Novel lightning plug and manufacturing method thereof

A plug, a new type of technology, applied in the direction of fixed connection, fixed/insulated contact components, circuits, etc., can solve the problems of PIN position easy to fall off, difficult welding operation, low welding efficiency, etc., to achieve convenient welding operation and high welding accuracy , The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

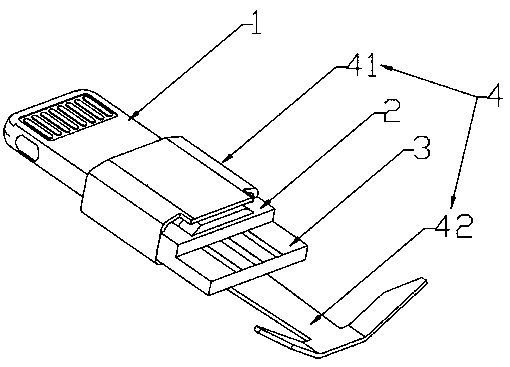

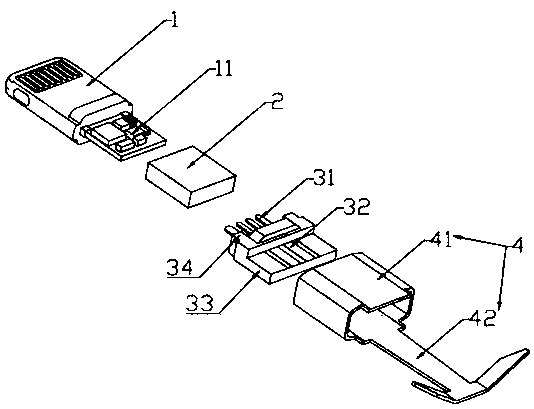

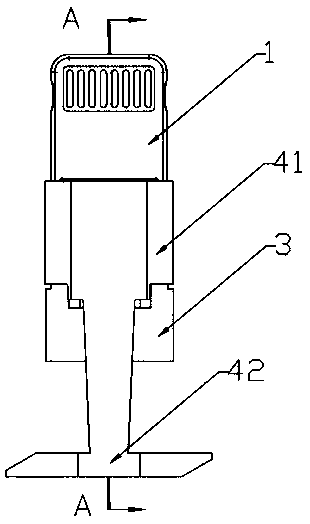

[0027] Figure 1-Figure 4 A new type of lightning plug 1 shown includes a lightning plug 1, a protective layer 2, an adapter part 3 and a wire fixing part 4. One end of the lightning plug 1 is provided with a PCB board 11, and the surface of the PCB board 11 is provided with electronic components. The back is provided with a number of PIN pads 12 arranged in sequence,

[0028] The protective layer 2 is made of low-pressure injection molding material, and is injected on the surface of the PCB board 11 through a low-pressure injection molding process to protect the electronic components on the surface of the PCB board 11; the protective layer 2 is injected using a low-pressure injection molding process to avoid damage to the PCB board during the injection molding process The electronic components on the surface of 11, after in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com