Film pasting method, film pasting device and display screen

A technology of a film sticking device and a display screen, which is applied in packaging and other directions, can solve the problems of limited alignment accuracy, difficulty in ensuring the alignment of the optical film 12, and affecting the aesthetics of the screen 11, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] As mentioned in the background, the film sticking method in the prior art cannot realize that the optical film completely covers the surface of the screen and is fully bonded to the screen.

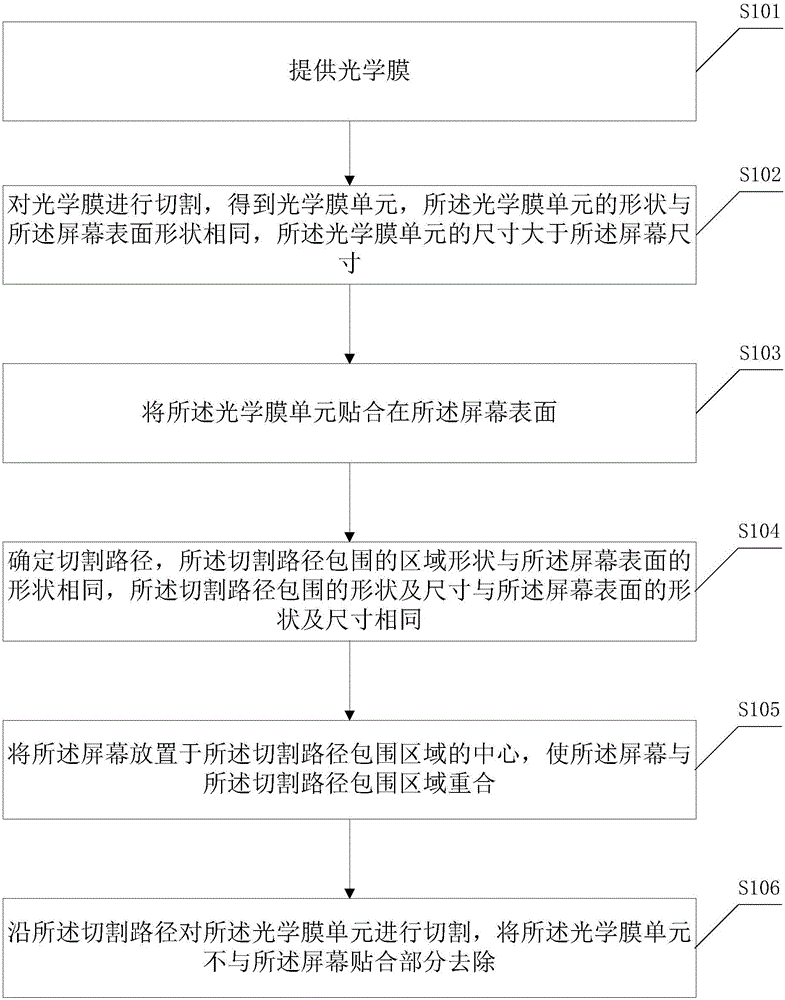

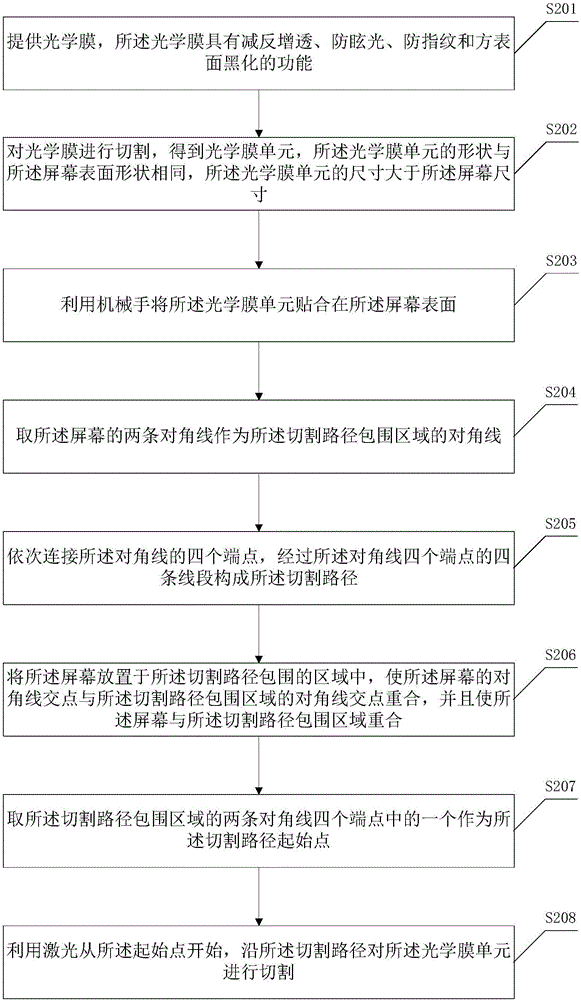

[0059]In view of this, an embodiment of the present invention provides a method for pasting a film, which is applied to a screen surface film, including:

[0060] Provide optical film;

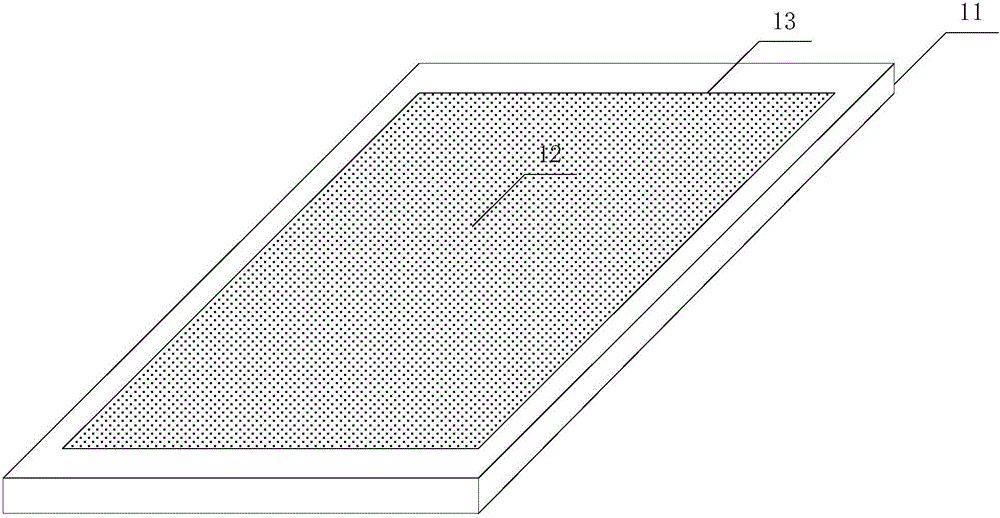

[0061] cutting the optical film to obtain an optical film unit, the shape of the optical film unit is the same as the surface shape of the screen, and the size of the optical film unit is larger than the screen size;

[0062] attaching the optical film unit to the screen surface;

[0063] Determine a cutting path, the shape of the area surrounded by the cutting path is the same as the shape of the screen surface, and the shape and size surrounded by the cutting path are the same as the shape and size of the screen surface;

[0064] placing the screen at the center of the cutting path enclosing ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com