Method for detecting light source calibration of standard light source coloring observation box

A calibration detection method and standard light source technology are applied in the field of light source calibration and detection of standard light source color observation box, which can solve the problems of high price, unrealistic, fluorescent lamp measurement error of spectrum analyzer, etc., to achieve accurate measurement accuracy and improve accuracy. performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

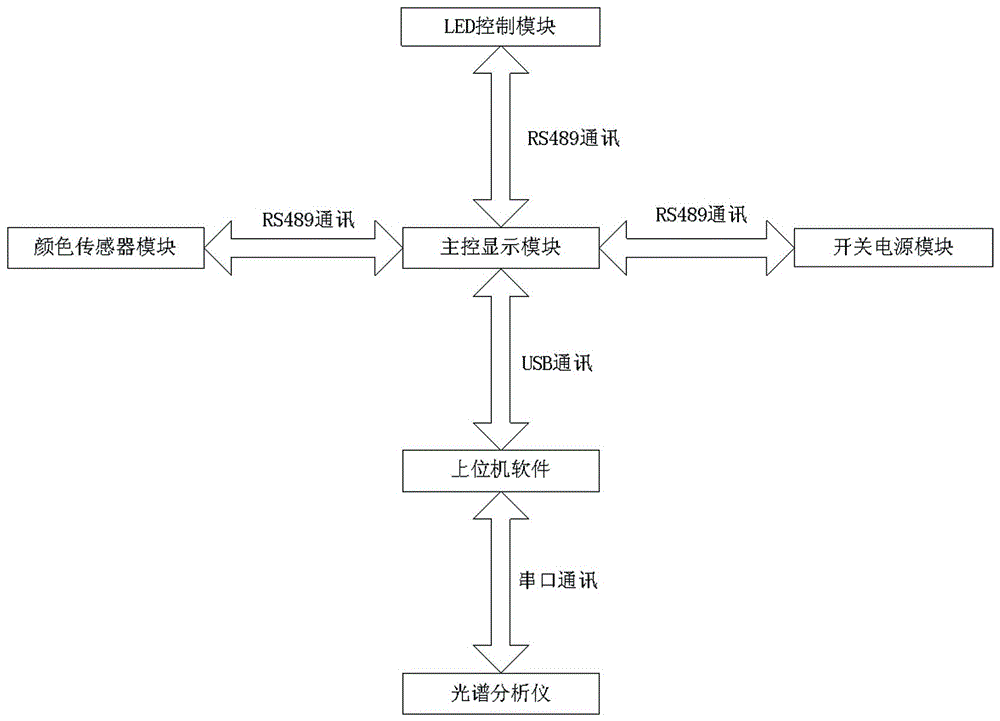

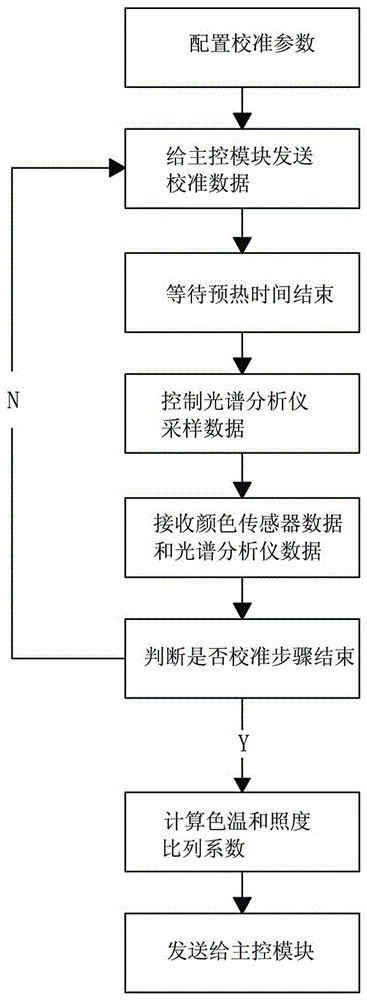

[0033] like figure 1 , 2 As shown, it is a specific embodiment of the light source calibration detection method of the standard light source color observation box of the present invention. In this embodiment, the color observation box samples the XYZ data of the light source through an external spectrum analyzer before leaving the factory, and the RGB data of the light source is sampled by the color sensor set in the color observation box, and the matrix coefficient between the RGB data and the XYZ data is calculated. , and send the matrix coefficients to the main control module of the color matching observation box for storage; after the observation box leaves the factory, the RGB data sampled by the color sensor and the matrix coefficients are calculated to obtain the XYZ data, and the XYZ data is calculated to obtain the color temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com