Plastic hose automatic cutting device

A technology of automatic cutting device and plastic hose, which is applied in metal processing and other directions, can solve the problems of time-consuming and labor-consuming, low processing efficiency, and poor accuracy of manual tool setting, so as to improve the fixing effect, improve work efficiency and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

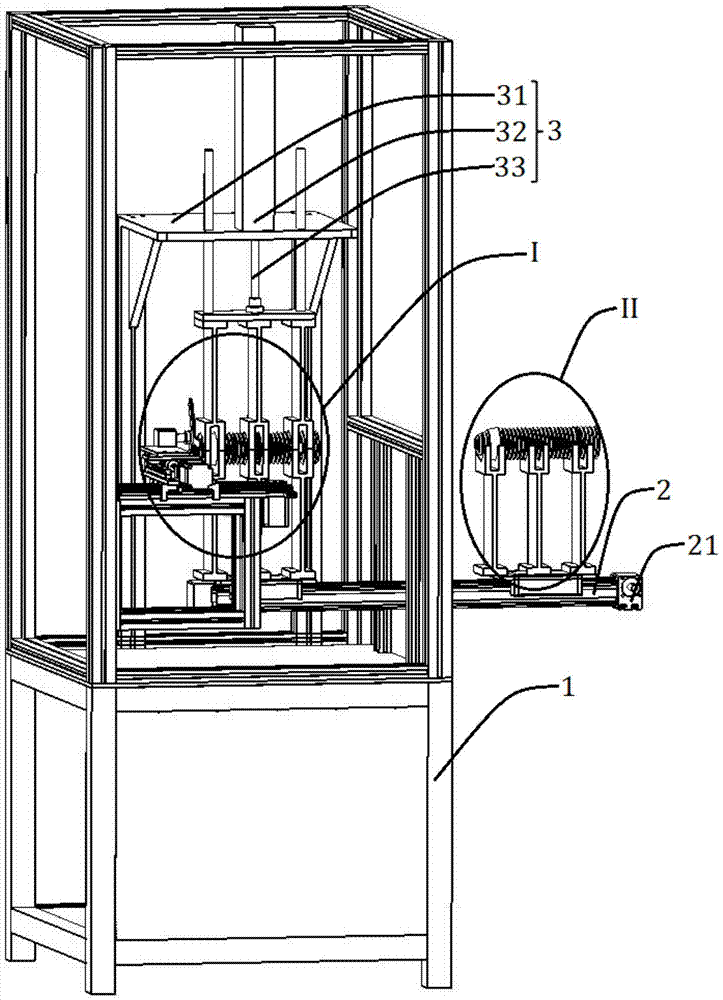

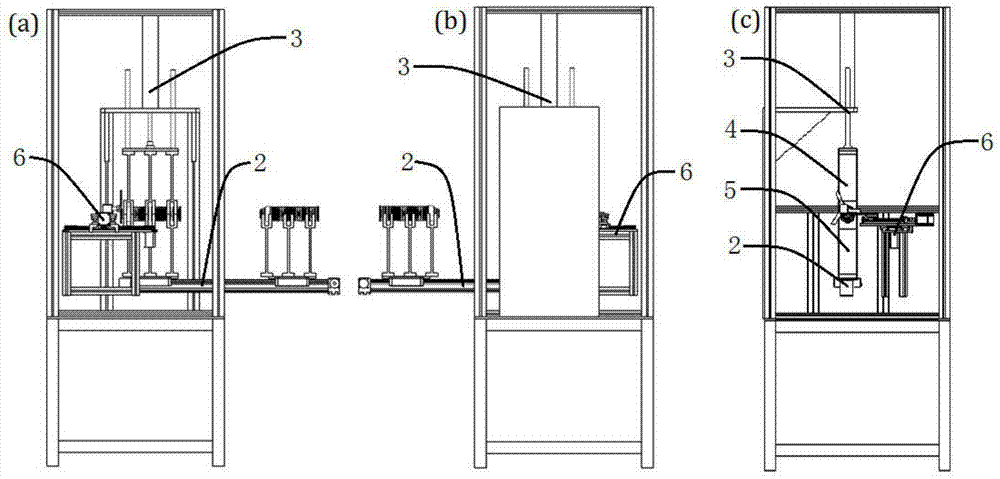

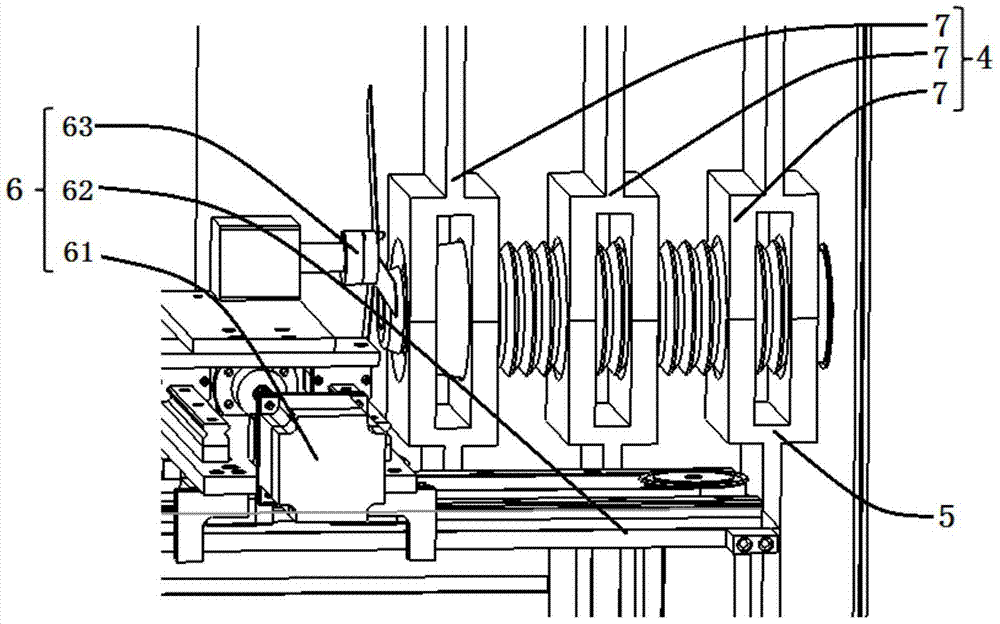

[0025] Such as figure 1 with figure 2 As shown, this embodiment includes: a frame 1, a rack material guide rail 2, an electric push rod 3, an upper fixing mechanism 4, a lower fixing mechanism 5 and a cutting mechanism 6, wherein: the rack material guide rail 2 and the cutting mechanism 6 are relatively arranged and fixed On the frame 1, the electric push rod 3 is slidingly connected with the frame 1, the bottom of the upper fixing mechanism 4 is fixedly connected with the electric push rod 3, and the bottom of the lower fixing mechanism 5 is fixedly connected with the frame guide rail 2;

[0026] The upper fixing mechanism 4 and the lower fixing mechanism 5 are of symmetrical structure, and the two pieces cooperate with each other and are fixed by clamping molds.

[0027] The racking material guide rail 2 is provided with a guide rail motor 21, and the guide rail motor 21 drives the racking material guide rail 2 to rotate and convert it into a horizontal linear reciprocatin...

Embodiment 2

[0035] Such as Image 6 As shown, according to the different cutting objects, the structure of the upper fixing mechanism 4 and the lower fixing mechanism 5 can be changed accordingly; when the cutting object is a smooth plastic hose, in order to fix it, the upper fixing mechanism 4 and the lower fixing mechanism Mechanism 5 is designed as an integral structure, and the internal size is determined according to the cutting object; the internal shape of upper fixing mechanism 4 and lower fixing mechanism 5 can also be an infinitely enlarged trapezoidal cylinder, so as to realize the cutting of irregular soft bodies.

[0036] Such as Figure 7 with Figure 8 As shown, the upper fixing mechanism 4 and the lower fixing mechanism 5 are all integrally formed, including: support plates 81 on both sides and several support clamping plates 82 connecting the support plates 81 on both sides; the support plates 81 are provided with The draw-in slot 83 that the frame guide rail 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com