Fabricated foundation with oblique-angle cone supports for power transmission tower, and construction method thereof

A power transmission tower and assembly technology, which is applied in the field of oblique pyramid support assembly foundation and its construction, can solve the problems that cannot meet the application requirements of emergency repair projects, the large amount of earthwork concrete and steel bars, and the difficulty of transporting concrete and steel bars, etc. Achieve the effect of good construction quality and economy, less concrete consumption, and small deformation and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

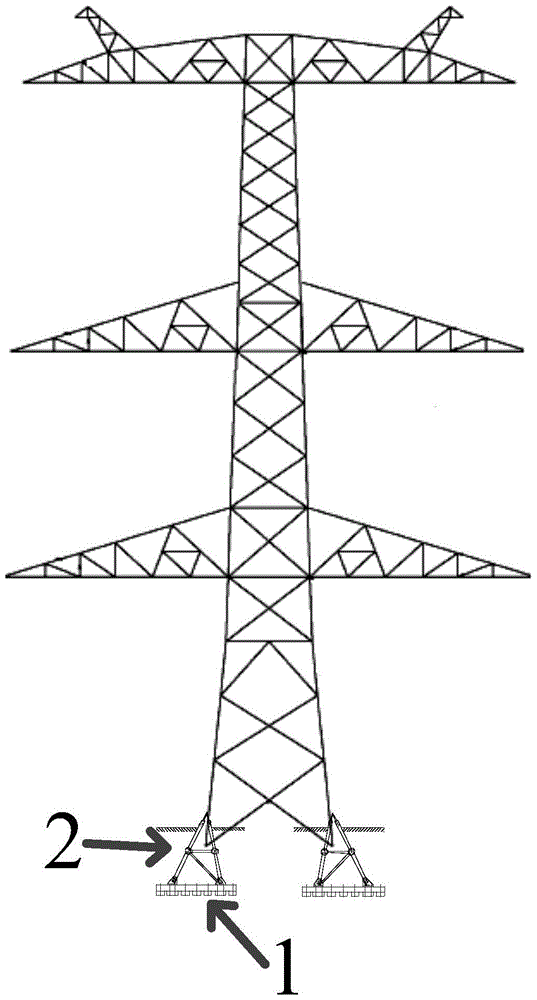

[0051] Such as figure 1 As shown, a kind of oblique pyramid bracket assembly foundation of a transmission tower, the transmission tower is provided with a tower body, a cross arm arranged perpendicular to the axial direction at the upper end of the tower body, and a tower arranged at the lower end of the tower body feet; the fabricated foundation is provided with a steel bracket 2 for fixing the base 1,

