Stainless steel faucet

A stainless steel, faucet technology, applied in valve details, threaded connections, valve shell structure, etc., can solve problems such as shortening product service life, environmental pollution, rough inner and outer surfaces, etc., to prolong service life, reduce environmental pollution, and material structure. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

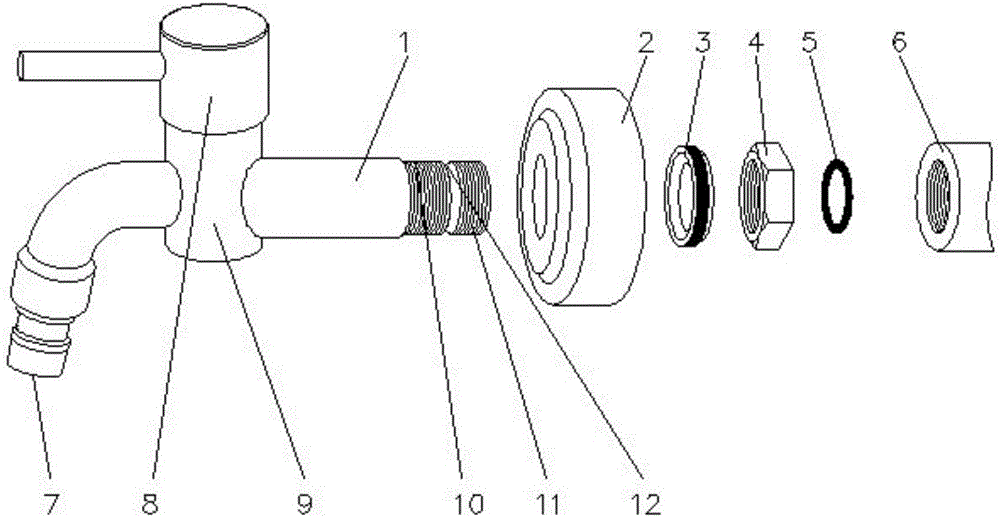

[0013] See figure 1 , The present invention provides a technical solution: a stainless steel faucet, including a water inlet nozzle 1, a decorative cup 2, a non-slip rubber ring 3, a nut 4, an "O" seal ring 5, a nozzle 6, a water outlet 7, and a handle 8. , Spool 9, positioning thread 10, interface thread 11 and "O"-shaped sealing slot 12, the water inlet pipe 1 is connected with the valve core 9, the handle 8 is installed at the upper p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap