Rice grading and fine selection screen

A technology for rice and sieve grids, applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of inability to clean rice bran powder agglomerates, etc., and achieves the effects of low cost of transformation, excellent quality, and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

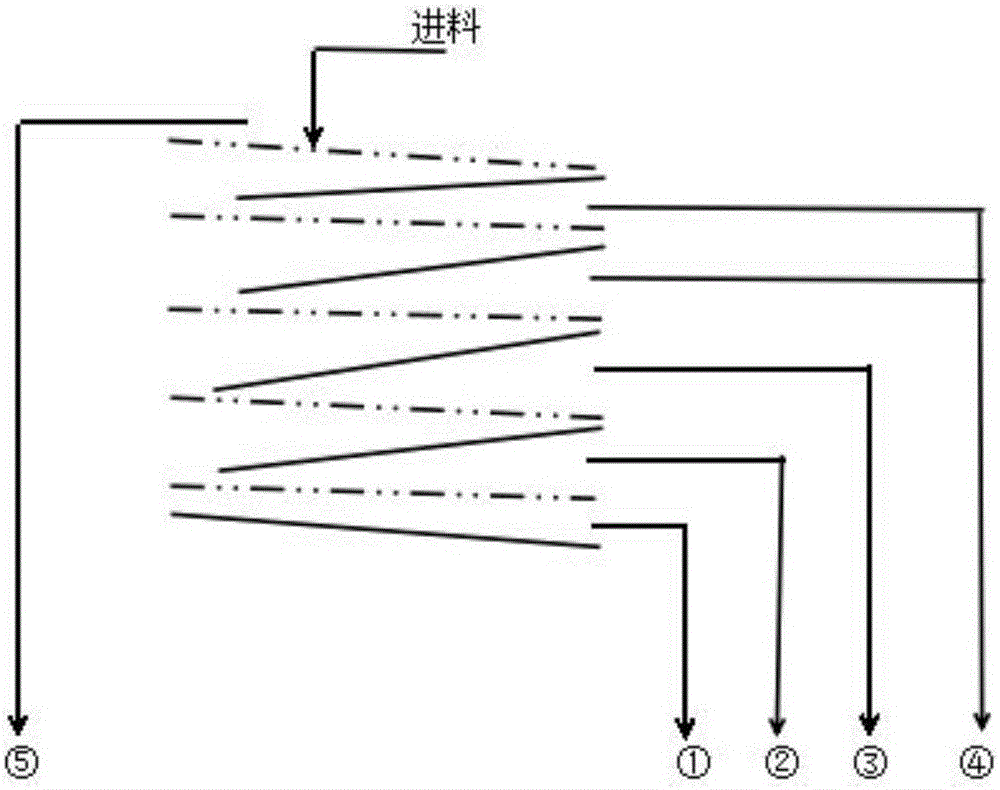

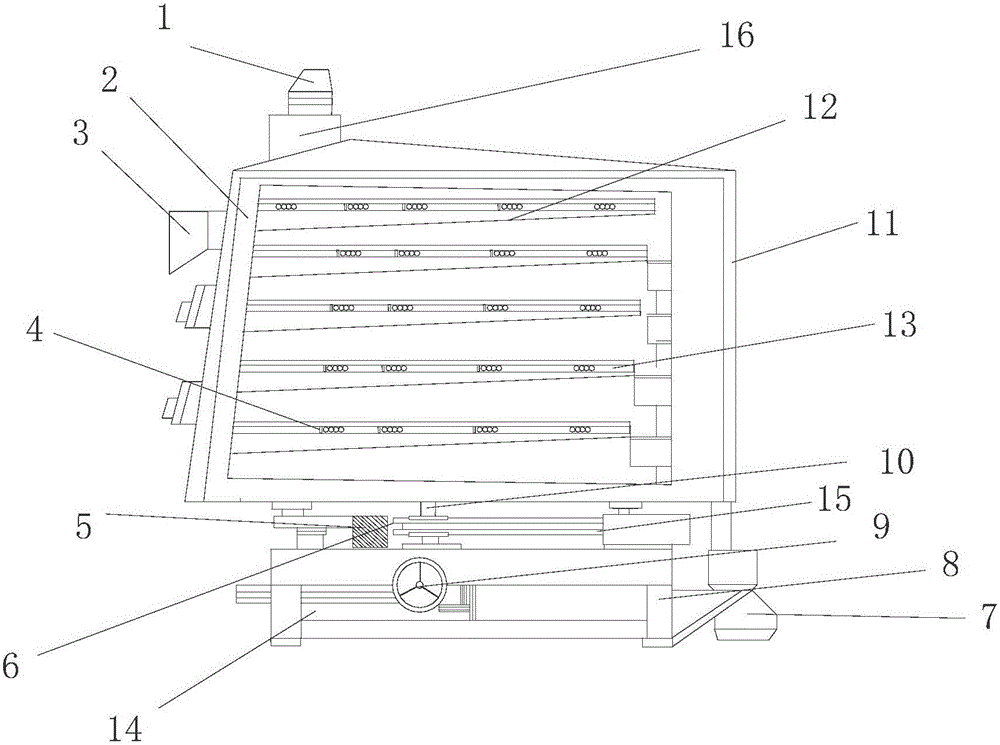

[0013] refer to figure 1 , the rice selection sieve of the present invention, comprises the power mechanism that is located in the frame (8) and is arranged at the grading selection mechanism in the screen body (13) above the frame (8) and forms; The power mechanism is included in the frame The motor (14) is fixed, the speed regulating mechanism (10) driven by the motor (14), the speed regulating mechanism (10) manipulated by the speed regulating tension mechanism (9) passes through the transmission belt (15) and the bridge transmission mechanism ( 6) are connected, and the bridge transmission mechanism (6) forms a transmission relationship with three sets of eccentric rotary mechanisms (5) through the transmission belt (15), and drives the classification and selection mechanism to perform plane rotary motion; the classification and selection mechanism is included in the sieve body (13) is provided with a sieve grid (4) with a certain inclination angle and a sieve hole, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com