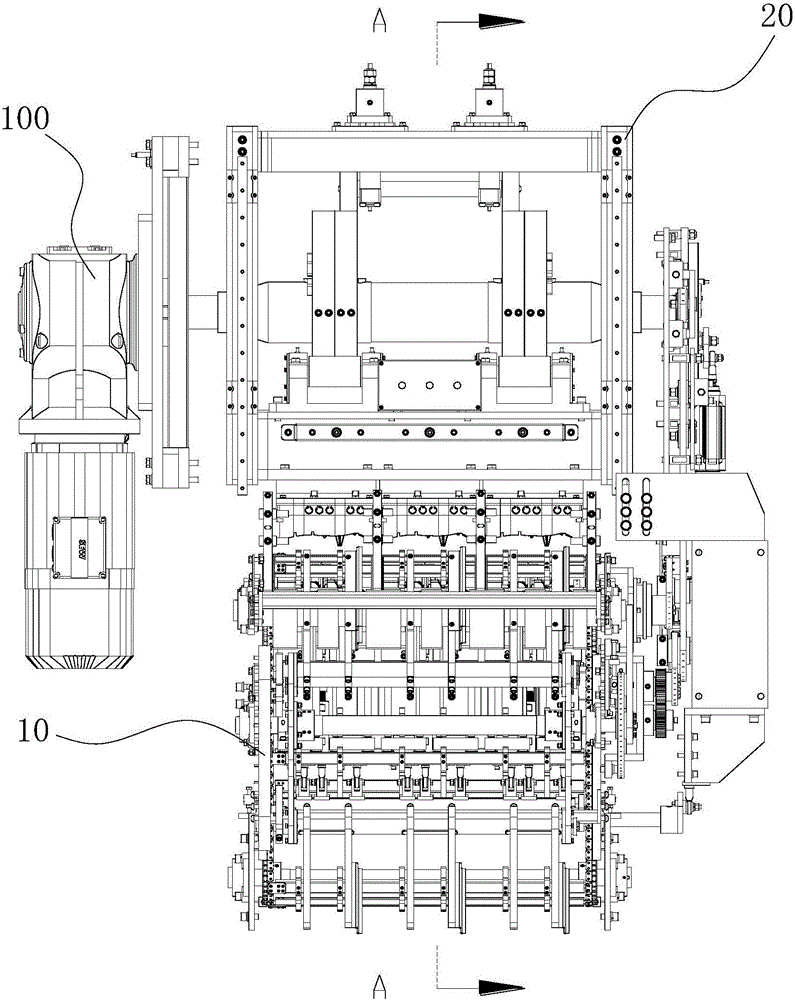

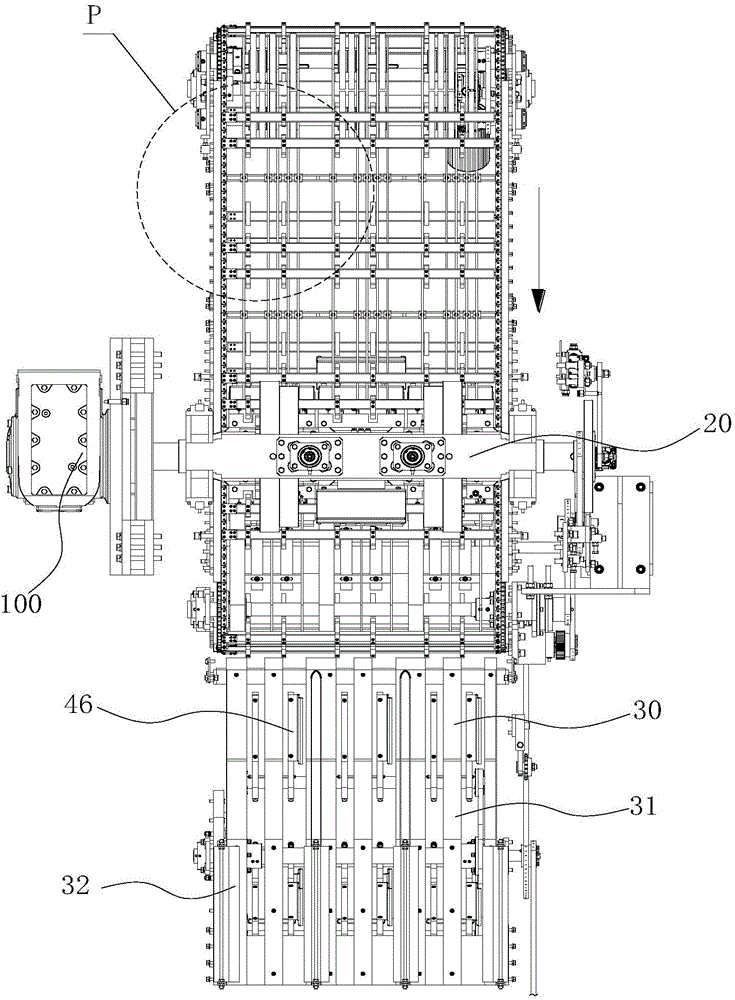

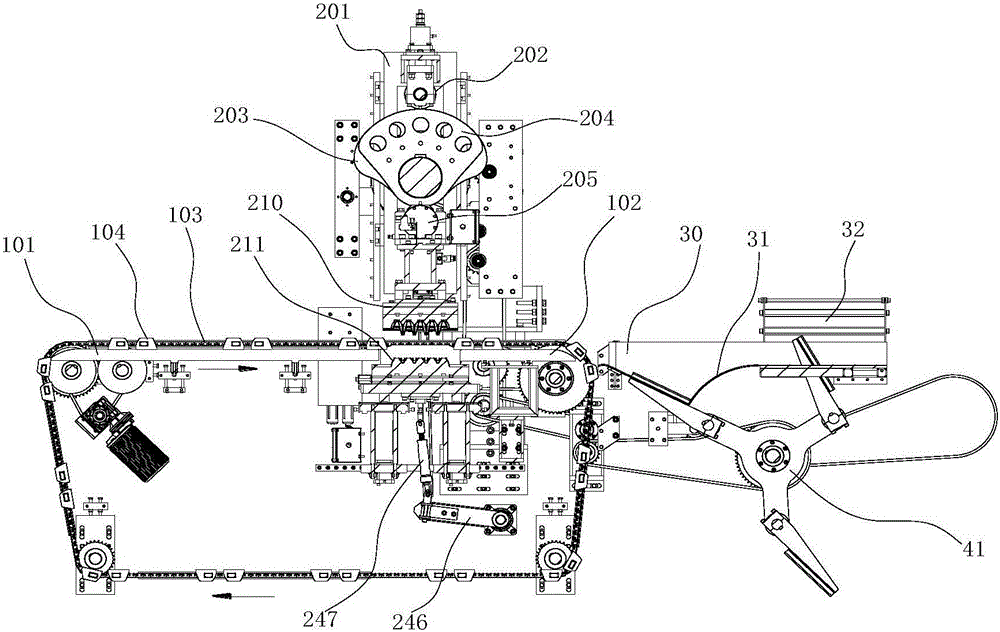

[0036] like Figure 1-11 As shown, the new heat press machine for pulp molding products includes: a frame 10, a gantry frame 20, a movable frame body 201, a heat press device, a stepping conveying device, and a stacking device.

[0037] according to Figure 1-3 As shown, the frame 10 provides a mounting and supporting base for each component.

[0038] The gantry 20 is installed in the middle of the frame 10, and a movable frame body 201 is arranged in the gantry frame 20, and a driving movable frame body 201 is arranged between the gantry frame 20 and the movable frame body 201 to move along the height direction of the gantry frame 20. Reciprocating drive mechanism.

[0039] The hot-pressing device is used for hot-pressing the paper blank 50, and includes a movable upper mold 210 and a lower mold 211 located below the upper mold 210, the upper mold 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com