Processing method for reduction in formation pressure of carbonatite single well

A technology to reduce formation pressure and formation pressure, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc. It can solve the problems of reduced production, difficult to accurately determine the amount of water injection, and prone to water flooding, etc., to achieve low cost, The effect of increasing single well production and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

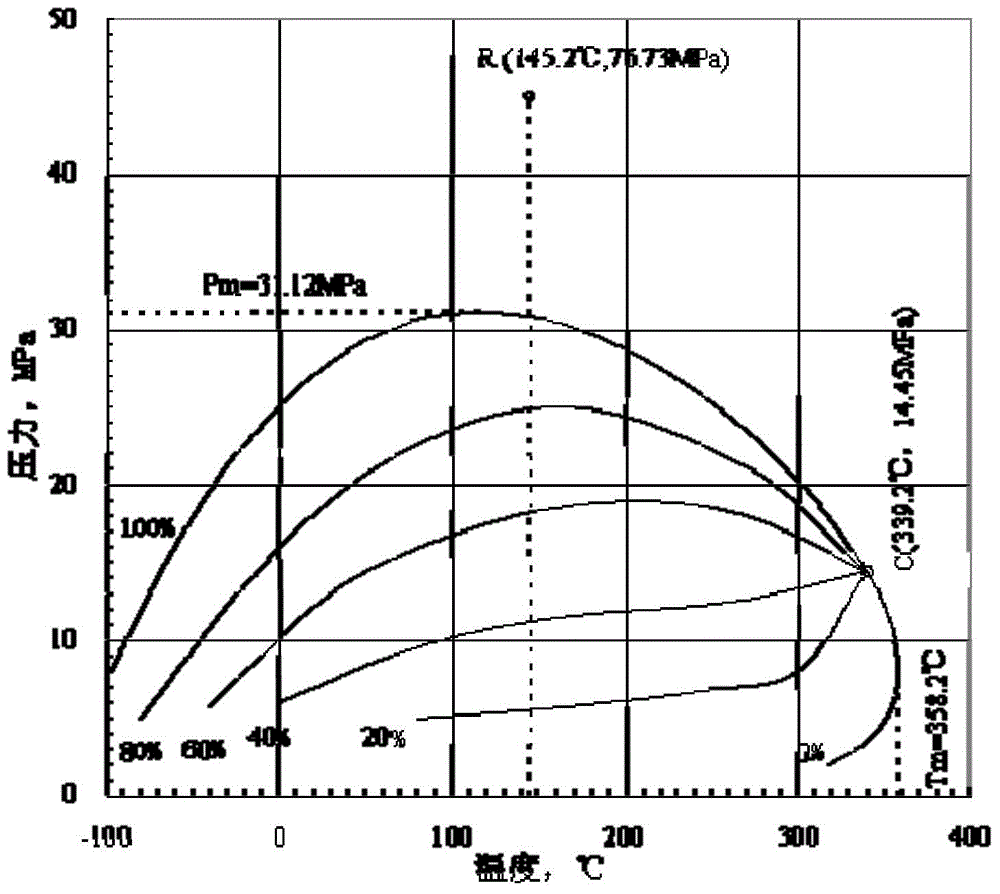

[0039] Embodiment 1 The method of the present invention is used to process when the formation pressure of a single carbonate well is lower than its reservoir saturation pressure.

[0040] A single carbonate well with a depth of 6994.61m belongs to a volatile light oil reservoir. The original formation pressure of the single well is 76.88MPa. Since the well belongs to a cave-type reservoir with weak water energy, the formation pressure drops rapidly after being put into production After 10 months of production, the formation pressure of the well dropped below the saturation pressure, formation degassing occurred, the gasoline ratio rose rapidly from less than 600 to 3500, the daily oil production dropped from 30 tons to 3 tons, and the density of crude oil dropped sharply.

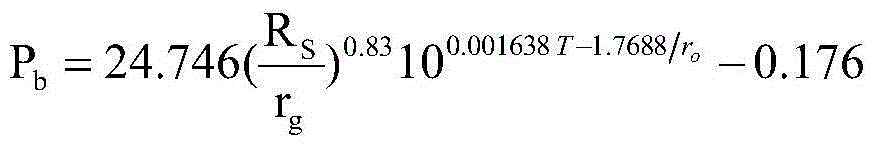

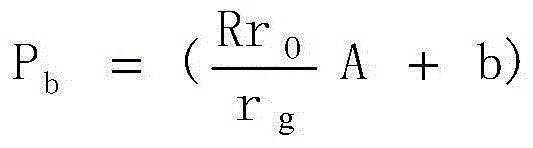

[0041] When adopting the method of the present invention, the formation pressure of this carbonate single well is processed as follows when it is lower than its reservoir saturation pressure:

[0042] 1) me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com