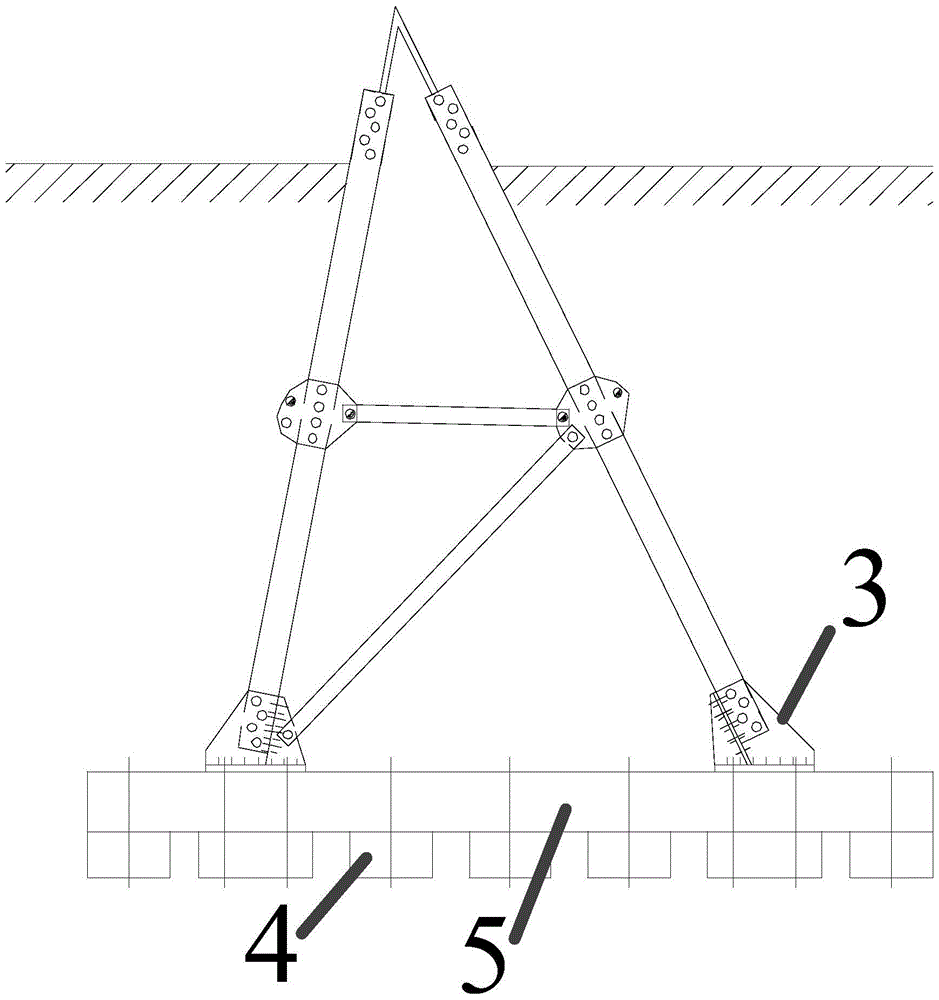

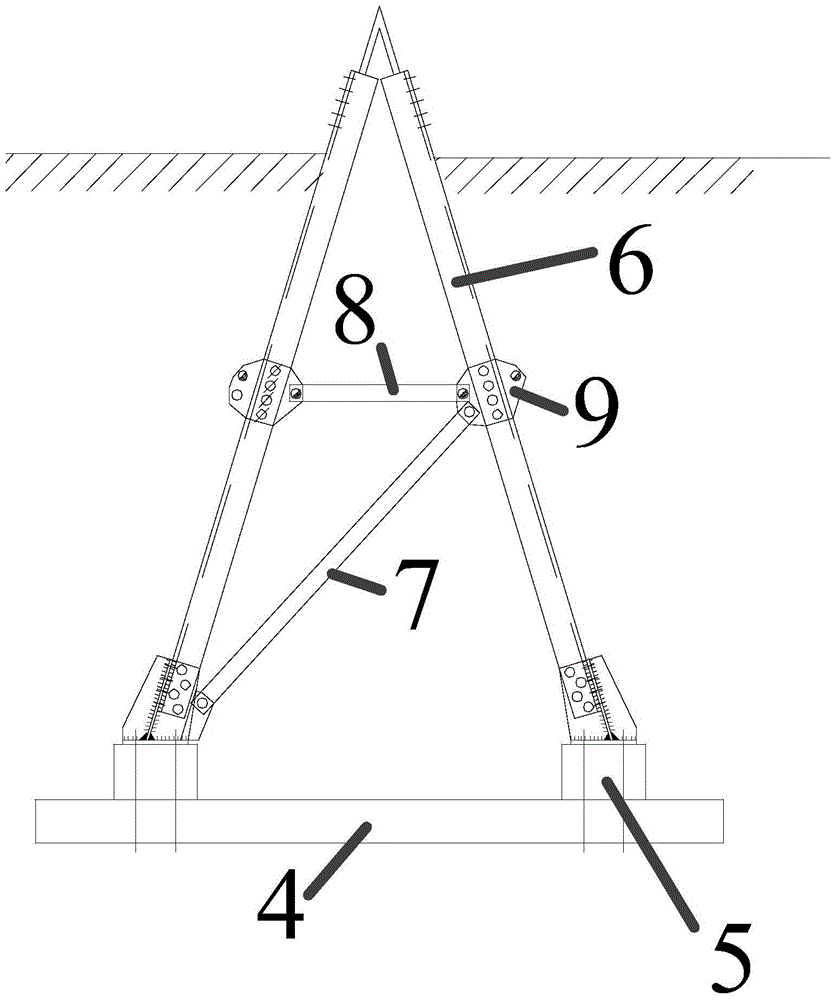

[0052] Such as figure 2 and image 3 As shown, the steel bracket 2 is a tower structure with an oblique triangle in longitudinal section, and its upper and lower ends are respectively provided with a fixing piece connected to the tower foot and a bracket fixing plate 3 connected to the fixed base 1;

[0053] Such as Figure 4 As shown, the fixed base 1 is composed of a horizontal fixed plate 4 arranged horizontally along the longitudinal direction and a fixed beam 5 arranged vertically on the upper side of the horizontal fixed plate 4 .

[0054] Such as image 3As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com