OLED packaging structure, display device and packaging method

A technology of encapsulation structure and encapsulation method is applied in the direction of material analysis, testing water content, electrical components, etc. by observing the impact on chemical indicators, which can solve problems such as difficulty in judgment, intrusion of water vapor in OLED device packaging, and achieve convenient screening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

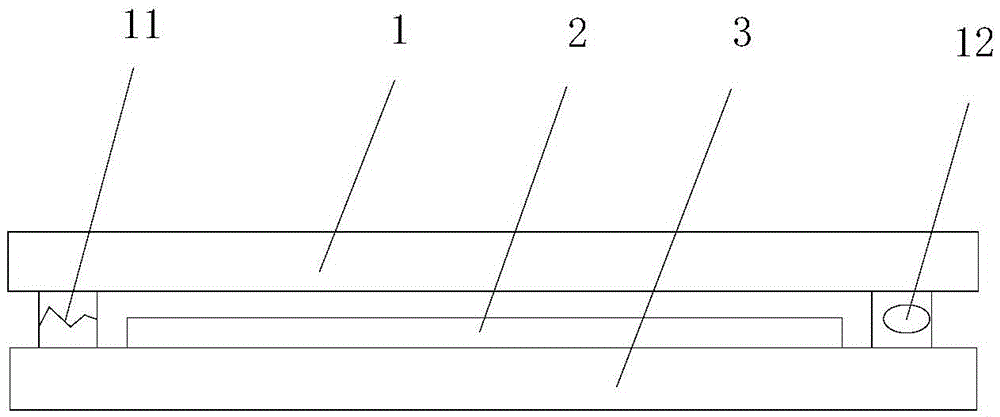

[0033] Such as Figure 2-3 As shown, the OLED packaging structure provided in this embodiment includes a substrate 3, a cover plate 1, and a packaging unit arranged between the substrate 3 and the cover plate 1; a display component 2 (OLED, TFE, etc.) is arranged on the substrate 3 ), the encapsulation unit encapsulates the periphery of the display component 2; moreover, the interior of the encapsulation unit includes at least one moisture-sensitive layer 5, and the moisture-sensitive layer 5 changes color when exposed to water. By observing the discoloration of the water vapor sensitive layer 5, the problem of difficult judgment of water vapor intrusion into the OLED device package is effectively solved, and the device package structure can be easily analyzed.

[0034] It is worth noting that in this embodiment, it is only necessary to add the water vapor sensitive layer 5 (water-absorbing discoloration agent) to the packaging unit, which is not only beneficial to the correct...

Embodiment 2

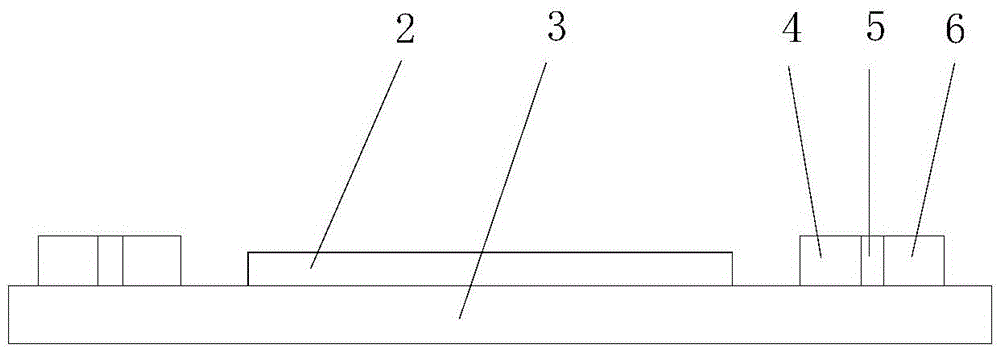

[0043] Such as Figure 4 As shown, the technical content of the second embodiment is the same as that of the first embodiment and will not be described repeatedly. The content disclosed in the first embodiment also belongs to the content disclosed in the second embodiment. Another structure is specifically as follows.

[0044] The packaging unit includes a first sealing layer 6, a water vapor sensitive layer 5 and a third sealing layer 7; wherein, the first sealing layer 6 is arranged on the periphery of the display component 2; the third sealing layer 7 is arranged above the display component 2 And it is filled between the substrate 3 and the cover 1 (area AA between the substrate 3 and the cover 1 ); the water vapor sensitive layer 5 is disposed between the first sealing layer 6 and the third sealing layer 7 . Other specific features have been described in detail above and will not be repeated here. In this encapsulation structure, water vapor-sensitive materials are mixed...

Embodiment 3

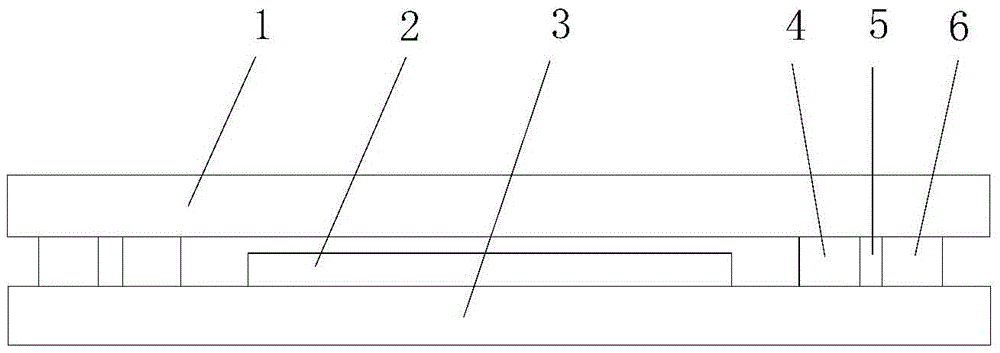

[0049] Embodiment 3 is further modified on the basis of Embodiment 1 and Embodiment 2. The packaging unit includes a first sealing layer 6, a water vapor sensitive layer 5, a second sealing layer 4 and a third sealing layer 7, and the first sealing layer 6, the water vapor sensitive layer 5 and the second sealing layer 4 are sequentially arranged on the display from outside to inside. Periphery of the component 2 ; the third sealing layer 7 is disposed above the display component 2 and filled between the substrate 3 and the cover plate 1 . It can be seen that the encapsulation structure using four layers in this embodiment can also judge the encapsulation effect of the OLED by observing the discoloration of the water vapor sensitive layer 5 .

[0050] It is worth noting that the number of sealing layers in the above-mentioned packaging unit is not limited, and can be flexibly set according to actual needs, as long as the water vapor sensitive layer 5 is included.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com