Segment Dyeing Technology of Short Color Distance Segment Dyeing Yarn

A yarn dyeing and process technology, which is applied to the field of segment dyeing process of short color spacing segment dyeing yarn, can solve the problems of impure color, lack of high temperature fixing process for dyed cotton with reactive dyes, and inability to guarantee the color fastness of cotton yarn, etc. Effects of color and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0023] The section dyeing process of the short color distance section dyeing yarn disclosed by the present invention comprises the following steps:

[0024] 1. The pretreatment of the yarn makes the moisture content of the yarn consistent, making the subsequent dyeing more uniform.

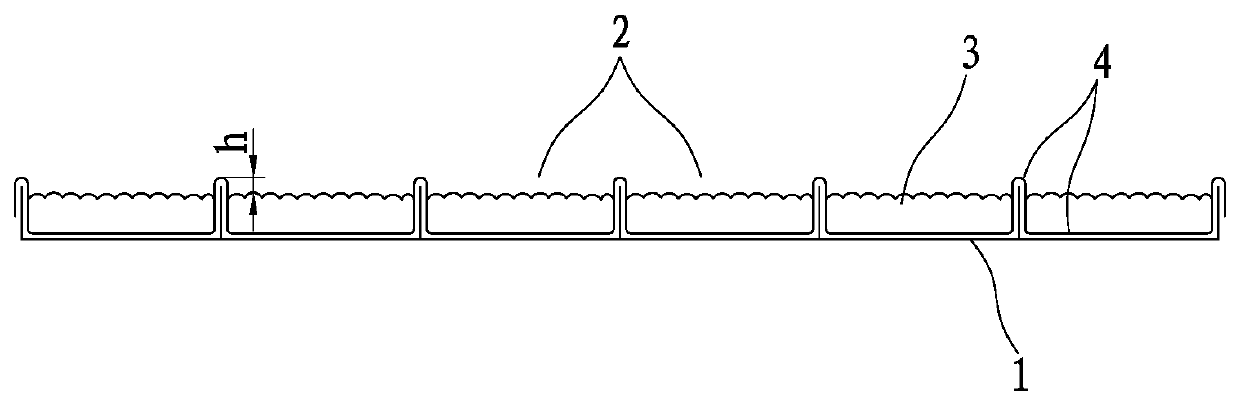

[0025] Second, weaving yarn, such as figure 1 As shown, a plurality of spacers 2 are arranged in the tray 1 according to the distance between two adjacent color segments. The method of plate pressing is used to press the yarn 4 until it is attached to the surface of each spacer 2, and the attachment can ensure the accuracy of the dyeing area.

[0026] 3. Dyeing liquid, according to the color scheme, pour dyes 3 of different colors into different compartments 2, and make the yarn fully dyed and evenly dyed by direct immersion. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com