Heat dissipation module of LED tunnel lamp

A technology for LED tunnel lights and heat dissipation modules, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, outdoor lighting, etc. It can solve problems such as inconvenient assembly and poor heat dissipation effect, and achieve weight reduction and high product concentration. , Easy to deform and bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

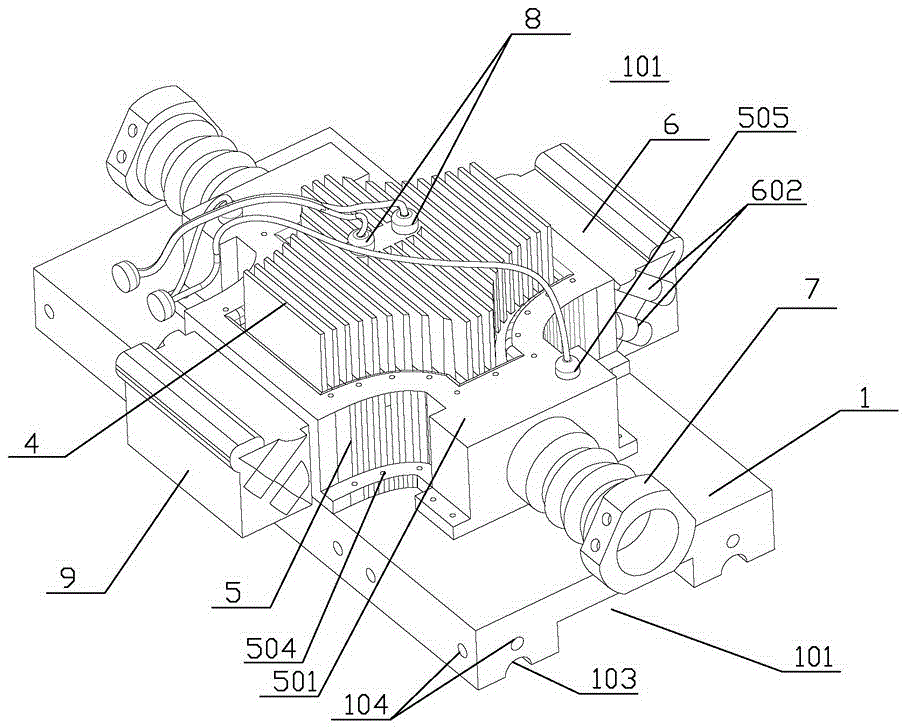

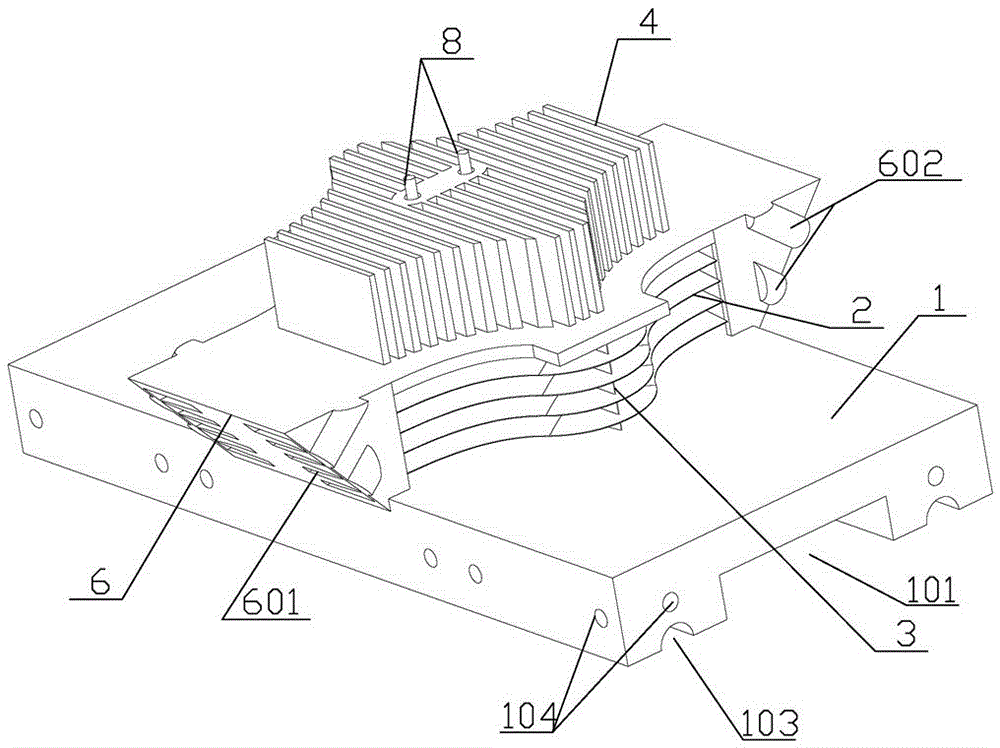

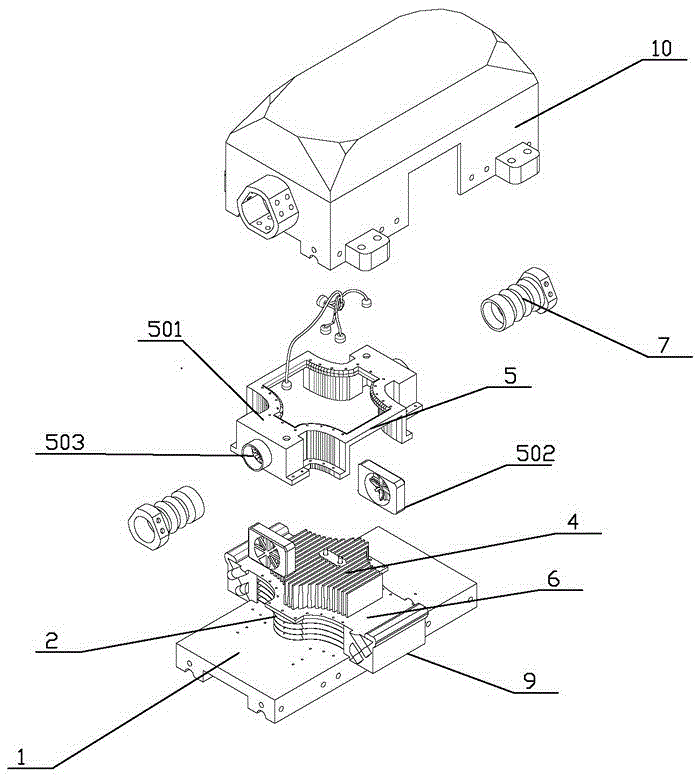

[0028] A heat dissipation module for an LED tunnel lamp, comprising a rectangular base plate 1, a heat sink horizontal fin assembly is provided on the middle upper surface of the long side of the base plate 1, the heat sink horizontal fin assembly includes a set of heat sink horizontal fins 2, the heat sink horizontal The cooling fins 2 are stacked vertically, and there is a gap between every two adjacent heat sink horizontal cooling fins 2, and at the gap between every two adjacent heat sink horizontal cooling fins 2 Both are provided with vertical air-dividing blades 3, the vertical air-dividing blades 3 and the vertical line of the short side of the base plate 1 are on a straight line, and the length of the vertical air-dividing blades 3 is less than the length of the base plate 1, and the heat sink horizontal fins 2 is a rectangular plate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com