A kind of integral warp knitted spacer fabric sterilization filter material and preparation method thereof

A warp-knitted spacer fabric and filter material technology, applied in the field of filter materials, can solve problems such as the filling density cannot be maximized, the lack of reinforcement of the base fabric, and the strength of the filter material is not very good, so as to achieve excellent filling of the storage space, excellent Water permeability, high adsorption and impurity removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Knitting by the empty thread method, on the karl Mayer RD6DPLM / 30-N E12 machine, the gauge of the needle bed is adjusted to 20mm, and the knitting density is 5wpc.

[0045]

[0046] Raw materials and air wear:

[0047]

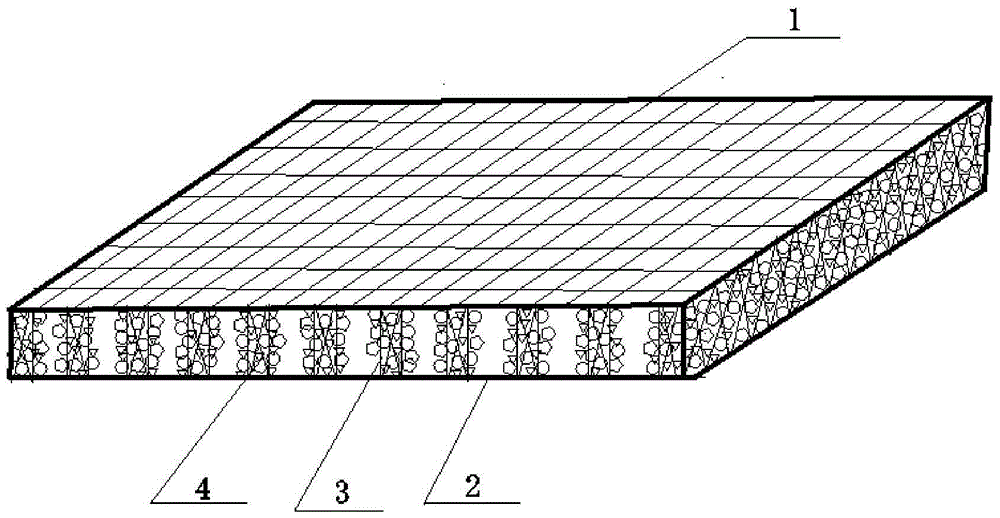

[0048] The appearance and shape of the multi-effect filter material of the warp-knitted spacer fabric are similar to figure 1 , both the upper layer 1 and the lower layer 2 have a mesh structure, and the mesh structure makes the filter material have excellent water permeability and air permeability.

Embodiment 2

[0050] The connecting yarn bar is used to knit at different rows of the front and rear needle beds. On the karl Mayer RD6DPLM / 30-NE12 machine, the needle bed gauge is adjusted to 20mm, and the knitting density is 6wpc.

[0051]

[0052]

[0053] Raw materials and air wear:

[0054]

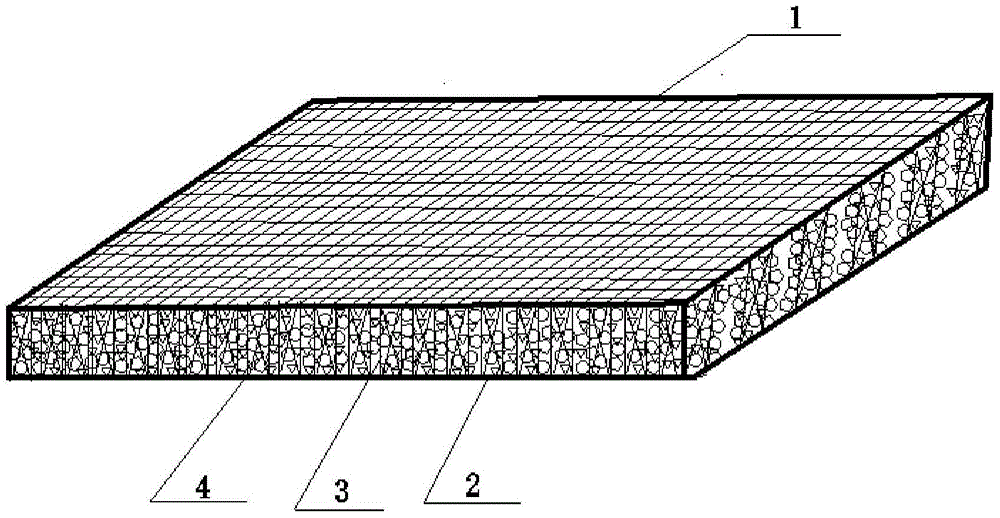

[0055] The appearance and shape of the integral warp-knitted spacer fabric multi-effect filter material are similar to figure 2 , the upper layer 1 and the lower layer 2 are both dense structures, the design of the dense structure and the use of ultra-fine fibers make the filter material have excellent deep filtering effect and surface filtering effect. efficient filter material.

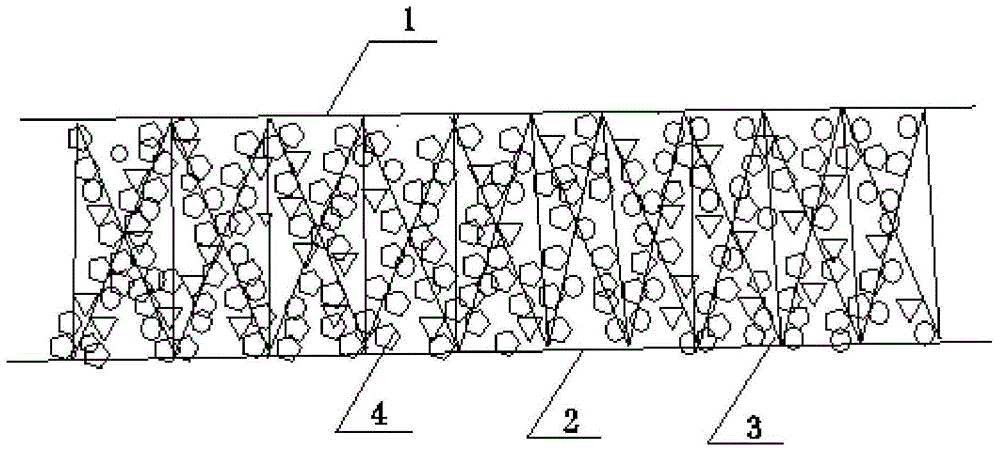

[0056] The appearance of the integral warp-knitted spacer fabric multi-effect filter material is as follows figure 1 , figure 2 The schematic diagram of the adsorption of the skin-core bicomponent polyester monofilament on the coconut shell amorphous granular activated carbon is shown in Fig. image 3 sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com