Cake tearing machine under column pressure

A steamed bun and steamed bun machine technology, which is applied in the division/slicing of baked food, can solve the problems of affecting the taste, the steamed buns are difficult to taste, and the steamed buns have edges and corners, etc., so as to save manpower, have a good taste and be easy to taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

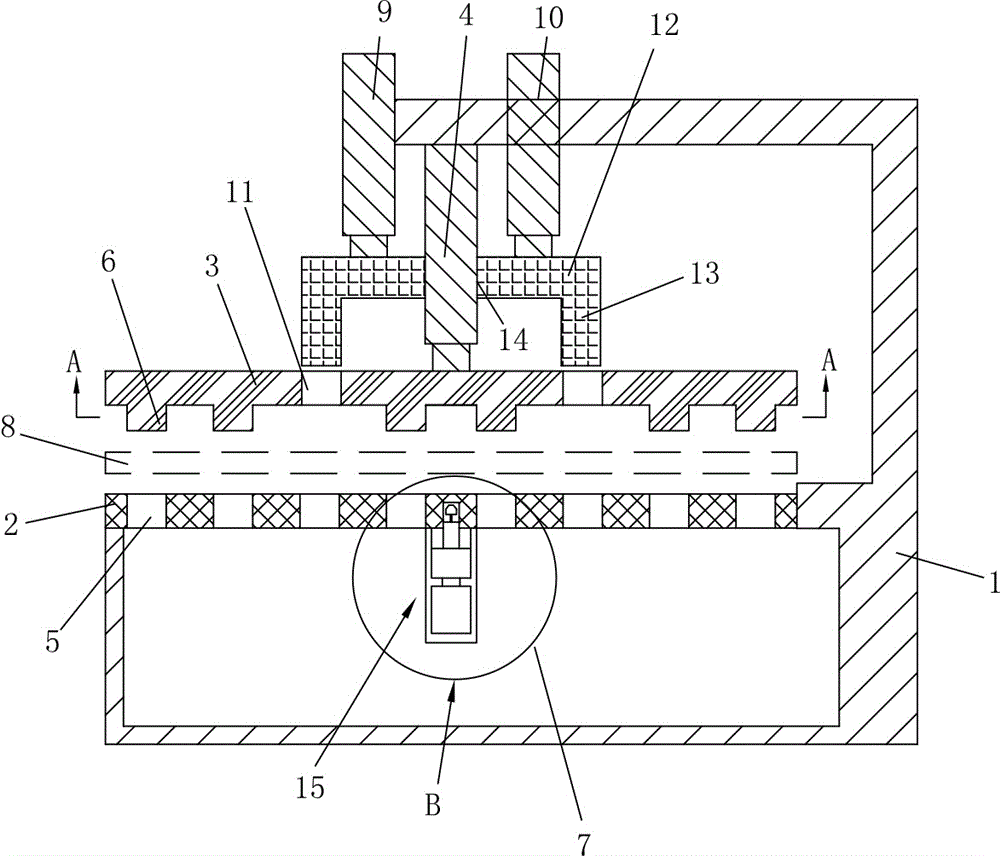

[0014] Please refer to Figure 1-3 , Embodiment 1 of the present invention includes:

