contact image sensor

An image sensor and contact technology, applied in the field of image sensors, can solve problems such as the complex and bulky structure of the contact image sensor, and achieve the effect of improving the imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

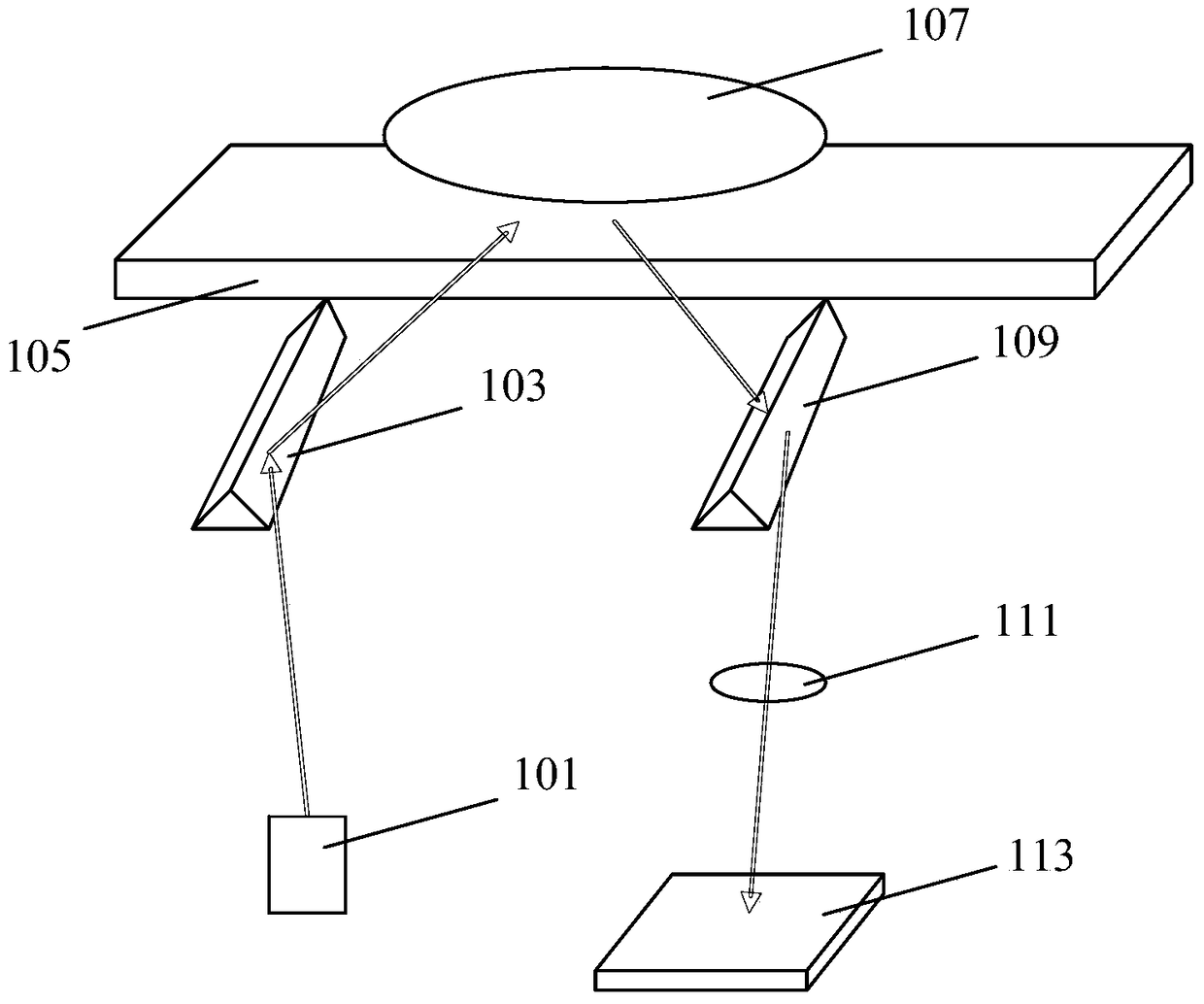

[0033] When the contact image sensor performs image acquisition, the object to be collected is closely attached to the surface of the image sensor, and the external light source cannot shine on the object and the surface of the sensor through the opaque object. Moreover, in order to ensure that the image sensor chip only receives light reflected from objects, it is required that the back of the pixel of the image sensor chip cannot transmit light, that is, the light cannot directly irradiate the pixels on the surface of the image sensor chip from the back of the image sensor chip. Therefore, existing contact image sensors usually use figure 1 The complex structure shown. However, this complex structure is bulky and thick, which does not conform to the trend of thinner and lighter electronic products, and it is difficult to integrate this complex structure with other electronic products, so its application is greatly limited.

