Multiple magnetic head constant-temperature conductivity cell

A technology of conductivity cell and magnetic head, applied in the direction of fluid resistance measurement, etc., can solve the problems of time-consuming and complicated operation, and achieve the effects of preventing uneven mixing, adding temperature sensors, and clear functional division.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

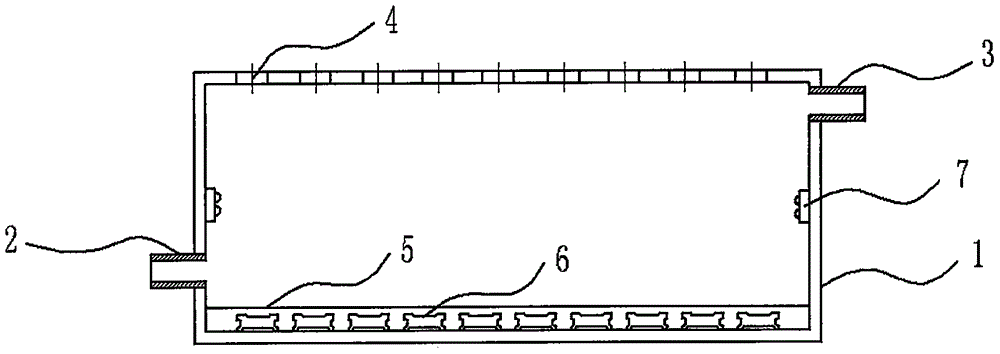

[0015] Such as figure 1 As shown, the present invention discloses a multi-head constant temperature conductivity cell, which includes a conductivity cell body 1, a liquid inlet 2, a liquid outlet 3, multiple sets of detection holes 4, separators 5, and multiple sets of magnetic heads. 6 and temperature sensor 7.

[0016] Installation method:

[0017] The conductance cell body 1 is provided with a ring heating coil, the liquid inlet 2 and the liquid outlet 3 are respectively installed on both sides of the conductance cell body 1, the level of the liquid outlet 3 is higher than that of the liquid inlet 2, and multiple sets of detection holes 4 Set on the surface of the conductance cell body 1, the separator 5 is installed at a distance of 15cm from the bottom of the conductance cell body 1, multiple sets of magnetic heads 6 are installed at the bottom of the conductance cell cell body 1, and are vertically distributed with multiple sets of detection holes 4, and the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com