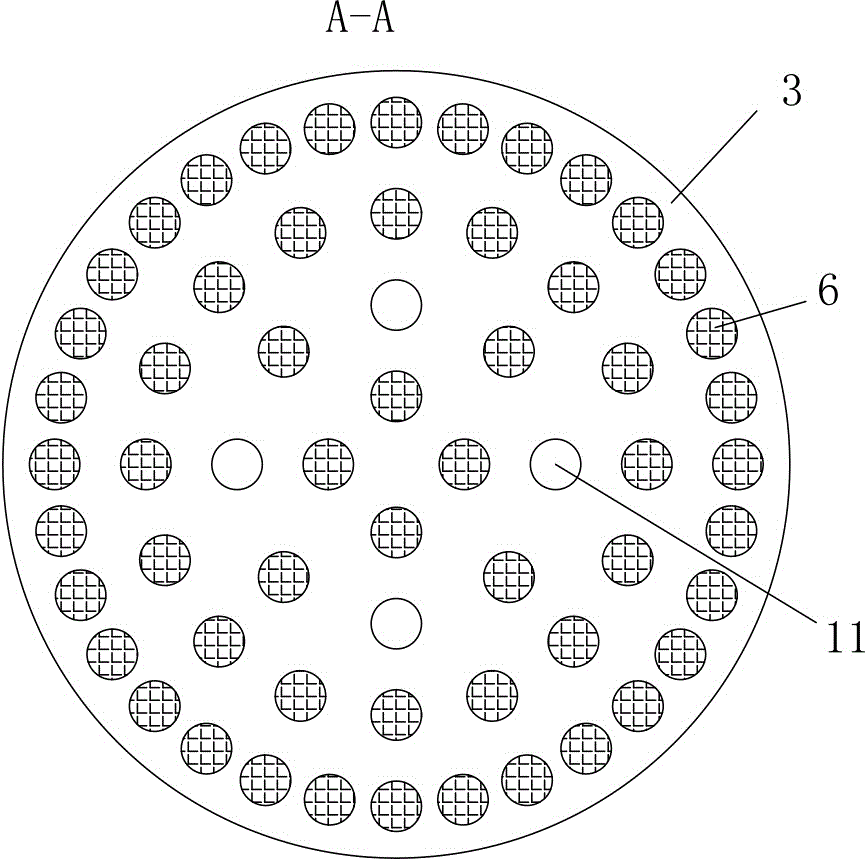

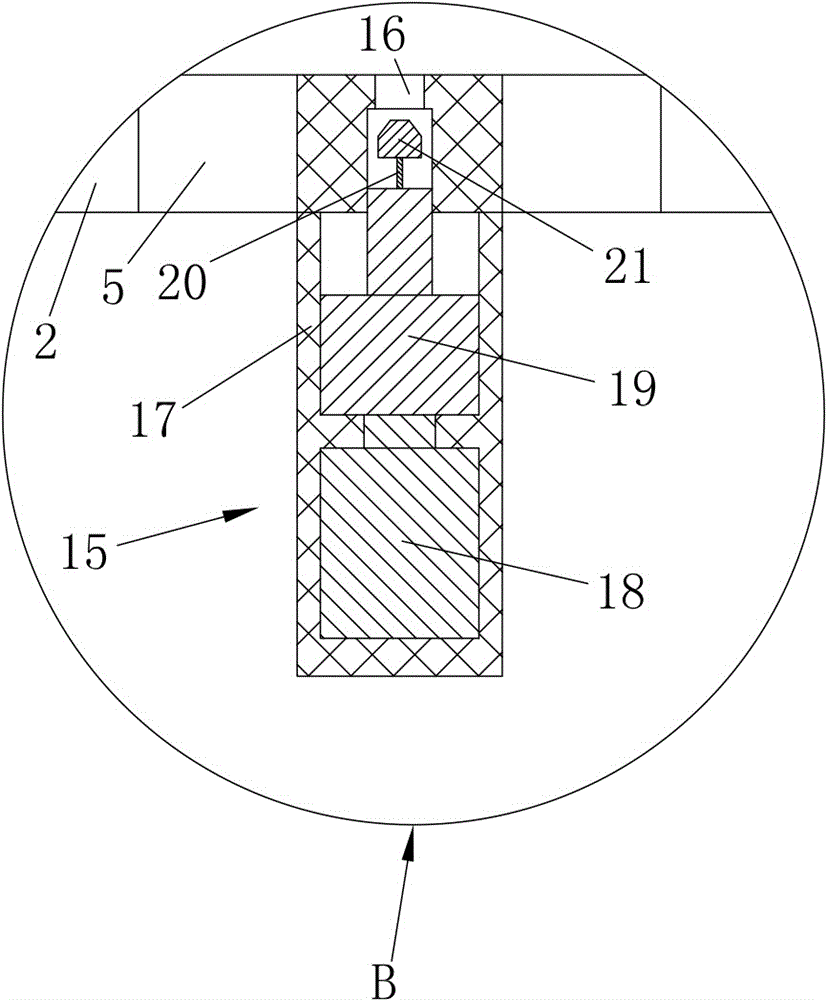

[0015] A steamed bun breaking machine with column pressure, comprising a machine platform 1, a bottom backing plate 2 and a top pressing plate 3, the bottom backing plate 2 is fixed on the machine platform 1, and the big steamed buns 8 to be broken are placed on the bottom backing plate 2 On the upper surface, the top pressure plate 3 is connected to the machine 1 through the cylinder one 4, and the bottom backing plate 2 is provided with evenly arranged circular through holes 5, and the top pressure plate 3 is provided with cylindrical holes 5 that match the bottom backing plate 2. Protrusion 6, the diameter of columnar projection 6 is 3mm, and the diameter of round through hole 5 is bigger than the diameter of columnar projection 6 0.5mm; Machine table 1 is also provided with the finished product storage box 7 that is used to receive small steamed bun block; Top Four upper through holes 1...

Embodiment 2

[0017] Embodiment 2 of the present invention includes:

[0018] A steamed bun breaking machine with column pressure, including a machine table, a bottom backing plate and a top pressing plate, the bottom backing plate is fixed on the machine table, the big steamed buns to be broken are placed on the top of the bottom backing plate, and the top pressing plate passes through the cylinder 1. Connected with the machine, there are evenly arranged round through holes on the bottom backing plate, and cylindrical protrusions on the top pressure plate that match the round through holes on the bottom backing plate. The diameter of the cylindrical protrusions is 5mm, and the diameter of the round through holes is The diameter is 1.2mm larger than the diameter of the cylindrical protrusion; there are four upper through holes on the top pressure plate, and a lower pressing block is arranged above the upper through holes, and the lower pressing block is connected with the second cylinder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com