Composite stainless steel pipe provided with connecting pipes

A technology of stainless steel pipes and connecting pipes, applied in the direction of slender components, building components, etc., can solve the problems of sacrificing weight, bulky weight, increasing wall thickness, etc., and achieve the effects of ensuring strength, reducing weight, and reducing pipe wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

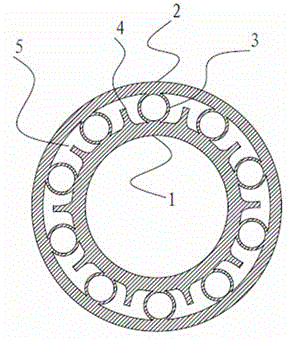

[0012] On the basis of Example 1, the preferred technical solution of the present invention also includes that a support piece 4 is provided on the outer wall of the inner tube 1, and the support piece 4 is arranged radially along the inner tube 1, and the support piece 4 and The connecting pipes 3 are arranged at intervals; a supporting distance 5 is set between the outer edge of the supporting piece 4 and the inner wall of the outer pipe 2 . Such a structure can make the pipe body have certain flexibility, and also can further strengthen its strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com