Adjustable weighing and supporting device for construction hoist

A technology for construction lifts and support devices, applied in lifts, transportation and packaging, etc., can solve problems such as the self-weight of the guide rail frame, and achieve the effects of simplifying manufacturing, convenient connection, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

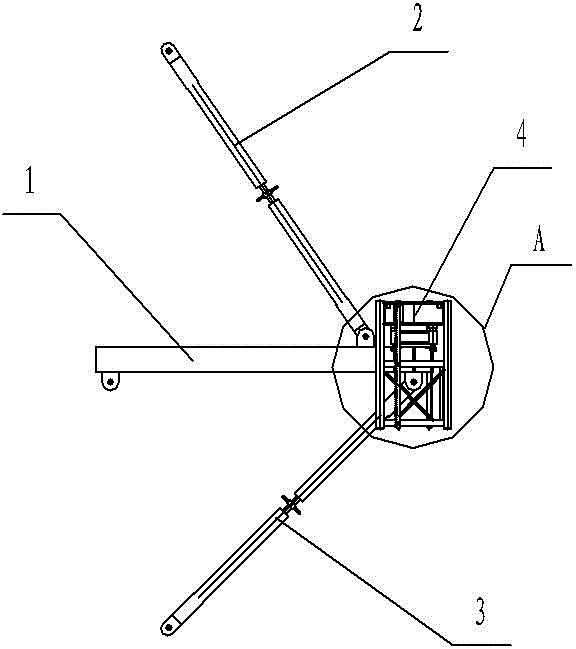

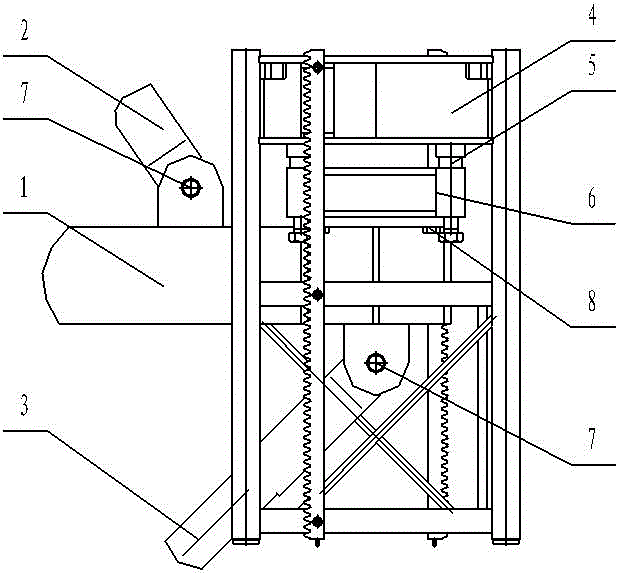

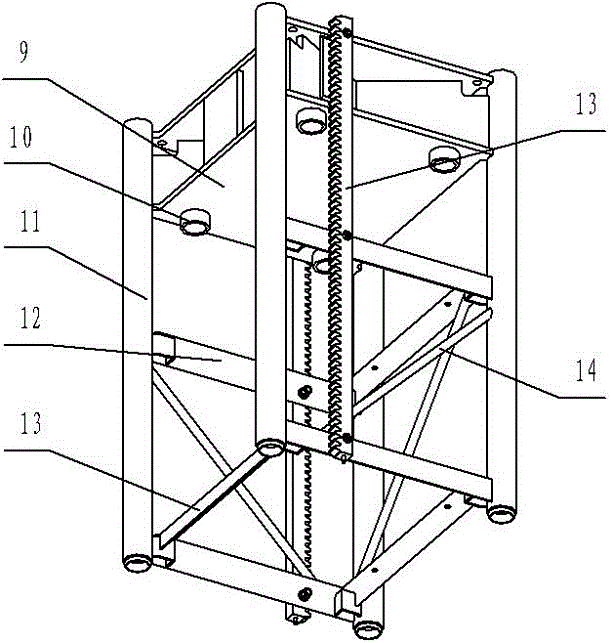

[0021] This embodiment provides an adjustable weighing support device for a construction lift, such as figure 1 with figure 2 As shown, it includes a tie rod 2, a strut 3, a support seat 1, a pressure sensor 5, an adjustment device 6 and a load-bearing standard section 4, and one end of the tie rod 2 and the strut 3 is respectively connected to the support seat corresponding to one end of the support seat 1 through a pin shaft 7. The ear plate 18 is hinged, and the end of the support seat 1 is connected to the adjustment device 6 through the bolt 8. The adjustment device 6 is arranged between the upper and lower adjacent load-bearing standard sections 4, and the pressure sensor 5 is arranged between the adjustment device 6 and the upper load-bearing standard section. Sections and / or the joints between the lower load-bearing standard sections, the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com