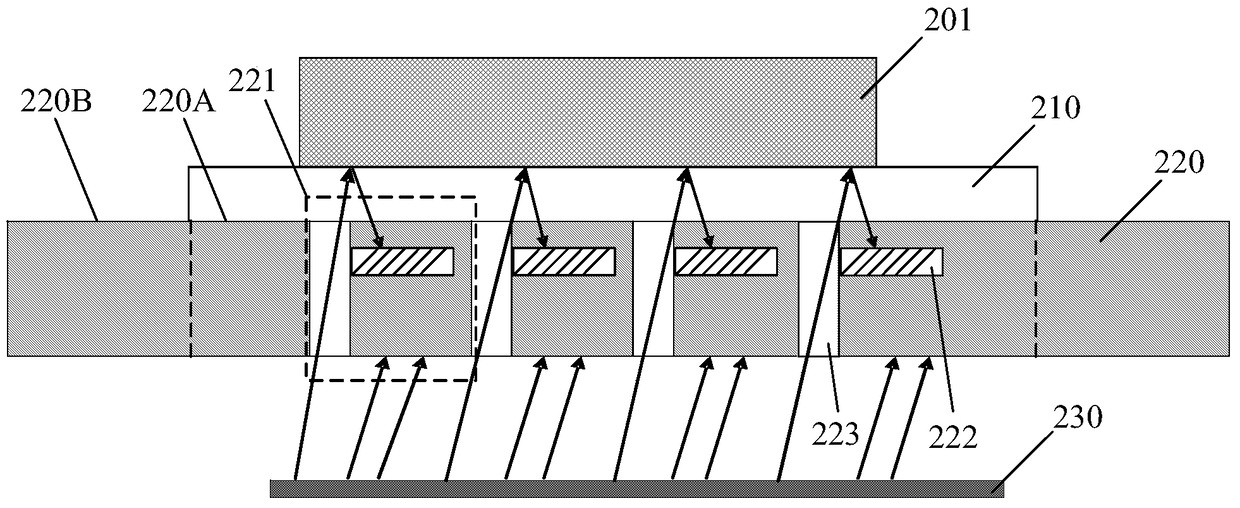

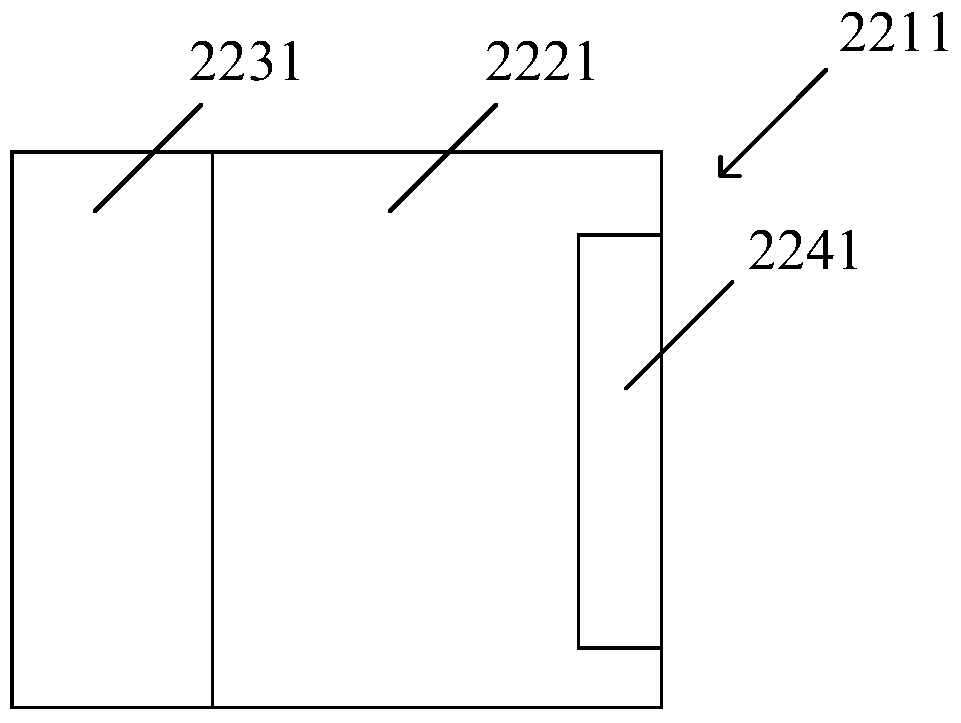

[0034] To this end, the present invention provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com