Method for automatically adjusting position of paving material of storage cabinet

An automatic adjustment and laying technology, applied in control/regulation systems, instruments, comprehensive factory control, etc., can solve the problems of simultaneous storage of multiple small batches, automatic adjustment of batch weight, and inaccurate control, etc. , to achieve the effect of reducing production waiting time, maximizing the use of storage cabinet space, and simplifying the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, storing a single batch

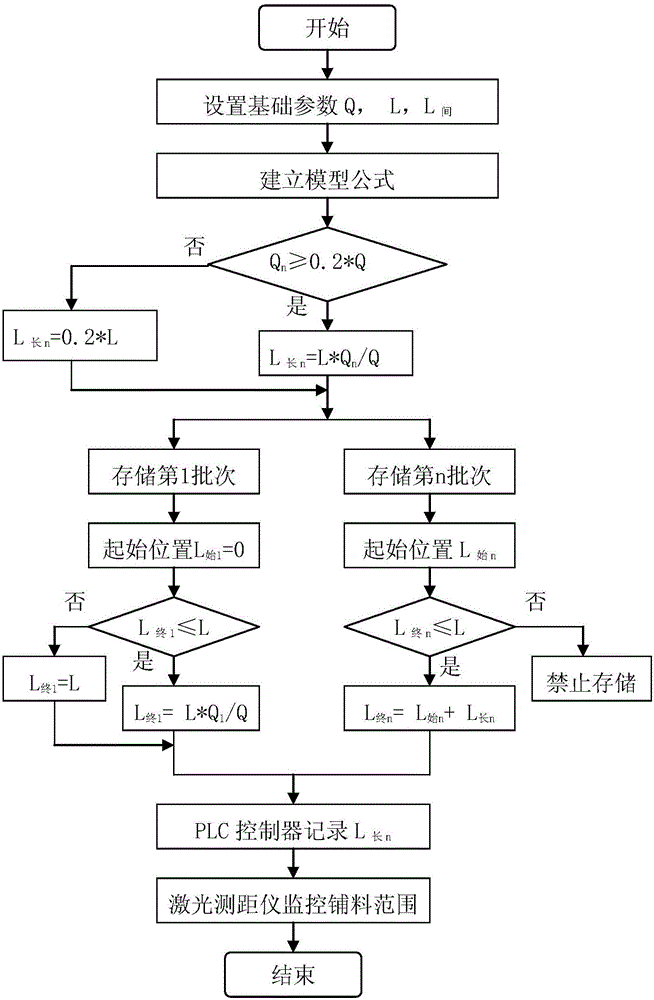

[0021] Such as figure 1 As shown, set the basic parameters, set the total weight of the normal batch in the PLC controller Q = 6000kg, the length of the full cabinet spread L = 12m, and the distance L between multiple batches of materials entering the same storage cabinet 间 = 2m;

[0022] The batch material weight Q 1 =3000kg, calculate L 长1 =L*Q 1 / Q=6m, the starting position of laying material is at the discharge end L of the storage cabinet 始1 =0, end position L 终1 = L 长 = 6m, so the paving range is between 0m and 6m;

[0023] If the batch material weight Q 1 =6200kg, Q 1 >Q, it can be calculated that L 长1 =12.4m, beyond the maximum allowable paving range, take L for this 长1 =12m, the range of material spreading is between 0m and 12m, allowing full container material spreading;

Embodiment 2

[0024] Embodiment 2, storing multiple batches

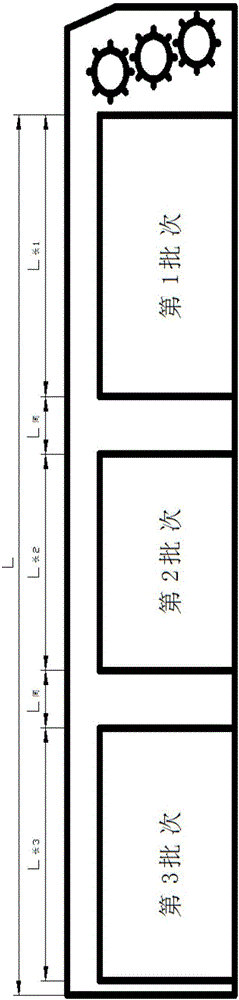

[0025] Such as figure 2 As shown, select the first batch of materials to enter the storage cabinet, and the weight of the materials is Q 1 =1500kg, calculate L 长1 =L*Q 1 / Q=3m, the paving range is between 0m and 3m;

[0026] Select the second batch of materials to enter the storage cabinet, and the weight of the materials is Q 2 =1000kg, due to Q 2 长2 =0.2*L=2.4m, the distance between the starting position of laying material and the end position of the first batch of material is L 间 =2m, so the starting position of paving is L 始2 = L 间 +L 长1 =5m,L 终2 = L 始2 +L 长2 =7.4,m, so the laying range of the second batch of materials is between 5m and 7.4m;

[0027] Select the third batch of materials to enter the storage cabinet, and the weight of the materials is Q 3 =1800kg,L 长3 =L*Q 3 / Q=3.6m, the initial position of paving is L 始3 = L 间 *2+L 长1 +L 长2 =9.4m, L 终3 = L 始3 +L 长3 = 12m, so the laying range of the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com